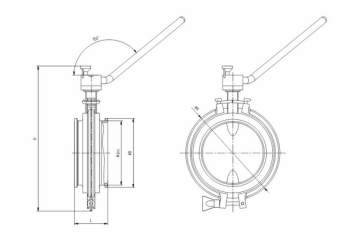

powder butterfly valve

The Powder Butterfly Valve is a compact, high-efficiency valve specifically designed for handling powdered and granular materials. It is widely used in food, pharmaceutical, chemical, plastic, and feed processing industries. Installed at the outlet of hoppers, bins, or silos, the valve operates by gravity or pneumatic control to regulate material flow. With excellent sealing performance and hygienic design, it effectively prevents dust leakage and cross-contamination. This valve is an ideal solution for safe, clean, and reliable bulk material handling.

- Overview

- Recommended Products

- Designed specifically for powders and granules to prevent bridging and blockages

- Compatible with pneumatic systems for automatic discharge control

- Available in food-grade stainless steel options to meet sanitary standards

- Easy to install below silos, bins, hoppers, screw feeders, and conveyors

- Reliable sealing performance to avoid dust escape and product loss

- Supports CIP/SIP cleaning, ensuring hygienic operation in sensitive environments

Detailed Description

The Powder Butterfly Valve is a specialized valve designed for handling bulk powder and granular materials. It is primarily used for controlling the flow at the discharge outlets of hoppers, bins, silos, and intermediate bulk containers (IBCs). Ideal for applications across industries such as food processing, pharmaceuticals, chemicals, plastics, construction materials, and animal feed, this valve provides reliable shut-off and flow control in powder handling systems.

This valve operates based on the natural gravity discharge of dry bulk materials and can also be integrated into pneumatic conveying systems for automated flow control. The powder butterfly valve can be mounted beneath hoppers, silos, screw conveyors, or other bulk material transfer equipment, serving as a key gravity flow control valve in material transfer applications.

The sealing system is optimized to minimize dust leakage and prevent contamination, while the smooth opening and closing mechanism reduces the risk of material bridging or clogging, making it especially suitable for fine powders, granules, and dry ingredients.

Key Advantages:

Whether used as a hopper discharge valve, a dry material shut-off valve, or in bulk powder transfer, the powder butterfly valve ensures efficient, dust-tight, and hygienic material flow control for a wide range of industrial processes.

Parameter

| DIN | NPS | H | L | K | D | DIN 11850 | ASTM-BPE | ISO 1127 | GB/T 17395 |

| series 2 | series 1 | ||||||||

| Φdxs | Φdxs | Φdxs | Φdxs | ||||||

| DN200 | 8.0° | 370 | 80 | 283 | 217.7 | 204×2 | 203.2×2.77 | 219.3×2.6 | 219×2 |

| DN250 | 10.0° | 420 | 80 | 283 | 268.5 | 254×2 | 254×2.77 | 273×2.9 | 273×2 |