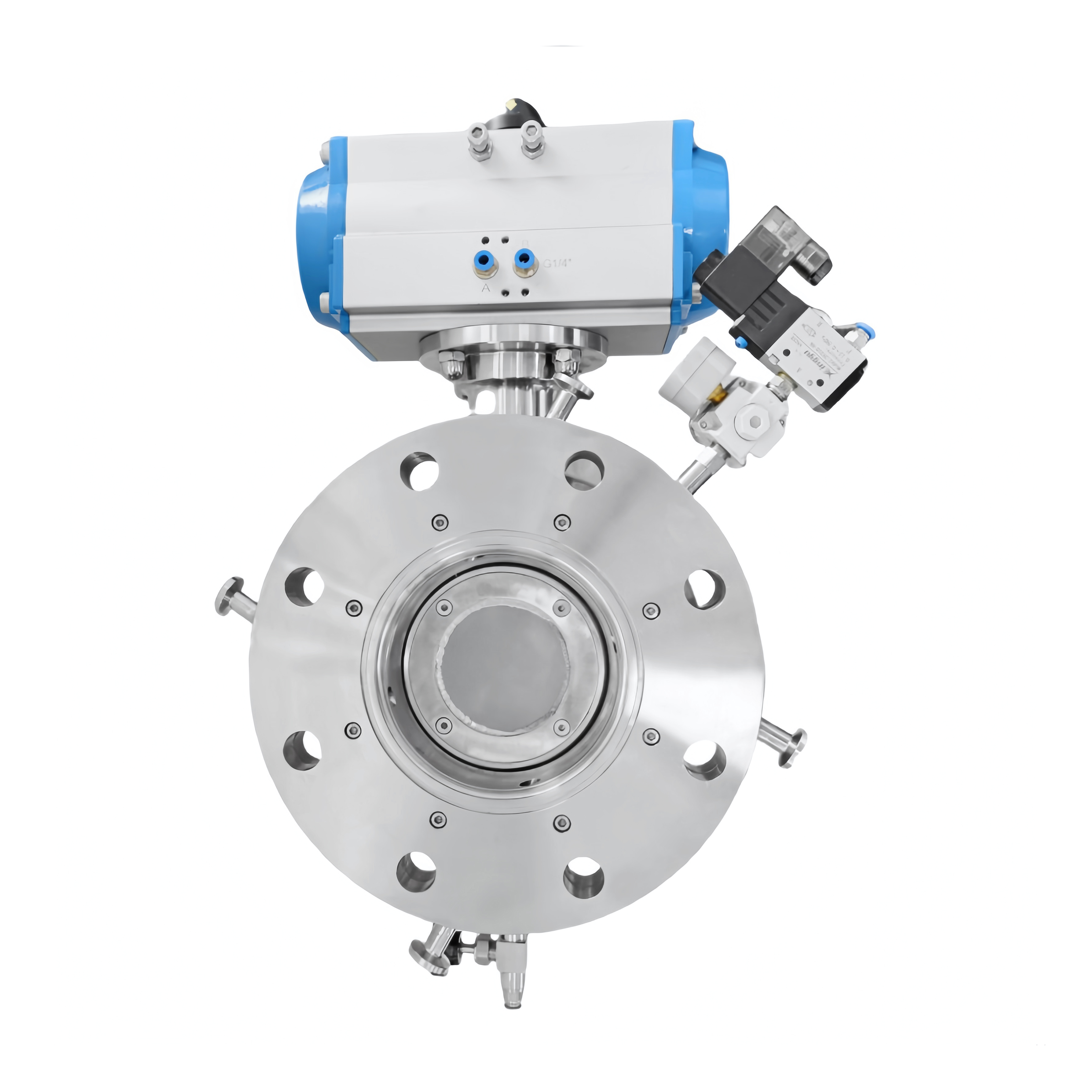

Aseptic sampling valve

PW series of aseptic-type sampling valve system should be carry out disinfection and sterilization processing (SIP) before and after it is used for sampling each time. Material is sealed with the diaphragm directly. There is no dead ends in the valve and easy to clean. it also can be continuous, and the sterile sampling at any time. And it is Widely used in the areas: wine,beverages, milk food, bio-pharmaceutical industry.

- Overview

- Recommended Products

Detailed Description

Aseptic Sampling Valve – SIP Process Integration

Before initiating the sampling process, the first critical step is the Sterilization-In-Place (SIP) procedure. During this stage, the valve is kept in a closed position to ensure all internal surfaces are properly sterilized.

To begin sampling, the valve is opened either by rotating the manual handle (for adjustable manual valves) or by activating the actuator (for automated versions). This action lifts the diaphragm and opens the shaft core, allowing sterile liquid to flow through the valve and into the sampling line.

After sampling is complete, the actuator is reversed to close the diaphragm valve. At this stage, the valve maintains a sterile connection between the two attached hoses, enabling another round of SIP sterilization to ensure full hygienic integrity of the system.

This aseptic sampling valve is designed for use in cleanroom environments and is ideal for applications in pharmaceutical, biotechnology, dairy, and beverage industries, where sanitary processing and contamination prevention are paramount.

Parameter

| Technical data | ||

| Material | Contact product parts | 316L(1.4404) |

| non-contact product parts | 304(1.4301) | |

| Provide EN 10204 3.1B certificate | ||

| Seal material | standard | EPDM |

| option | Silicone, FPM, PTFE | |

| All seal materials comply with FDA 177.2600 | ||

| Temperature | Running working temperature | -20~+135℃(EPDM) |

| Sterilization temperature | 150℃(max20min) | |

| Pressure | Working pressure | ≈10bar |

| Control air pressure | 5~8bar | |

| Surface treatment | Internal surface | Ra < 0.8μm |

| External surface | Grit blasting | |

| Connection | Connection method:welding、thread、clamp | |

PW--1 series

| Size | A | B | C | d | D | E | H | K | L |

| DN6 | 8 | 30 | 50.5 | 6 | 8 | 10 | 97 | 65 | 87 |

| DN8 | 8 | 30 | 50.5 | 8 | 10 | 12 | 97 | 65 | 87 |

PW--1 series

PW--2 series

| Size | A | B | C | D | d1 | D1 | D2 | E | F | G | H | k | L |

| DN6 | 8 | 30 | 25.2 | 50.5 | 6 | 8 | 10 | 25.4 | BSP 1/2” | 110.5 | 80 | 60 | 87 |

| DN8 | 8 | 30 | 25.2 | 50.5 | 8 | 10 | 12 | 25.4 | BSP 1/2” | 110.5 | 80 | 60 | 87 |

PW--2 series