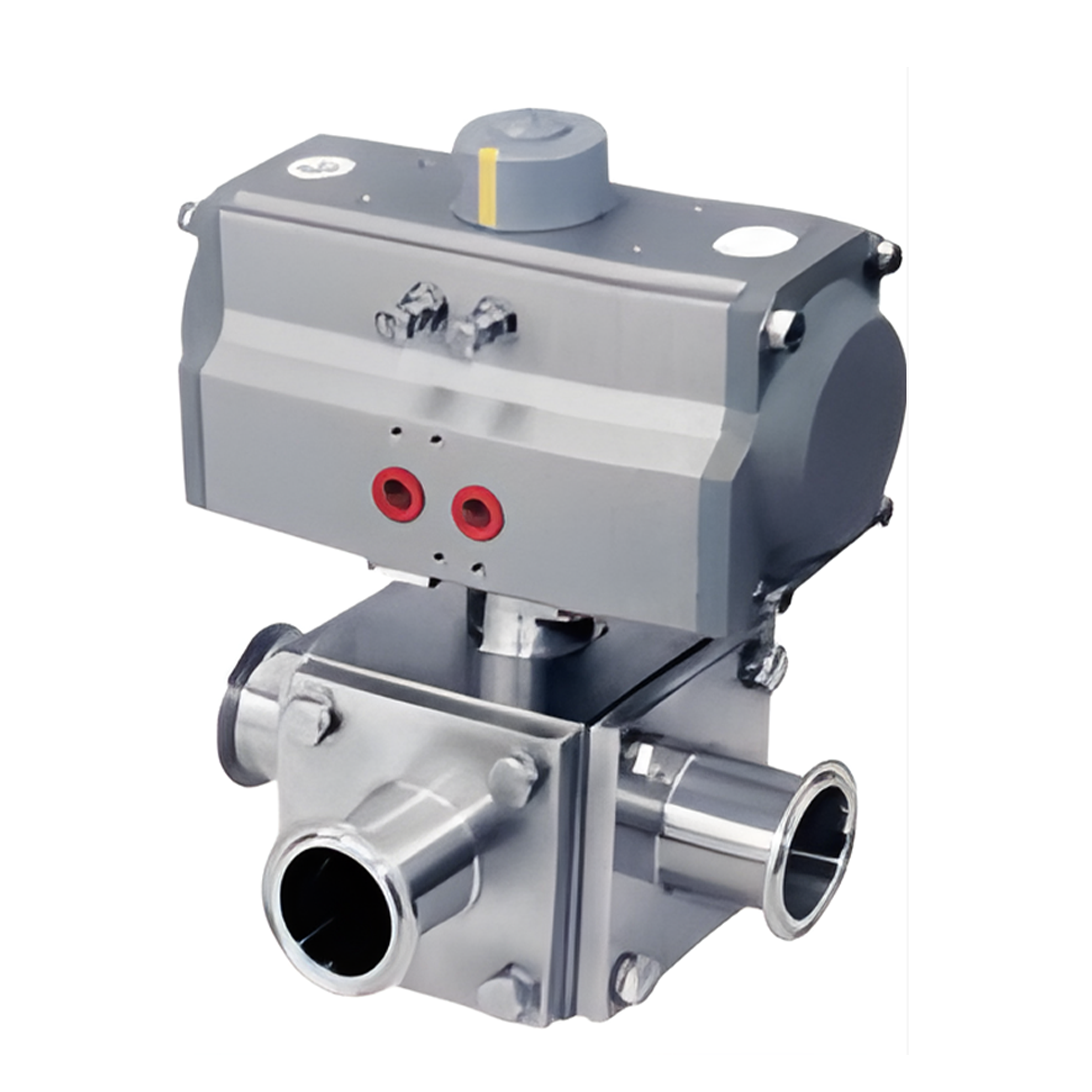

Sanitary divert valve

Pneumatic Single-Seat Valve

This hygienic valve is designed to safely separate two different media flowing through the same valve, preventing cross-contamination. It features a proven single-seat platform with pneumatic control, offering reliable performance in dairy, beverage, and pharmaceutical applications. Compact, easy to clean (CIP/SIP compatible), and ideal for sanitary fluid processing lines.

- Overview

- Recommended Products

Detailed Description

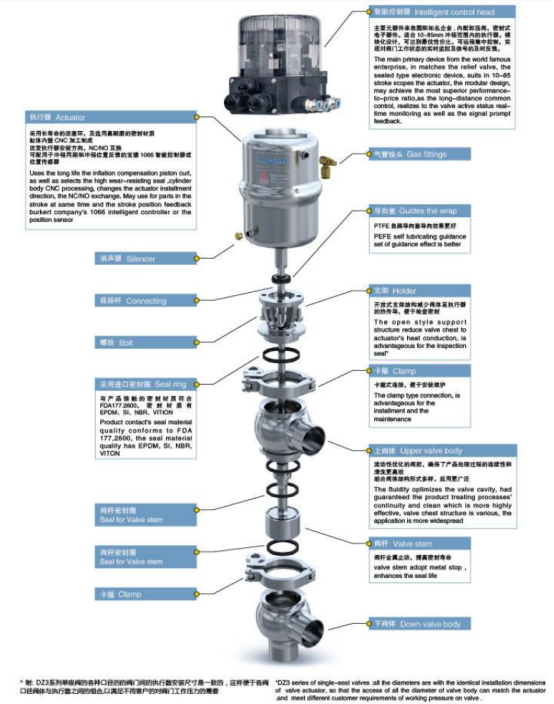

Hygienic Pneumatic Single-Seat Valve for Fluid Separation

The single-seat mix-proof valve is a hygienic, pneumatically actuated seat valve designed for applications requiring the safe separation of two different product flows through a single valve body. Based on a proven single-seat valve platform, this advanced design ensures zero cross-contamination, precise control, and easy monitoring of valve operation, making it an ideal solution for fluid processing systems in demanding hygienic industries.

Its flexible and sanitary construction makes it especially suitable for use in the dairy, beverage, and pharmaceutical sectors, where product purity, CIP/SIP compatibility, and process safety are critical. The valve efficiently prevents fluid mixing even when different media pass through the same unit, supporting optimized product changeovers and secure line cleaning.

Key advantages:

Hygienic mix-proof design for cross-contamination prevention

Pneumatic operation for reliable and automated process control

Based on a mature and robust single-seat valve platform

Ideal for dairy processing, beverage manufacturing, and pharmaceutical-grade applications

Designed for clean-in-place (CIP) and sterilize-in-place (SIP) compatibility

This valve is an essential component in sanitary fluid handling systems, offering both performance and safety in processes where media separation is vital.

Parameter

| Technical data | ||

| Material | Contact product parts | 316L(1.4404) |

| non-contact product parts | 304(1.4301) | |

| Provide EN 102043.1B certificate | ||

| Seal material | Standard | EPDM |

| Option | NBR、FPM、Silicone | |

| All seal materials comply with FDA 177.2600 | ||

| Temperature | Running working temperature | -20~+135℃(EPDM) |

| Sterilization temperature | 150℃(Max 20min) | |

| Pressure | Working pressure | 0~5bar(standard) |

| Accepting high pressure requirement | ||

| Control air pressure | 5~8bar | |

| Surface treatment | Internal surface | Ra≤0.8μm |

| External surface | Grit blasting | |

| Connection | Connection standard | welded end:DIN 11850 series2 |

| welded end:INCH pipe standard | ||

| Connection method:welding、thread、clamp、flange | ||

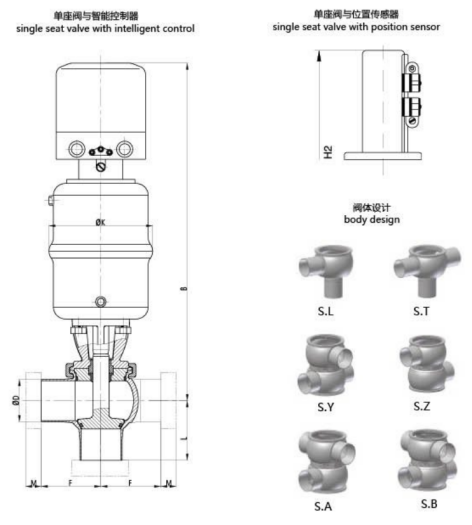

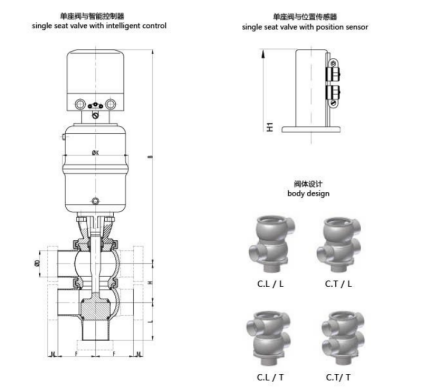

| Option | Intelligent controler | 24V DC |

| 1/2 electromagnetism valve | ||

| Position sensor | 24V DC | |

| 2 NPN/PNP position sensor | ||

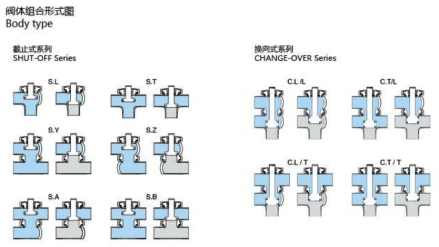

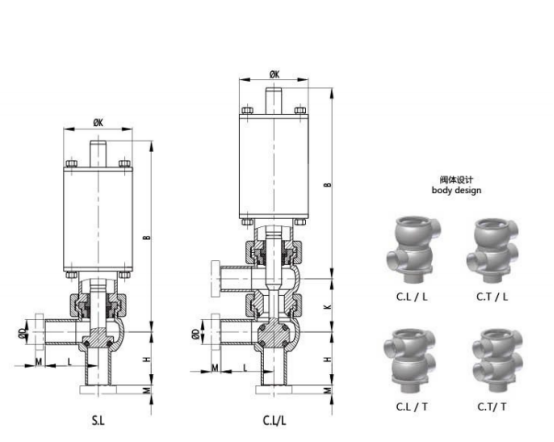

Globe type series:

| dimensions(mm) | ||||||

| DN | B | H | K | F | D | MDIN clamp) |

| DN25 | 295 | 50.5 | 90 | 55 | 29×1.5 | 21.5 |

| DN40 | 301 | 63 | 90 | 65 | 41×1.5 | 21.5 |

| DN50 | 326 | 76 | 130 | 75 | 53×1.5 | 21.5 |

| DN65 | 414 | 93 | 195 | 90 | 70×2.0 | 28 |

| DN80 | 418 | 109 | 195 | 110 | 85*2. | 28 |

| DN100 | 432 | 127 | 195 | 120 | 104*2.0 | 28 |

| INCH | M(3A clamp) | |||||

| 1.0" | 295 | 50.5 | 90 | 55 | 25.4×1.65 | 12.7 |

| 1.5“ | 301 | 63 | 90 | 65 | 38.1×1.65 | 12.7 |

| 2.0" | 325 | 76 | 130 | 75 | 50.8*1.65 | 12.7 |

| 2.5" | 335 | 88 | 130 | 85 | 63.5×1.65 | 12.7 |

| 3.0" | 417.5 | 101 | 195 | 95 | 76.2*1.65 | 12.7 |

| 4.0" | 432 | 127 | 195 | 120 | 101.6*2.11 | 15.8 |

Divert series:

| dimensions(mm) | ||||||

| DN | B | H | K | F | D | M(DIN damp) |

| DN25 | 295 | 50.5 | 90 | 55 | 29×1.5 | 21.5 |

| DN40 | 301 | 63 | 90 | 65 | 41×1.5 | 21.5 |

| DN50 | 326 | 76 | 130 | 75 | 53×1.5 | 21.5 |

| DN65 | 414 | 93 | 195 | 90 | 70×2.0 | 28 |

| DN80 | 418 | 109 | 195 | 110 | 85*2.0 | 28 |

| DN100 | 432 | 127 | 195 | 120 | 104*2.0 | 28 |

| INCH | M(3A clamp) | |||||

| 1.0' | 295 | 50.5 | 90 | 55 | 25.4×1.65 | 12.7 |

| 1.5' | 301 | 63 | 90 | 65 | 38.1×1.65 | 12.7 |

| 2.0' | 325 | 76 | 130 | 75 | 50.8*1.65 | 12.7 |

| 2.5' | 335 | 88 | 130 | 85 | 63.5×1.65 | 12.7 |

| 3.0' | 417.5 | 101 | 195 | 95 | 76.2*1.65 | 12.7 |

| 4.0' | 432 | 127 | 195 | 120 | 101.6*2.11 | 15.8 |

Mini single valve

| dimensions(mm) | ||||||

| DN | B | H | K | L | D | MDIN clamp) |

| DN10 | 144.5 | 40 | 52 | 40 | 13×1.5 | 12.7 |

| DNi5 | 144.5 | 40 | 52 | 40 | 19×1.5 | 12.7 |

| INCH | B | H | K | L | OD | M3A camp) |

| 1月2日 | 144.5 | 40 | 52 | 40 | 12.7x1.65 | 12.7 |

| 3/4' | 144.5 | 40 | 52 | 40 | 19.05×1.65 | 12.7 |