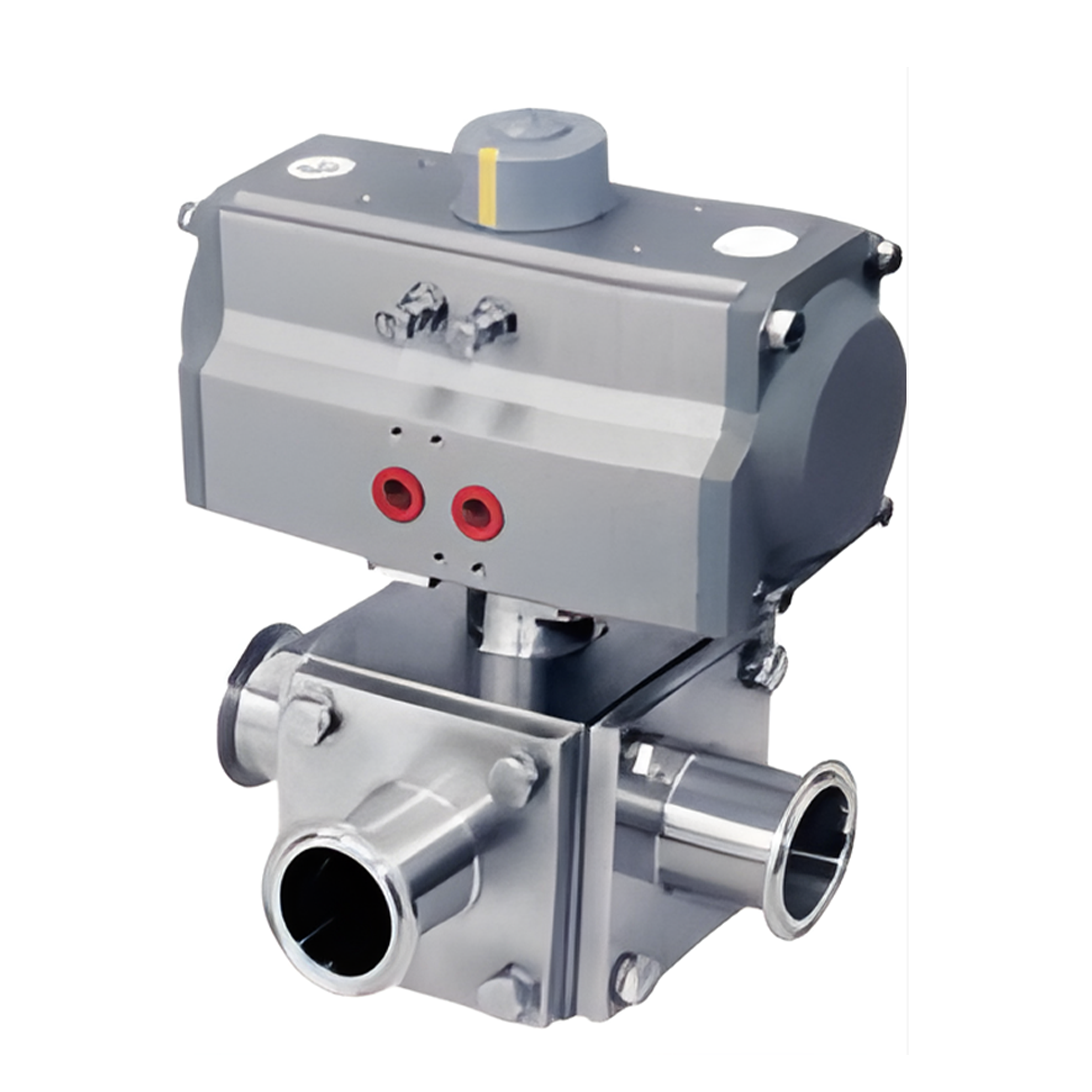

Injap Higienik Prestasi Tinggi untuk Pensanitasian Kritikal dalam Industri Makanan dan Farmaseutikal

Injap Higienik direkabentuk untuk memenuhi piawaian tertinggi pensanitasian dalam industri seperti pemprosesan makanan, farmaseutikal, dan pemprosesan biologi. Injap ini memastikan bahan kekal tidak tercemar dan mematuhi piawaian kebersihan peraturan semasa proses pemprosesan. Dengan rekabentuk yang memudahkan pembersihan, permukaan licin, dan tiada kawasan tersembunyi yang boleh menjadi tempat pembiakan bakteria, Injap Higienik mengelakkan pencemaran semasa pemindahan bendalir, menjamin keselamatan dan kualiti produk akhir. Injap ini adalah penting bagi kemudahan yang memerlukan pematuhan ketat terhadap piawaian kesihatan dan keselamatan.

Dapatkan Sebut Harga