angle seat valve

The JZ5 Series Pneumatic Angle Seat Valve is a high-performance, pneumatically actuated valve designed for efficient flow control in demanding industrial and hygienic applications. With a robust Y-pattern body and compact actuator design, the valve ensures up to 30% higher flow rates compared to conventional globe valves, while maintaining smooth, low-turbulence operation. It is widely used in steam systems, sterilization equipment, food and beverage processing, chemical industries, and automated production lines. The JZ5 valve offers a reliable, durable, and hygienic solution for high-temperature and high-pressure environments.

- Overview

- Recommended Products

- Enhanced flow efficiency

- Fast actuation and reliable sealing

- Long service life under continuous operation

- Ideal performance in high-temperature and steam environments

- Available in a range of sizes, materials, and connection types, the JZ5 series is a versatile, maintenance-friendly, and cost-effective solution for hygienic and industrial flow control applications.

Detailed Description

JZ5 Series Pneumatic Angle Seat Valve – High-Performance Flow Control for Steam and Process Applications

The JZ5 Series Angle Seat Valve is a pneumatically operated control valve designed for high-efficiency flow regulation in demanding applications. Widely used in food processing, chemical production, sterilizers, autoclaves, dry-cleaning machines, industrial dryers, and breweries, this valve is particularly well-suited for steam pipeline systems and automated process lines that require reliable and hygienic control.

While its working principle is similar to that of a traditional globe valve, the JZ5 features an optimized Y-body configuration paired with a compact pneumatic actuator. This advanced design significantly increases the flow passage cross-section, allowing for up to 30% greater flow capacity and ensuring smoother fluid dynamics with reduced turbulence and pressure drop.

Moreover, the change in media flow direction within the Y-pattern body enables the use of smaller actuators, reducing the valve’s overall footprint and energy consumption, while maintaining fast and responsive operation.

The JZ5 Angle Seat Valve delivers:

Technical data

| Material | Contact product parts | 316L(1.4404) |

| non-contact product parts | 304(1.4301) | |

| Provide EN 102043.1B certificate | ||

| Seal material | Standard | PTFE |

| Option | FPM,Silicone,EPDM | |

| All seal materials comply with FDA 177.2600 | ||

| Temperature | working temperature | -50~+180℃(PTFE) |

| Pressure | product pressure | 0-16bar |

| Control air pressure | 5~8bar | |

| Surface treatment | Internal surface | Ra≤0.8μm |

| External surface | Matte | |

| Connection | Connection method:welding、thread、clamp、flange | |

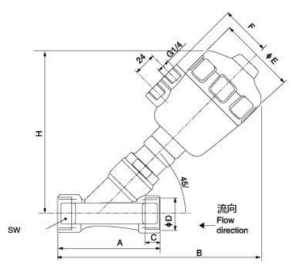

| dimensions(mm) | |||||||||

| Size | Bore | Actuator | A | B | C | E | F | H | SW |

| φD | (mm) | (mm) | |||||||

| G1/2 | 13 | 50 | 85 | 173 | 12 | 64 | 44 | 137 | 27 |

| G34 | 20 | 50 | 95 | 178 | 12 | 64 | 44 | 145 | 32 |

| G1 | 25 | 63 | 105 | 212 | 14 | 80 | 52 | 173 | 41 |

| G1-1/4 | 32 | 63 | 120 | 255 | 16 | 101 | 60 | 210 | 50 |

| G1-1/2 | 40 | 63 | 130 | 301 | 18 | 127 | 73 | 280 | 55 |

| G2 | 50 | B0 | 150 | 346 | 20 | 153 | B6 | 301 | 70 |

| G2-1/2 | 65 | 80 | 185 | 372 | 22 | 153 | 86 | 315 | 70 |

| dimensions(mm) | |||||||

| Size | Bore | KV | Working pressure | Control air pressure | Actuator | Flow | NC/NO |

| (mm) | [m3h] | [bar] | bar | (mm) | |||

| G3/8 | 13 | 3.7 | 0-16 | 4 | 40 | Up the seat |  |

| G1/2 | 13 | 4.2 | 0-16 | 2.7 | 50 | Up the seat | |

| G3/4 | 20 | 8 | 0-16 | 2.7 | 50 | Up the seat | |

| G1 | 25 | 19 | 0-16 | 2 | 63 | Up the seat | |

| G11/4 | 32 | 27.5 | 0-16 | 2 | 63 | Up the seat | |

| G11/2 | 40 | 42 | 0-16 | 2 | 63 | Up the seat | |

| G2 | 50 | 52 | 0-16 | 2 | 63 | UD the seat | |

| G21/2 | 65 | 77 | 0-14 | 1.6 | 80 | Up the seat | |