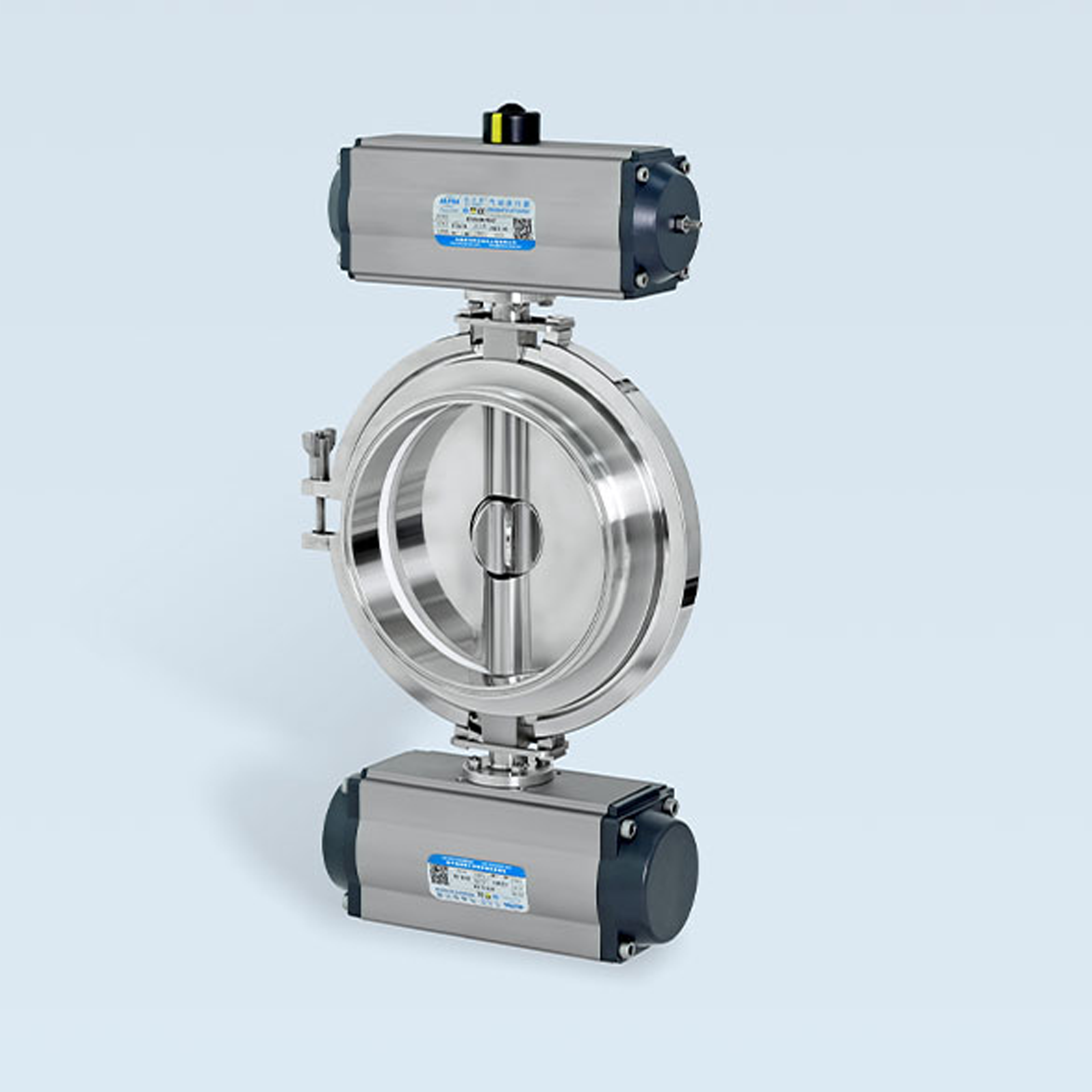

Split Butterfly Valve

SBV Split Butterfly Valve – Contained Powder Transfer by AVM FLUID

AVM FLUID’s SBV Split Butterfly Valve is a high-containment valve system engineered for the safe transfer of highly potent APIs (HPAPI) and toxic powders. Designed to meet stringent containment requirements (up to OEB5, <1μg/m³), the system ensures zero contact between product and environment through the synchronized opening of the active and passive halves.

Built on a robust platform, it offers exceptional docking tolerance (±14 mm) and intuitive operation. Ideal for pharmaceutical, biotech, and fine chemical industries, it supports full CIP/SIP cleaning and complies with GMP and FDA standards.

- Overview

- Recommended Products

- •Ensure full compliance with industry regulatory standards.

- •Enable safe handling of high-potency active pharmaceutical ingredients (HPAPI), protecting personnel and minimizing environmental contamination.

- •Significantly reduce the risk of cross-contamination.

- •Meet GMP compliance and strict product quality requirements.

- •Maximize transfer efficiency for poorly flowing or high-value materials.

- •Eliminate the need for costly, bulky secondary containment systems and high-class cleanroom environments.

- ◆ Compliant with GMP standards

- ◆ Materials meet FDA requirements

- ◆ Conforms to European ATEX directive for hazardous areas

- ◆ Compliant with European Pressure Equipment Directive (PED)

- ◆ Meets European Machinery Directive

- ◆ Manufactured under ISO 9001 certified facilities

- ◆ Full material certification and batch traceability

- ◆ Independently validated according to sealing performance measurement guidelines (ISPE SMEPAC)

- ◆ Convenient and effective GMP-compliant cleaning design

- ◆ Suitable for cleaning inside high-pressure sterilization vessels

- ◆ In-place cleaning of exposed surfaces of the main valve

- ◆ Cleaning of passive valves and connected vessels

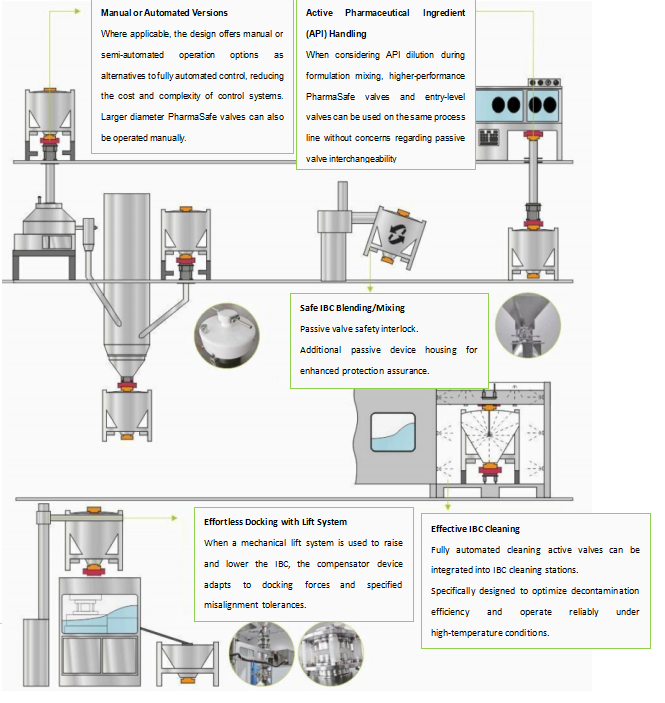

- ◆ Fully automated or semi-automated versions available to meet application requirements;

- ◆ Status information and program interlock functions guaranteed through pneumatic or electric proximity sensors;

- ◆ Fully integrated and factory-tested control system;

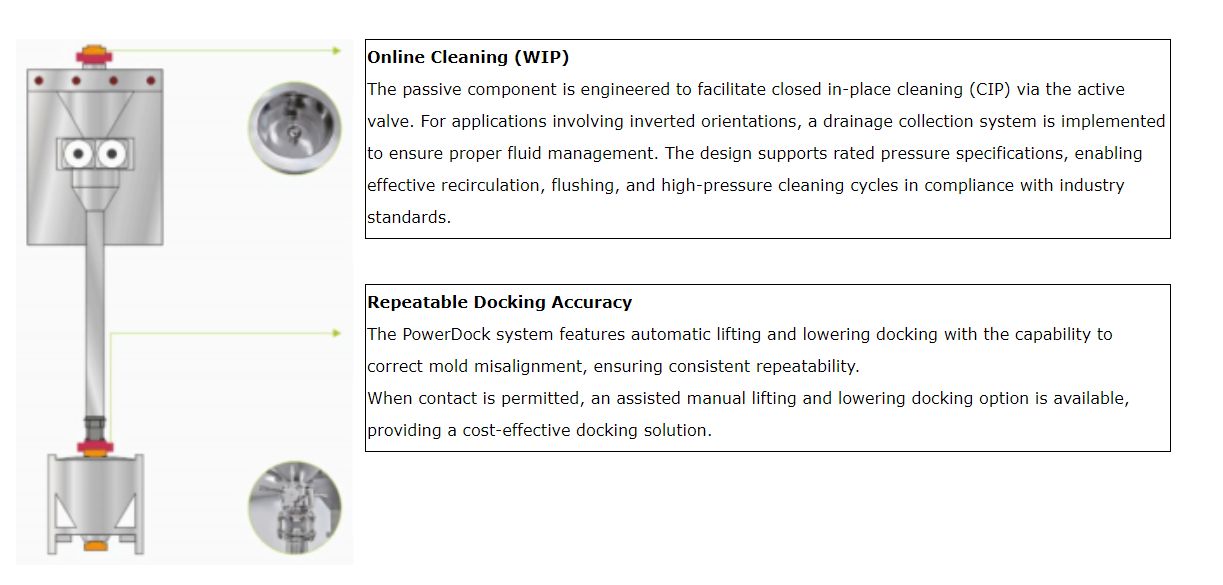

- ◆ Repeatable and safe alignment with devices connected to hoists and docking systems;

- ◆ Lightweight versions available;

- ◆ GMP-compliant covers to protect valves when not in use.

Detailed Description

AVM FLUID SBV Split Butterfly Valve – High-Containment Powder Transfer Made Smarter

At AVM (AOMI) FLUID, we specialize in high-containment transfer systems for potent active pharmaceutical ingredients (HPAPI) and toxic media. Our advanced SBV Split Butterfly Valve system is engineered to ensure the safest and most efficient powder handling in critical applications across the pharmaceutical, biotech, and chemical industries.

Unlike traditional valve systems, the AVM SBV offers superior docking flexibility with a floating active flange that allows for a generous misalignment tolerance of up to ±14 mm. This feature significantly enhances operational efficiency and minimizes production downtime.

The SBV system ensures complete containment by synchronously opening the active and passive halves of the valve, eliminating the risk of product contamination or operator exposure. With verified containment performance levels reaching <1μg/m³ (OEB5), our SBV valve supports full compliance with GMP, FDA, and cGMP regulations.

Additional advantages include:

Robust, compact design for repeated use in demanding environments

Tool-free assembly and disassembly for easy cleaning and maintenance

Compatibility with CIP/SIP systems, ensuring hygienic processing

Ideal for integration into isolators, RTP systems, and aseptic transfer lines

Choose AVM FLUID’s SBV Split Butterfly Valve for cutting-edge containment technology, intuitive operation, and maximum product and operator protection—all tailored to the highest global standards.

Parameter

| Technology | Ingredients | Materials | |

| Ingredient | Mixed | HPAPI | Powder |

| Container loading | Grind | Reagent | Semisolid |

| Filtration | Sieving | Intermediate | Particle |

| Centrifugal separation | Compress | Accessory | Suspension |

| Desiccation | Filing | Formula mixing | Tablets/capsules |

| Sampling | Coating | Raw material | liquid |

| Granulation | |||

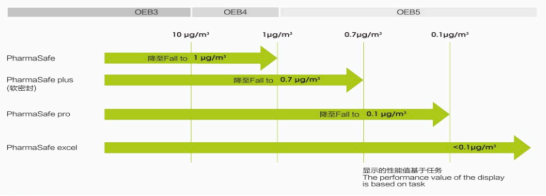

Sealing Performance

The valve's containment performance is independently verified by the customer and third-party organizations in accordance with the ISPE SMEPAC (Standardized Measurement of Equipment Particulate Airborne Contamination) guideline.

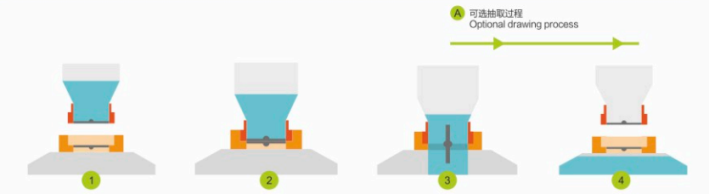

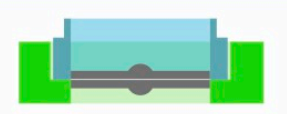

Operation Sequence

Reduced to as low as 1 µg/m³ (OEB4 level)

High containment performance without the need for additional seals, vacuum, or extraction systems.

Entry-level design offers a simple and cost-effective upgrade path to help meet essential GMP and containment requirements in manufacturing processes.

Minimal component design ensures easy operation, cleaning, and maintenance, while delivering top-tier performance for an entry-level solution.

Reduced to as low as 0.7 µg/m³ (OEB5 level)

The use of soft sealing allows for a tighter fit between the valve discs, effectively preventing leakage issues caused by deformation due to metal fatigue after prolonged use.

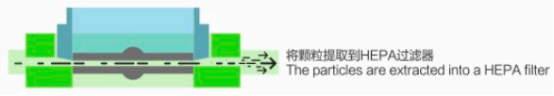

Reduced to as low as 0.1 µg/m³ (OEB5 level)

Achieve rapid cleanliness performance through simple and quick extraction.

By using a recovery process integrated with the valve, it effectively prevents air contamination after valve separation.

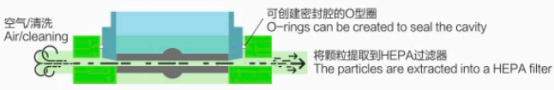

﹤0.1 µg/m³ (OEB5 level)

This compact and efficient split-type valve delivers advanced performance at the nanogram level.

It features a sequence that enables simultaneous cleaning and extraction.

During the separation process, a sealed cavity is formed between the active and passive interfaces, allowing cleaning and extraction to occur concurrently. This effectively eliminates airborne particles that could cause contamination after the valve is fully disassembled.

Characteristics and advantages

| Optimal sea design | Seats are manufactured within precise tolerances to ensure maximum performance: |

| ◆Repeatable performance in the equipment life cycle. | |

| ◆Ensure that the seat of active valve and passive valve can be replaced with each other. | |

| ◆Easy manual operation even when the valve diameter is larger. | |

| ◆Replacement seat size consistency. | |

| Diverse valve plate structure | Provide better choices |

| ◆We offer two mainstream valve plate structures for to customers choose from | |

| ◆Metal surface seal | |

| ◆Simple structure can meet the production needs,and easy maintenance,lower cost | |

| ◆Soft seal between metals | |

| ◆Solve the problem of micro-leakage between valve plates caused by various factors after long-term use of the valve | |

| Monomer design | One-piece rugged design with minimal parts: |

| ◆Easier maintenance; | |

| ◆Metal to metal seal of valve disc; | |

| ◆Passive seat can be removed in a few seconds. | |

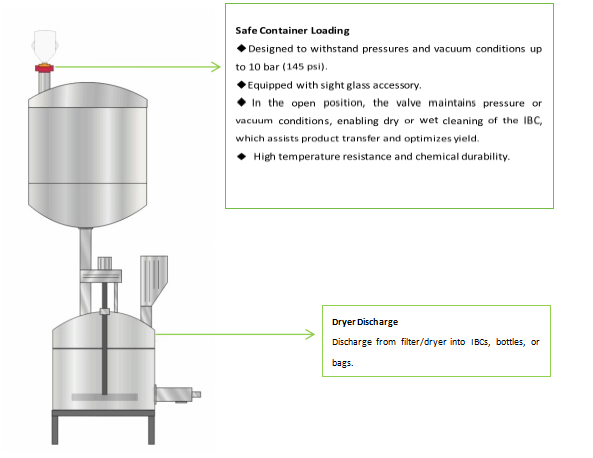

| Safe pressure rating/vacuum design | Unique way to achieve pressure seal: |

| ◆Powder conveying can be achieved with the help of pressure or vacuum; | |

| ◆The driving disc can maintain a thin thickness to maximize flow,while minimizing friction and indirect wear between the small disc and the seat; | |

| ◆The design enables easy manual operation even if the valve diameter is larger. | |

| Safety lock structure | Ensure process and personnel safety: |

| ◆ Does not accidentally open active and passive devices without docking them together. | |

| ◆When this valve is open,the passive device cannot be removed from the active device. | |

| ◆Additional automatic security interlocks can be provided | |

| Process diversity | Can be used for muiltiple process functions: |

| ◆Product feeding/batching; | |

| ◆WIP/CIP; | |

| ◆ Sampling; | |

| ◆Process inspection(sight glass) | |

| Small fotprint | Asmall footprint is maintained throughout the size range,eliminating the need to manually operate this valve using an extension handle. |

Compliance and Quality Assurance

| Specification | ||||||||

| PS50 | PS100 | PS150 | PS200 | PS250 | PS300 | |||

| Dropto1μg/m³ | 一 | |||||||

| Drop to0.7μg/m³ | 一 | - | - | |||||

| Drop to0.1μg/m² | 一 | 一 | 一 | 一 | - | |||

| <0.1μg/m³ | - | 一 | - | 一 | - | 一 | ||

| Size | DN50 | DN100 | DN150 | DN200 | DN250 | DN300 | ||

| (2") | (4") | (6") | (8") | (10") | (12") | |||

| *Rated pressure* | 2Bar | 1Bar | No | |||||

| *Rated vacuum* | ||||||||

| Full vacuum | ||||||||

| Controls | Manual operation | - | 一 | - | ||||

| Semi-automatic | 一 | 一 | 一 | |||||

| Semi-automatic | 一 | 一 | 一 | 一 | 一 | |||

| Product contact | Main | 316L | - | 一 | - | - | - | - |

| surface material | body | Aloy22 | 一 | 一 | - | |||

| POM | 一 | 一 | - | - | - | |||

| Sealing | EPDM | 一 | 一 | - | 一 | 一 | ||

| element | FKM | 一 | - | 一 | 一 | |||

| FFKM | 一 | 一 | 一 | 一 | 一 | - | ||

| Connecting | Three clip type | 一 | - | 一 | 一 | |||

| interface | PN6/10/16 | 一 | 一 | - | 一 | 一 | 一 | |

| ANSI | 一 | 一 | 一 | 一 | ||||

| Other | Available with process/container | |||||||

| Rated pressure/vacuum only when used in conjunction with applicable rated pressure/vacuum components or accessories. | ||||||||

Cleaning and Sanitization

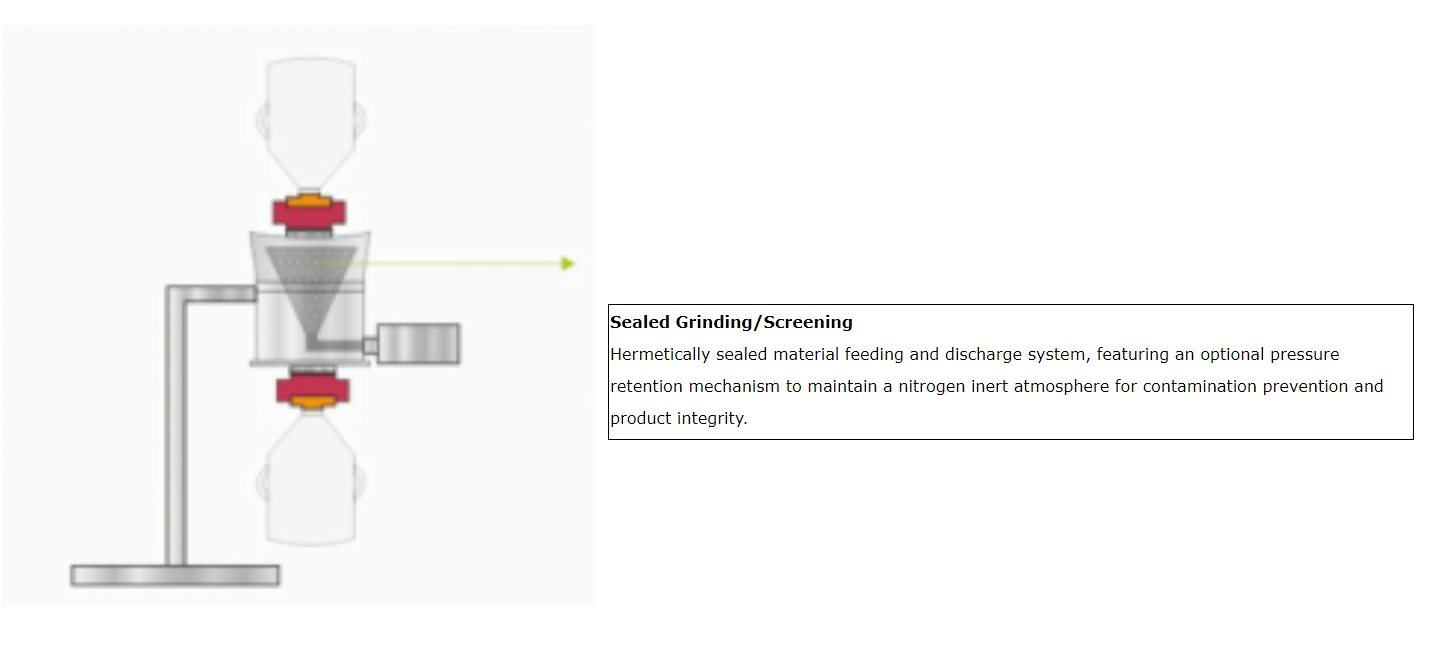

Using our specially designed Online Cleaning (WIP) system, efficient cleaning and sanitization of product contact surfaces and sealing areas are ensured.

Handling and Automation

The system ensures safe operation in hazardous or inaccessible areas, or where production scale prohibits manual handling: