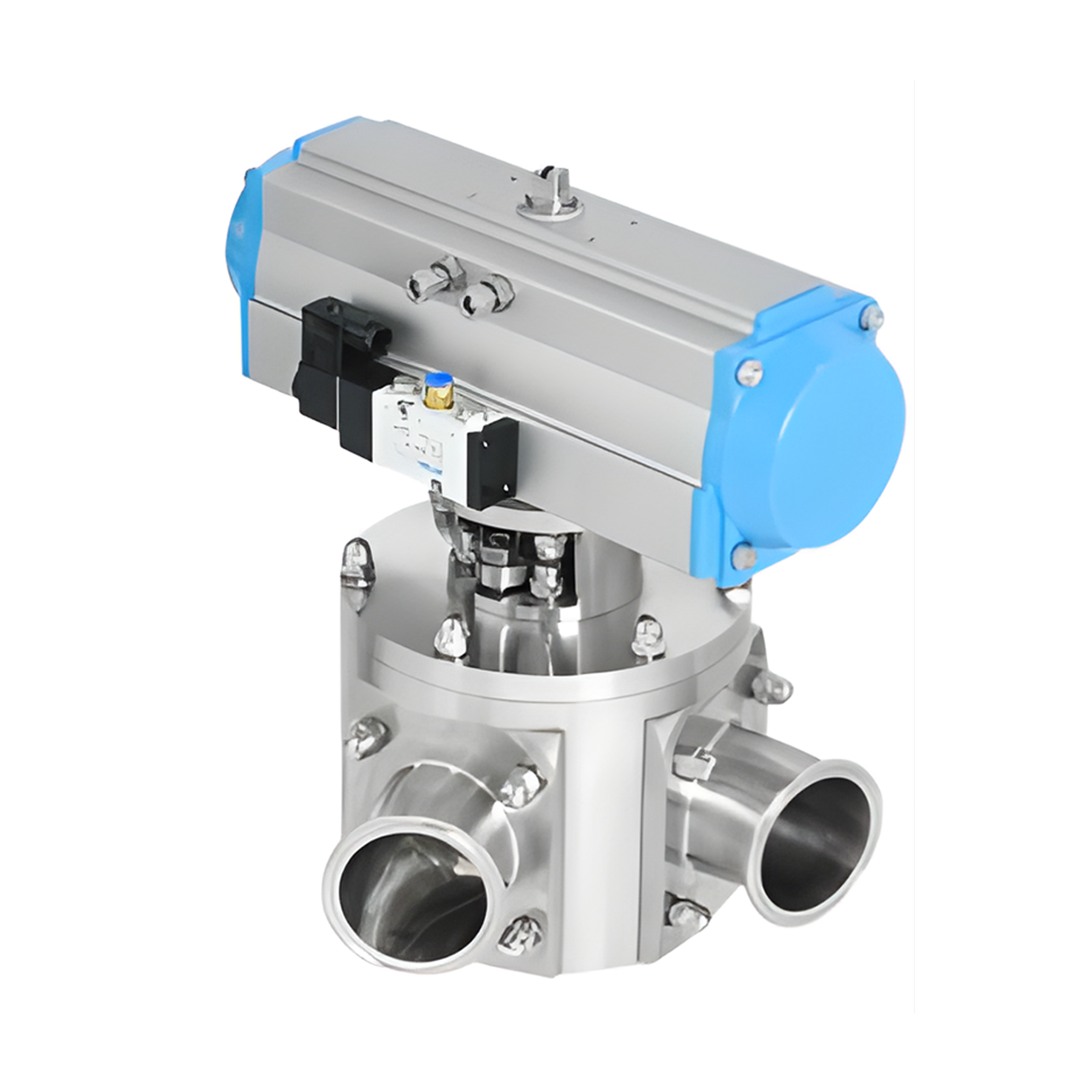

radial diaphragm valve

The Radial Diaphragm Valve is a compact, hygienic valve solution designed to ensure complete drainability and zero dead leg, making it ideal for critical applications in pharmaceutical, biotechnology, and high-purity processing industries. Its unique radial design enables direct, flush sealing with process outlets such as tank bottoms or sample points, minimizing product hold-up and contamination risk. Engineered with high-grade stainless steel and FDA-compliant diaphragm materials, the valve supports full CIP/SIP compatibility and meets stringent global standards including ASME BPE and GMP. Available with multiple actuation and control options, the Radial Diaphragm Valve combines reliability, cleanability, and performance in a space-saving design.

- Overview

- Recommended Products

Detailed Description

The Radial Diaphragm Valve is a precision-engineered, high-performance solution designed for applications demanding ultra-clean, fully drainable flow paths with no dead legs. Its unique radial body geometry enables the diaphragm to seal flush with the tank or pipeline outlet, ensuring complete product discharge and eliminating contamination risks. Manufactured from high-purity SS316L stainless steel and equipped with FDA- and USP Class VI-compliant diaphragms (including EPDM, PTFE/EPDM, FPM, and Silicone), the valve supports stringent sanitary requirements. With an internal surface finish of Ra ≤ 0.4 µm and optional electropolishing (SF1/SF4), it complies with global standards such as ASME BPE, GMP, and EHEDG. The compact footprint allows flexible mounting in tight spaces—whether vertical or horizontal—making it ideal for use in tank bottom outlets, sampling ports, and drainage lines. This automation-ready valve is available with manual, pneumatic, or electric actuators, and supports smart control systems with proximity sensors, control tops, or positioners. Fully CIP/SIP compatible and 100% tested for pressure and integrity, the Radial Diaphragm Valve delivers reliable, validated performance for pharmaceutical, biotechnology, and high-purity processing environments.