- Overview

- Recommended Products

The AMZ pump features a classic rotary lobe pump design, built around a robust cast iron gearbox that ensures superior shaft rigidity and allows for easy oil seal replacement. Its universal gearbox configuration offers installation flexibility, enabling the inlet and outlet ports to be positioned either vertically or horizontally by simply adjusting the foot orientation.

To protect against environmental and corrosive damage, the gearbox exterior is coated with a high-quality epoxy paint system, providing long-lasting durability even in harsh operating conditions.

The standard AMZ configuration includes sanitary full-bore inlet and outlet ports, manufactured to international standards, which optimize flow efficiency and enhance Net Positive Suction Head (NPSH) performance. For demanding applications involving high-viscosity products, enlarged diameter or rectangular ports are also available.

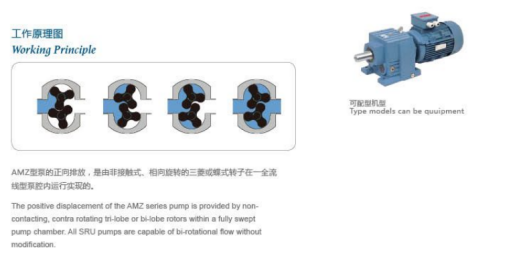

In its standard form, the AMZ pump is fitted with tri-lobe rotors, offering gentle and efficient handling of various fluids. For applications involving large or fragile solids, bi-lobe rotors are also available. All rotor types come in three temperature ratings, allowing the pump to be operated at maximum process temperatures of 70°C, 130°C, and 200°C — suitable for both product transfer and Clean-in-Place (CIP) operations.

| Maximum solid particle processing capacity | ||

| Maximum allowable particle size in the treatment of spherical solid materials(mm) | ||

| Disc-shaped rotor | Mitsubishi rotor | |

| AMZ-L1-025 | 9 | 6 |

| AMZ-L1-035 | 9 | 6 |

| AMZ-L1-048 | 11 | 6 |

| AMZ-L2-035 | 13 | 9 |

| AMZ-L2059 | 15 | 10 |

| AMZ-L2072 | 16 | 11 |

| AMZ-L3-080 | 22 | 15 |

| AMZ-L3-100 | 22 | 15 |

| AMZ-L3-125 | 30 | 20 |

| Corresponding table | ||||||

| displacement | Entrance and Connection | Maximum pressure | Maximum speed | |||

| End specifications | ||||||

| Ascend/Rotate | US gallon/100 RPM | Mm/inch | hope earnestly | psi | RPM | |

| AMz-L1/N1/025 | 0.147 | 3.88 | DN25/1' | 10 | 145 | 900 |

| AMz-L1/N1/035 | 0.208 | 5.49 | DN40V1.5' | 10 | 145 | 900 |

| AMz-L1/N1/048 | 0.286 | 7.55 | DN50/2' | 10 | 145 | 900 |

| AMz-L2N2/035 | 0.328 | 8.66 | DN40/1.5' | 15 | 215 | 900 |

| AMz-L2/N2/048 | 0.453 | 11.96 | DN50/2' | 10 | 145 | 900 |

| AM-L2N2/059 | 0.558 | 14.74 | DN65/2.5° | 10 | 145 | 900 |

| AMz-L2N2/072 | 0.683 | 18.04 | 3' | 7 | 100 | 700 |

| AMz-L3V3/072 | 1.391 | 36.74 | DN65/3' | 10 | 145 | 700 |

| AMz-L3V3/080 | 1.548 | 40.89 | DN80/3.5' | 7 | 100 | 600 |

| AM-L3V3/0100 | 1.938 | 51.19 | DN100/4' | 7 | 100 | 600 |

| AMz-L3V3/0125 | 2.43 | 64.19 | DN1250/4.5" | 7 | 100 | 600 |

Materials of Construction

Pump Gearbox: Constructed from high-quality grey cast iron for durability and structural strength.

Pump Head: All product-contacting components are made from AISI 316L stainless steel, ensuring high corrosion resistance and hygienic safety.

Product-Wetted Elastomers: Available in EPDM, NBR, FPM—all compliant with FDA standards. PTFE is available for aggressive chemical applications.

Shaft Seal Options

Single Mechanical Seal or Single with Flush/Quench (steam barrier available for aseptic applications).

Double Mechanical Seal for flush-type sealing, suitable for high-purity or high-risk fluid transfer.

Standard Specification & Optional Features

Inlet and Outlet Connections: Available in a wide range of sanitary and industrial standards:

Threaded: BSP Male, DIN 11851, Rdg, SMS, ISS/DF, RJT, IAMD/3A, Triclamp, etc.

Flanged: BS 4504, DIN 2533, ASA/ANSI 150, BS10E, and others upon request.

Rotorcase Cover Options:

With integrated pressure relief valve for enhanced safety.

Heating/Cooling Jackets for rotorcase and cover (note: not available when relief valve is installed).

Rotor Types:

Bilobe rotors available in stainless steel or non-galling alloys for demanding applications.

Surface Finish Options:

Electropolished product-contact surfaces for enhanced cleanability and hygienic performance.

Complete Pump Unit Supply:

Includes pump, baseplate (carbon steel or stainless steel), coupling with guard, and geared electric motor compatible with:

Frequency inverter control

Manual variable speed drive

Please specify motor enclosure rating and electrical supply details when ordering.

Mechanical Seal Material Options

Carbon/Stainless Steel

Tungsten Carbide / Tungsten Carbide

Silicon Carbide / Silicon Carbide

Other combinations available depending on the fluid type and application requirements

Pump Sizing Guidelines

To accurately size a rotary lobe pump, it is essential to gather specific operational and fluid data. Providing the following information allows our application engineering or customer support team to recommend the optimal pump configuration for your process.

Product / Fluid Characteristics

Fluid name or product being pumped

Viscosity (in cP or mPa·s)

Specific Gravity (SG) or density (in kg/m³)

Operating temperature: minimum, normal, and maximum (°C)

CIP temperature: minimum, normal, and maximum (if applicable)

Performance Requirements

Flow rate: minimum, normal, and maximum (L/min or m³/h)

Discharge pressure/head: at the closest point to the pump outlet (bar or m)

Suction conditions: flooded suction, suction lift, NPSH available, etc.

Drive & Speed Control Options

Connection with reducer:

WR Series helical gear reducer (fixed speed)

WR Series helical gear + frequency-controlled motor (for variable speed control)

MBN Series manual variable speed drive

| AMz-L/0000 Horizontal type | |||||||||||||||||||

| D Indicate the size of the sanitary interface | |||||||||||||||||||

| S Indicate the width of the keyway | |||||||||||||||||||

| U Indicate the diameter of the pump foot hole | |||||||||||||||||||

| pump | A | B | C | D | E | F | G | H | I | J | K | L | M | N | P | Q | R | S | U |

| AMz-L1/025 | 96 | 123 | 229 | DN25/1' | 100 | 15 | 125 | 92 | 154 | 40 | 132 | 320 | 100 | 126 | 19 | 47 | 40 | 6 | 12 |

| AM-L1/035 | 96 | 123 | 229 | DN40V1.5' | 100 | 15 | 125 | 92 | 154 | 50 | 132 | 330 | 100 | 126 | 19 | 47 | 40 | 6 | 12 |

| AMz-L1/048 | 96 | 123 | 229 | DN50/2' | 100 | 15 | 125 | 92 | 154 | 64 | 132 | 343 | 100 | 126 | 19 | 47 | 40 | 6 | 12 |

| AMz-L2/035 | 108 | 150 | 275 | DN40V1.5' | 120 | 20 | 155 | 150 | 189 | 72 | 181 | 424 | 141 | 129 | 24 | 60 | 50 | 8 | 13 |

| AMz-L2/048 | 108 | 150 | 275 | DN502' | 120 | 20 | 155 | 150 | 189 | 79 | 181 | 424 | 141 | 129 | 24 | 60 | 50 | 8 | 13 |

| AMz-L2/059 | 108 | 150 | 275 | DN65/2.5' | 120 | 20 | 155 | 150 | 189 | 84 | 181 | 424 | 141 | 129 | 24 | 60 | 50 | 8 | 13 |

| AMz-L2/072 | 108 | 150 | 275 | 3' | 120 | 20 | 155 | 150 | 189 | 92 | 181 | 424 | 141 | 129 | 24 | 60 | 50 | 8 | 13 |

| AM-L3/072 | 164 | 212 | 399 | DN65/3° | 190 | 25 | 234 | 212 | 272 | 70 | 275 | 560 | 208 | 170 | 33 | B0 | 60 | 10 | 15 |

| AMz-L3/080 | 164 | 212 | 399 | DNBOV3.5' | 190 | 25 | 234 | 212 | 272 | 75 | 275 | 560 | 208 | 170 | 33 | B0 | 60 | 10 | 15 |

| AMz-L3/0100 | 164 | 212 | 399 | DN100V4" | 190 | 25 | 234 | 212 | 272 | 84 | 275 | 560 | 208 | 170 | 33 | 80 | 60 | 10 | 15 |

| AMz-L3/0125 | 164 | 212 | 399 | DN1250/4.5' | 190 | 25 | 234 | 212 | 272 | 97 | 275 | 560 | 208 | 170 | 33 | 80 | 60 | 10 | 15 |

| AMz-V/0000 Vertical type | ||||||||||||||||||

| D Indicate the size of the sanitary interface | ||||||||||||||||||

| S Indicate the width of the keyway | ||||||||||||||||||

| U Indicate the diameter of the pump foot hole | ||||||||||||||||||

| pump | A | B | C | D | E | F | G | H | J | K | L | M | N | P | Q | R | S | U |

| AMz-V1/025 | 96 | 143 | 239 | DN25/1' | 100 | 15 | 120 | 31 | 41 | 146 | 320 | 100 | 126 | 19 | 47 | 40 | 6 | 12 |

| AMz-V1/035 | 96 | 143 | 239 | DN40Y1.5' | 100 | 15 | 120 | 31 | 46 | 146 | 330 | 100 | 126 | 19 | 47 | 40 | 6 | 12 |

| AMz-V¹/048 | 96 | 143 | 239 | DN50/2' | 100 | 15 | 120 | 31 | 57 | 146 | 343 | 100 | 126 | 19 | 47 | 40 | 6 | 12 |

| AMz-V2/035 | 108 | 150 | 275 | DN40Y1.5' | 120 | 20 | 155 | 39 | 6B | 181 | 424 | 141 | 129 | 24 | 60 | 50 | 8 | 13 |

| AMz-V2/04B | 108 | 150 | 275 | DN50V2' | 120 | 20 | 155 | 39 | 75 | 181 | 424 | 141 | 129 | 24 | 60 | 50 | 8 | 13 |

| AMz-V2/059 | 108 | 150 | 275 | DN65/2.5' | 120 | 20 | 155 | 39 | 80 | 181 | 424 | 141 | 129 | 24 | 60 | 50 | 8 | 13 |

| AMz-V2/072 | 108 | 150 | 275 | 3' | 120 | 20 | 155 | 39 | 90 | 181 | 424 | 141 | 129 | 24 | 60 | 50 | 8 | 13 |

| AMz-V3/072 | 164 | 212 | 399 | DN65/3' | 190 | 25 | 234 | 60 | 85 | 275 | 560 | 208 | 170 | 33 | 80 | 60 | 10 | 15 |

| AMz-V3/080 | 164 | 212 | 399 | DNBOY3.5' | 190 | 25 | 234 | 60 | 88 | 275 | 560 | 208 | 170 | 33 | 80 | 60 | 10 | 15 |

| AMz-V3/0100 | 164 | 212 | 399 | DN100/4° | 190 | 25 | 234 | 60 | 97 | 275 | 580 | 208 | 170 | 33 | 80 | 60 | 10 | 15 |

| AMzV3/0125 | 164 | 212 | 399 | DN1250/4.5' | 190 | 25 | 234 | 60 | 100 | 275 | 560 | 208 | 170 | 33 | 80 | 60 | 10 | 15 |