Sanitary centrifugal pump

The AMH series centrifugal pump is designed for high efficiency, sanitary performance, and economic value. Engineered to meet the demanding requirements of industries such as food processing, beverages, dairy, pharmaceuticals, and chemicals, the AMH pump ensures gentle product handling with excellent corrosion resistance. Its hygienic construction supports CIP (Clean-in-Place) cleaning and complies with modern sanitary standards. With nine size options available, the AMH pump series offers flexible solutions for a wide range of fluid transfer applications, making it an ideal choice for both sanitary and industrial environments.

- Overview

- Recommended Products

Detailed Description

AMH Series Centrifugal Pump – High Efficiency and Hygienic Design

The AMH pump is a high-performance and cost-effective centrifugal pump designed to meet the stringent requirements of hygienic applications while providing gentle product handling and excellent chemical resistance. The AMH series is available in nine different sizes: AMH-5, -10, -15, -20, -25, -30, -35, -40, and -45, offering versatile options to suit various process demands.

Standard Design

Each AMH pump is composed of a standard electric motor, pump shaft, flexible coupling (AMH-5 uses a wedge bolt), adapter, backplate, impeller, pump casing, and mechanical seal. All models are fully compatible with CIP (Clean-In-Place) systems, featuring hygienic design principles with large-radius transitions and cleanable seals to ensure optimal sanitation.

For hygienic applications, AMH pumps are equipped with a durable stainless steel motor cover that protects the motor and supports sanitary operations. Every complete AMH unit includes four adjustable stainless steel support legs for stable and flexible installation.

For industrial (non-hygienic) applications, AMH pumps are available without the stainless steel motor cover, offering a more economical solution while maintaining robust performance.

Parameter

Shaft Seal

The AMH pump is equipped with an external single mechanical seal or a water-flushed mechanical seal. The stationary seal ring is made of AISI 316L stainless steel combined with either silicon carbide or tungsten carbide, while the rotating seal ring is typically constructed from high-grade carbon (graphite). For water-flushed configurations, a durable lip seal is also included to enhance long-term performance. Additionally, the AMH pump can be optionally fitted with a double mechanical seal to meet more demanding process requirements, ensuring reliable operation under a wide range of sanitary and industrial conditions.

| Technical data | |

| Max.inlet pressure | 4 bar |

| Maximum export pressure | 6.5 bar |

| Temperature range | -20℃~+135℃(EPDM) |

| Noise level(at 1m) | 60-85 dB(A) |

Flushed Shaft Seal (AMH-5 to AMH-45):

Maximum water pressure inlet: 1 bar

Water consumption: 0.25 - 0.5 L/min

Double Mechanical Shaft Seal:

Maximum water pressure inlet (AMH-5 to AMH-45): 500 kPa (5 bar)

Water consumption: 0.25 - 0.5 L/min

Connections for FSS and DMSS:

R 1/8" (BSP) external thread

Motor:

Foot-flanged motor according to IEC metric standard

2 poles = 3000 rpm at 50 Hz

IP55 protection

Insulation class F

Voltage and Frequency:

3-phase, 50 Hz, 220-240 V Δ / 380-420 V Y for ≤ 4 kW

3-phase, 50 Hz, 380-420 V Δ / 660-690 V Y for ≥ 5.5 kW

Motor Sizes:

50 Hz: 0.75, 1.1, 1.5, 2.2, 3, 4, 5.5, 7.5, 11, 15, 18.5, 22 kW

Ordering Information:

Please specify the following when placing an order:

Pump type

Voltage and frequency

Connection types

Flow rate, pressure, and temperature

Density and viscosity of the product

Additional options

| Connections(mm)Sanitary version | ||||||

| ISO | ISO | DIN | SMS | BS | DS | |

| Clamp | Male | Male | Male | Male | Male | |

| D151 | 21 | 21 | 22 | 20 | 27 | 20 |

| D238 | 21 | 21 | 22 | 20 | 27 | 20 |

| D163 | 21 | 21 | 25 | 24 | 27 | 24 |

| D251 | 21 | 21 | 22 | 20 | 27 | 20 |

| D176 | 21 | 21 | 30 | 24 | 27 | 24 |

| D263 | 21 | 21 | 25 | 24 | 27 | 24 |

| D1 101.6 | 21 | 21 | 30 | 35 | 32 | |

| D276 | 21 | 21 | 30 | 20 | 27 | |

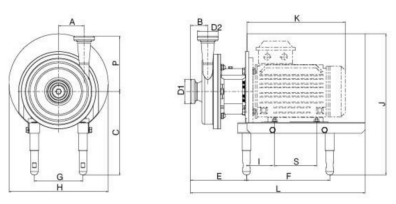

| Size | 0.75/1.1kW | 1.5kW | 2.2kW |

| A | 80 | 80 | 80 |

| B | 53 | 53 | 53 |

| C Min | 202 | 192 | 192 |

| C Max | 257 | 247 | 247 |

| E | 125 | 127 | 127 |

| F | 190 | 240 | 240 |

| G | 125 | 140 | 140 |

| H | 251 | 288 | 288 |

| I | 82 | 82 | 82 |

| J Min | 322 | 342 | 342 |

| J Max | 377 | 397 | 397 |

| K | 245 | 260 | 285 |

| P | 160 | 160 | 160 |

| S | 100 | 100 | 125 |

| L | 511 | 538 | 538 |

AMH-5

| Size | 1.5kW | 2.2kW | 3kW | 4kW |

| A | 80 | 80 | 80 | 90 |

| B | 53 | 53 | 53 | 50 |

| C Min | 192 | 192 | 222 | 214 |

| C Max | 247 | 247 | 277 | 269 |

| E | 127 | 127 | 137 | 137 |

| F | 240 | 240 | 300 | 300 |

| G | 140 | 140 | 160 | 190 |

| H | 288 | 288 | 323 | 359 |

| I | 82 | 82 | 95 | 102 |

| J Min | 342 | 342 | 392 | 397 |

| J Max | 397 | 397 | 447 | 452 |

| K | 260 | 285 | 320 | 335 |

| P | 160 | 160 | 160 | 185 |

| S | 100 | 125 | 140 | 140 |

| L | 538 | 538 | 538 | 548 |

AMH-10

| Size | 3kW | 4kW | 5.5kW |

| A | 80 | 90 | 90 |

| B | 53 | 50 | 53 |

| C Min | 222 | 214 | 244 |

| C Max | 277 | 269 | 299 |

| E | 137 | 137 | 157 |

| F | 300 | 300 | 381 |

| G | 160 | 190 | 216 |

| H | 323 | 359 | 383 |

| I | 95 | 102 | 135 |

| J Min | 392 | 397 | 412 |

| J Max | 447 | 452 | 467 |

| K | 320 | 335 | 285 |

| P | 160 | 185 | 185 |

| S | 140 | 140 | 140 |

| L | 538 | 548 | 568 |

AMH-15

| Size | 2.2kW | 3kW | 4kW | 5.5/7.5kW |

| A | 80 | 80 | 90 | 90 |

| B | 53 | 53 | 50 | 50 |

| C Min | 192 | 222 | 214 | 244 |

| C Max | 247 | 277 | 269 | 299 |

| E | 127 | 137 | 137 | 157 |

| F | 240 | 300 | 300 | 381 |

| G | 140 | 160 | 190 | 316 |

| H | 288 | 323 | 359 | 383 |

| I | 82 | 95 | 102 | 135 |

| J Min | 342 | 392 | 397 | 447 |

| J Max | 397 | 447 | 452 | 502 |

| K | 285 | 320 | 335 | 402 |

| P | 160 | 160 | 185 | 185 |

| S | 125 | 140 | 140 | 140 |

| L | 538 | 538 | 548 | 568 |

AMH-20

| Size | 5.5/7.5kW | 11/15kW |

| A | 90 | 126 |

| B | 50 | 107 |

| C Min | 244 | 228 |

| C Max | 299 | 345 |

| E | 157 | 192 |

| F | 381 | 483 |

| G | 316 | 254 |

| H | 383 | 485 |

| I | 135 | 253 |

| J Min | 447 | 438 |

| J Max | 502 | 554 |

| K | 402 | 493 |

| P | 185 | 204 |

| S | 140 | 210 |

| L | 568 | 775 |

AMH-25

| Size | 4kW | 5.5/7.5kW | 11/15kW |

| A | 90 | 90 | 126 |

| B | 50 | 50 | 107 |

| C Min | 214 | 244 | 228 |

| C Max | 269 | 299 | 345 |

| E | 137 | 157 | 192 |

| F | 300 | 381 | 483 |

| G | 190 | 316 | 254 |

| H | 359 | 383 | 485 |

| I | 102 | 135 | 253 |

| J Min | 397 | 447 | 438 |

| J Max | 452 | 502 | 554 |

| K | 335 | 402 | 493 |

| P | 185 | 185 | 204 |

| S | 140 | 140 | 210 |

| L | 548 | 568 | 775 |

AMH-30

| Size | 7.5kW | 11/15kW |

| A | 90 | 126 |

| B | 50 | 107 |

| C Min | 244 | 228 |

| C Max | 299 | 345 |

| E | 157 | 192 |

| F | 381 | 483 |

| G | 316 | 254 |

| H | 383 | 485 |

| I | 135 | 253 |

| J Min | 447 | 438 |

| J Max | 502 | 554 |

| K | 402 | 493 |

| P | 185 | 204 |

| S | 140 | 210 |

| L | 568 | 775 |

AMH-35

| Size | 7.5kW | 11/15kW | 18kW |

| A | 90 | 126 | 126 |

| B | 50 | 50 | 107 |

| C Min | 244 | 244 | 228 |

| C Max | 299 | 299 | 345 |

| E | 157 | 148 | 192 |

| F | 381 | 381 | 483 |

| G | 316 | 216 | 254 |

| H | 383 | 383 | 485 |

| I | 135 | 135 | 253 |

| J Min | 447 | 447 | 438 |

| J Max | 502 | 502 | 554 |

| K | 402 | 402 | 493 |

| P | 185 | 231 | 231 |

| S | 140 | 140 | 210 |

| L | 568 | 568 | 775 |

AMH-40

| Size | 7.5kW | 11/15/18.5kW | 22kW |

| A | 90 | 126 | 126 |

| B | 50 | 50 | 107 |

| C Min | 214 | 244 | 260 |

| C Max | 269 | 299 | 365 |

| E | 137 | 148 | 192 |

| F | 300 | 381 | 506 |

| G | 216 | 254 | 279 |

| H | 359 | 383 | 533 |

| I | 102 | 135 | 174 |

| J Min | 397 | 447 | 484 |

| J Max | 452 | 502 | 589 |

| K | 335 | 402 | 570 |

| P | 185 | 231 | 231 |

| S | 140 | 140 | 241 |

| L | 568 | 568 | 865 |