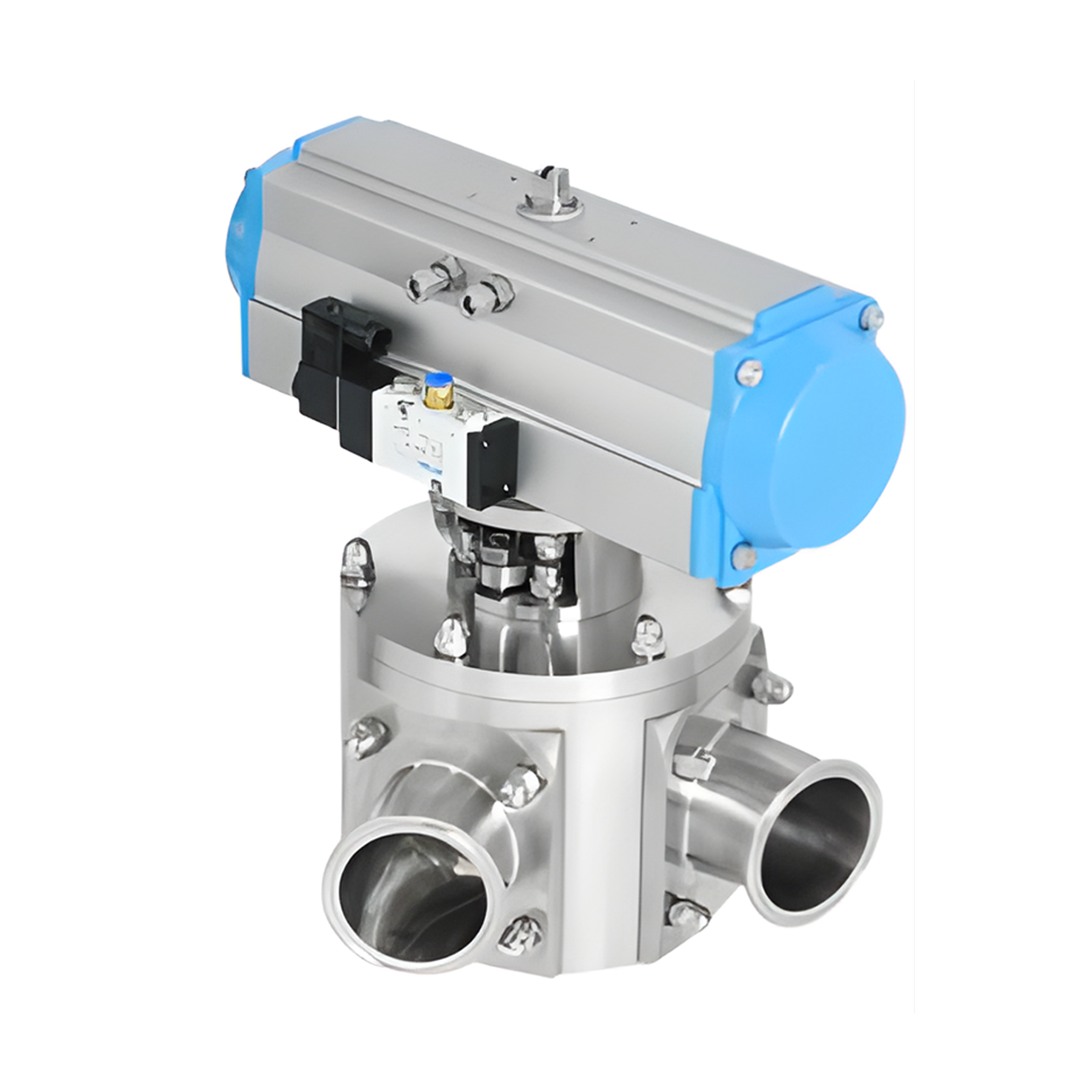

Pressure reducing valve

The pressure reducing valve is available in two configurations: T-type and L-type, with a pressure differential range from 0.5 bar to 8 bar, and a maximum operating pressure of 10 bar.

Our design strictly complies with 3-A Sanitary Standard 64-00 (USA), ensuring a dead-leg-free and residue-free structure. The valve also features an optimized Kv value curve, offering stable and accurate pressure regulation performance. This makes it ideal for hygienic applications in industries such as dairy, beverage, food processing, and pharmaceuticals.

- Overview

- Recommended Products

- Standard: Ra < 0.6 μm

- Mechanical Polish (MP): Ra < 0.3 μm

- Electropolish (EP): Ra < 0.3 μm

Detailed Description

Sanitary pressure reducing valves are specifically engineered for hygienic and aseptic processing applications in industries such as dairy, beverage, brewery, pharmaceutical, and food processing. Designed in strict compliance with the 3-A Sanitary Standard 64-00, these valves feature a dead-leg-free, crevice-free internal design that prevents product retention and microbial contamination. Available in T-type and L-type configurations, they accommodate pressure differentials ranging from 0.5 to 8 bar, with a maximum operating pressure of 10 bar. The valve body is polished to a sanitary finish (Ra ≤ 0.6 μm) and made from AISI 316L stainless steel, ensuring corrosion resistance and ease of cleaning. Equipped with FDA-compliant seals such as EPDM, FPM, or silicone, the valve delivers precise, stable pressure control with a high flow coefficient (Kv) and smooth flow characteristics. Compact and modular, it supports various connection types including clamp, weld, and threaded fittings, conforming to international standards like DIN, SMS, ISO, and 3A. This pressure reducing valve is ideal for maintaining consistent downstream pressure in processes including pasteurization, filtration, fermentation, and filling lines, and is compatible with Clean-in-Place (CIP) and Steam-in-Place (SIP) procedures to ensure optimal hygiene and performance.

Technical Features

Specifications: 1/2" to 3" (DN10 to DN65)

Material: 316L / 1.4404, ASME BPE 316L / 1.4435, NB2 Fe ≤ 0.5%

Pressure: Up to 10 bar (1.0 MPa)

Temperature Range: -20℃ to +150℃ (depending on seal material)

Sealing Materials: EPDM, FKM, HNBR, PTFE

Connection Standards: DIN, SMS, ISO, IDF, RJT, BS4825, ASME BPE, 3A, DIN11864, DIN11853

Connection Methods: Threaded, Clamp, Welding, Flanged

Surface Finish:

Certifications: FDA 177.2600, 3A-64-00, Glass II USP, Glass VI Chapter 88, GB4806.11, EU Regulation (EC) No 1935/2004, PED 97/23/EC

Pressure reducing valve flow graph

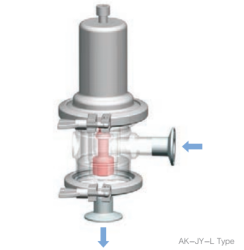

L type pressure reducing valve

T type pressure reducing valve