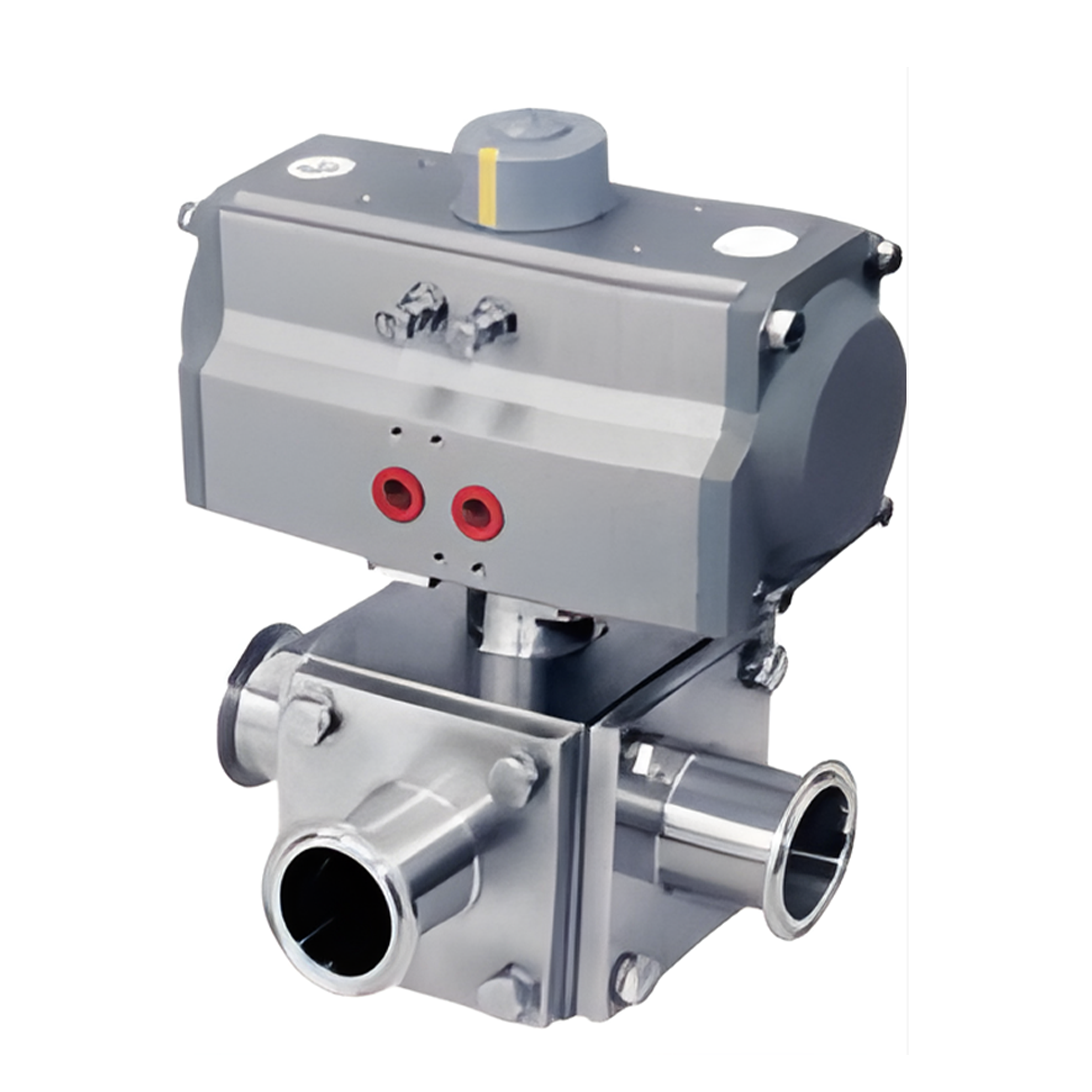

Rotary Dosing Valve

The Rotary Dosing Valve is a key component for precise and continuous discharge of powders and granules. By rotating its vanes, the valve ensures steady, metered feeding with excellent airlock performance, making it ideal for both positive and negative pressure pneumatic conveying systems. Its compact structure, easy operation, and quick-release design make it widely used in food, pharmaceutical, dairy, and chemical industries for weighing, dosing, and transfer applications.

- Overview

- Recommended Products

- Continuous and metered discharge for precise material handling

- Excellent sealing performance, ideal for airlock applications in pneumatic systems

- Durable construction suitable for frequent-duty operations

- Quick-assembly design for easy maintenance and hygienic compliance

- Available in various material grades to handle corrosive or high-purity substances

- Highly versatile, compatible with hoppers, screw conveyors, weighing systems, and automatic packaging lines

- Standard: 0–180° actuator

- Optional: 0–90° actuator, pneumatic rotary motor, servo motor

- Contact parts: SS304, SS316L

- Non-contact parts: SS304

- Ra < 0.4 μm (wetted surfaces)

- Ra < 0.8 μm (non-wetted surfaces)

- DIN 11850 Series 2

- ASME-BPE

- ISO 1127 Series 1

Detailed Description

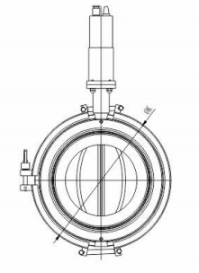

The Rotary Dosing Valve, also known as a Rotary Valve, Ball-Type Rotary Valve, or Rotary Airlock Feeder, is a specialized device designed for the controlled, continuous, and dust-free discharge of bulk solids, such as powders and granules. As material falls by gravity from the upper hopper, it fills the spaces between the rotating vanes. As the rotor turns or reciprocates, the valve discharges the material at a steady, metered rate from the bottom outlet.

In pneumatic conveying systems, whether under positive or negative pressure, the rotary valve ensures a consistent feed into the conveying line while maintaining an effective airlock. This prevents air leakage or backflow, stabilizes pressure inside the pipeline, and keeps the bulk material transport process smooth and uninterrupted.

Featuring a robust structure, stable performance, and quick-release clamp design, this valve is easy to disassemble and clean, making it ideal for industries with high hygiene requirements such as food processing, pharmaceuticals, infant formula, sugar refining, and fine chemicals.

Key Benefits:

Parameter

Specifications:

Size range: 3.0" – 100"

Working pressure: -0.1 MPa ~ +0.5 MPa

Control air supply pressure: 0.4 – 0.8 MPa

Actuator options:

Working temperature: -20°C ~ +150°C (depending on sealing material)

Metal materials:

Sealing material: Viton (standard, compliant with FDA 21 CFR 177.2660), EPDM, Silicone (optional)

Surface finish:

Airtight pressure: Non-airtight (standard configuration)

Sterilization method: SIP (Steam-in-Place)

Explosion-proof rating: ATEX II 2 GD T4

Connection standards:

Connection types: Clamped, welded

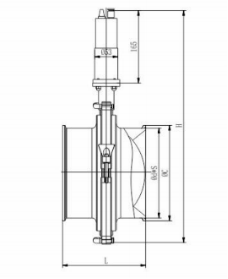

| DIN | NPS | H | L | K | C | DIN11850 | ASTM-BPE | ISO 1127 | BS 4825 | GB/T 17395 |

| series 2 | series 1 | |||||||||

| Φdxs | Φdxs | Φdxs | Φdxs | Φdxs | ||||||

| DN50 | 2.0" | 350 | 100 | 130 | 64 | 53×1.5 | 50.8×1.65 | 48.3×2 | 50.8×1.6 | 57×1.5 |

| DN65 | 2.5" | 361 | 100 | 130 | 77.5/91 | 70×2 | 63.5×1.65 | 60.3×2 | 63.5×1.6 | 76×2 |

| DN80 | 3.0" | 361 | 100 | 160 | 106 | 85×2 | 76.2×1.65 | 88.9×2.6 | 76.2×1.6 | 89×2 |

| DN100 | 4.0" | 382 | 100 | 188 | 119 | 104×2 | 101.6×2.11 | 114.3×2.6 | 101.6×2 | 108×2 |

| DN125 | 5.0" | 446 | 130 | 235 | 155 | 129×2 | 127×2.11 | 139.7×2.6 | 114.3×2 | 133×2 |

| DN150 | 6.0" | 446 | 130 | 235 | 166.8 | 154×2 | 152.4×2.77 | 168.3×2.6 | 168.3×2.6 | 159×2 |

| DN200 | 8.0" | 520 | 180 | 295 | 217.7 | 204×2 | 203.2×2.77 | 219.1×2.6 | 219.3×2.6 | 219×2 |

| DN250 | 10.0" | 563 | 200 | 336 | 268.5 | 254×2 | 254×2.77 | 273×2.9 | / | 273×2 |

| DN300 | 12.0” | 613 | 200 | 386 | 319.3 | 304×2 | 304.8×3.4 | 323.8×2.9 | / | 324×2 |