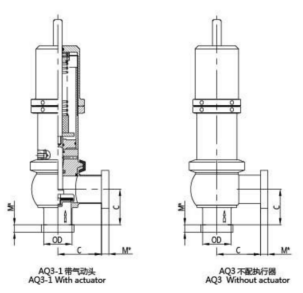

AQ3 sanitary safety valve

AQ3 system valve is a sanitary stainless steel safety valve, its design makes it adequate forprotection of installations in the pharmaceutical industry. It is used to perform pressure bypassfor safety purposes in order to protect lines, pumps. fittings, tanks, etc.

- Overview

- Recommended Products

Detailed Description

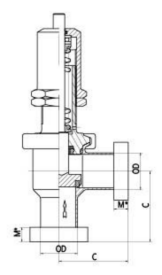

Under normal operating conditions, this pressure relief valve remains in a closed position. It is factory-calibrated to a specific safety pressure by adjusting the internal spring using the pressure nut. This pre-set pressure limit acts as a safeguard to protect the processing system from overpressure and potential damage.

When the system pressure exceeds the calibrated threshold, the valve automatically opens, allowing excess fluid to pass through. This immediate pressure release helps maintain system stability and ensures safe operation within sanitary processing lines.

For enhanced versatility, the valve can also be supplied with a manual handle. This feature enables partial opening of the valve to allow the controlled passage of cleaning agents during CIP (Clean-in-Place) processes, ensuring optimal hygiene without disassembly.

Made from high-quality stainless steel, the valve is ideal for use in dairy, beverage, pharmaceutical, and food industries requiring reliable, sanitary pressure relief solutions.

Parameter

| Technical data | ||

| Material | Contact product parts | 304L/316L(1.4307/1.4404) |

| non-contact product parts | 304(1.4301) | |

| Provide EN 10204 3.1B certificate | ||

| Seal material | standard | EPDM |

| option | SILICONE, PTFE, FPM, NBR | |

| Seal materials comply with FDA 177.2600 | ||

| Temperature | Running work temperature | -20~+135℃(EPDM) |

| Sterilization temperature | 150℃(max20min) | |

| Surface treatment | Internal surface | Ra ≤ 0.8um |

| External surface | Grit blasting | |

| Connection | Connection standard | welded end: DIN 11850 series2 |

| welded end: INCH pipe standard | ||

| Connection method: welding,thread、 clamp, flange | ||

| Pressure |

Control air pressure |

0-3bar/0-6bar/0-10bar(According to the role of spring) |

| 5~8bar | ||

| Size | C | OD | M/DIN Clamp |

| DN25 | 60 | 29*1.5 | 21.5 |

| DN32 | 60 | 35*1.5 | 21.5 |

| DN40 | 70 | 41*1.5 | 21.5 |

| DN50 | 80 | 53*1.5 | 21.5 |

| DN65 | 95 | 70*2.0 | 28 |

| DN80 | 115 | 85*2.0 | 28 |

| DN100 | 125 | 104*2.0 | 28 |

DIN standard

| Size | C | OD | M/3A Clamp |

| 1” | 60 | 25.4*1.65 | 12.7 |

| 1 1/4” | 60 | 31.75*1.65 | 12.7 |

| 1 1/2” | 70 | 38.1*1.65 | 12.7 |

| 2” | 80 | 50.8*1.65 | 12.7 |

| 2 1/2” | 95 | 63.5*1.65 | 12.7 |

| 3” | 115 | 76.2*1.65 | 12.7 |

| 4” | 125 | 101.6*2.11 | 15.8 |

3A standard

| Size | C | OD | M*(DIN Clamp) |

| DN25 | 50 | 29*1.5 | 12.7 |

| DN32 | 55 | 35*1.5 | 12.7 |

| DN40 | 57 | 41*1.5 | 12.7 |

| DN50 | 65 | 53*1.5 | 12.7 |

| DN65 | 80 | 70*2.0 | 12.7 |

| DN80 | 95 | 85*2.0 | 12.7 |

| DN100 | 115 | 104*2.0 | 15.8 |

DIN standard

| Size | C | OD | M*(3A Clamp) |

| 1” | 50 | 25.4*1.65 | 12.7 |

| 1 1/4” | 55 | 31.75*1.65 | 12.7 |

| 1 1/2” | 57 | 38.1*1.65 | 12.7 |

| 2” | 65 | 50.8*1.65 | 12.7 |

| 2 1/2” | 80 | 63.5*1.65 | 12.7 |

| 3” | 95 | 76.2*1.65 | 12.7 |

| 4” | 115 | 101.6*2.11 | 15.8 |

3A standard