Tank bottom diaphragm valve

The Tank Bottom Diaphragm Valve is designed for direct mounting at the lowest point of a tank or vessel to ensure complete and hygienic drainage. Its zero dead leg design eliminates product hold-up, making it ideal for applications that require high levels of cleanliness and sterilization. Made from high-grade stainless steel with a polished internal finish, the valve meets international standards such as ASME BPE and FDA. It is fully compatible with CIP/SIP processes and available in manual or automated configurations for flexible, reliable flow control in pharmaceutical, biotech, and food-grade systems.

- Overview

- Recommended Products

Detailed Description

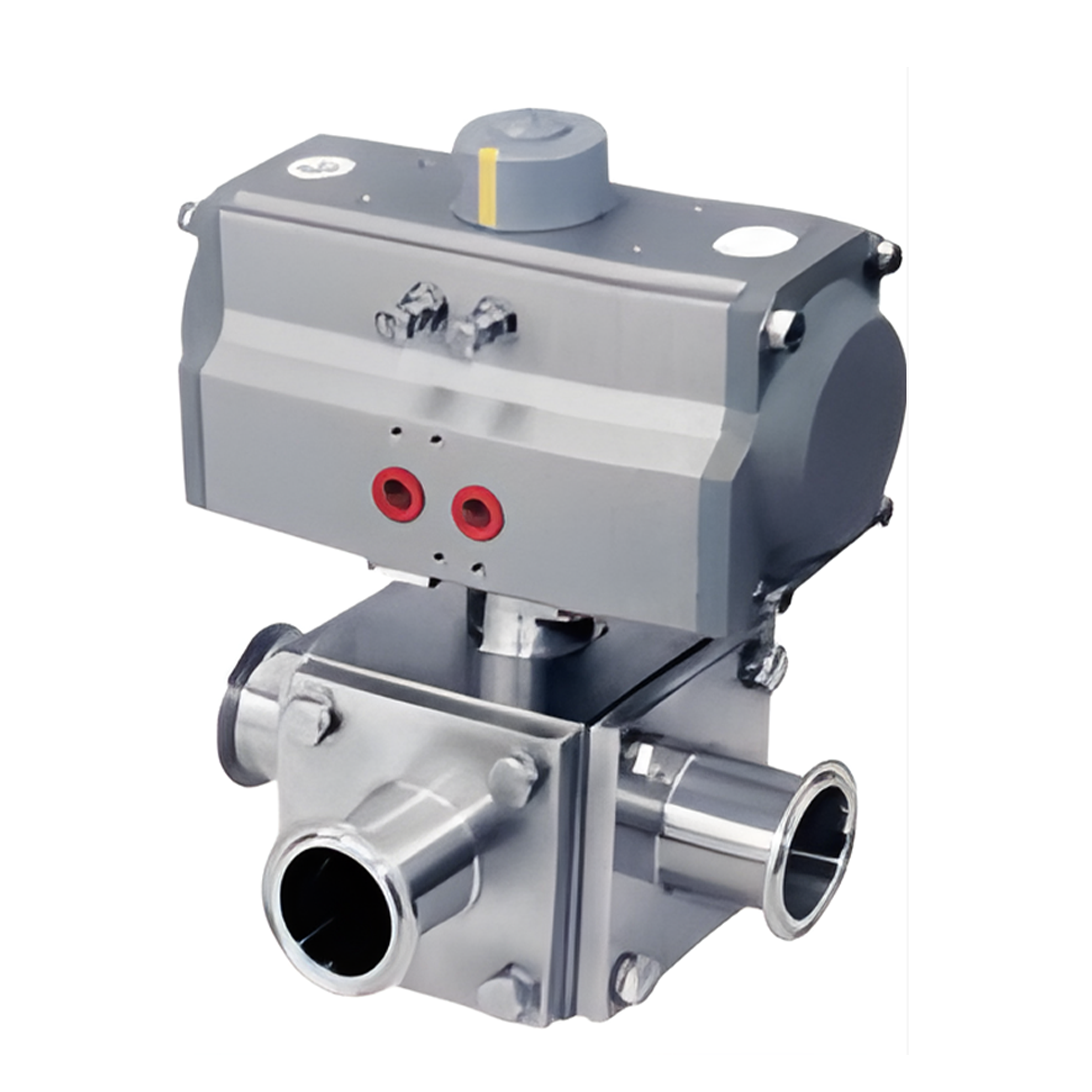

The Tank Bottom Diaphragm Valve is a hygienic flow control solution specifically designed for direct installation at the lowest point of a tank or vessel to enable complete, drainable, and contamination-free discharge. Featuring a zero dead leg design and flush-mounted diaphragm seat, it ensures no product hold-up and supports full CIP/SIP compatibility for sterile applications. Manufactured from high-purity stainless steel (such as SS316L) with internal surface finishes of Ra ≤ 0.4µm and optional electropolishing, the valve meets stringent standards including ASME BPE, FDA, and 3-A. Its compact, sloped body promotes self-draining, while the diaphragm sealing mechanism offers hermetic separation between the process media and actuator. Available in manual, pneumatic, or electric actuation with optional control tops and position feedback, this valve is ideal for pharmaceutical, biotechnology, and food industries where cleanliness, efficiency, and compliance are critical. All valves are 100% tested and delivered with full documentation and traceability to support validation and GMP compliance.

Specifications

Tank Outlet Diaphragm Valve – Hygienic, Reliable, and Optimized for Drainage

Our Tank Outlet Diaphragm Valve is engineered to deliver high-performance and sanitary flow control at the lowest point of process tanks or vessels. The valve features a unique zero-dead-angle sealing design that ensures complete drainage and eliminates contamination risk. Constructed with FDA-compliant sealing materials such as EPDM+PTFE dual seals, pure EPDM, Teflon PTFE, FPM, and Silicone, it is suitable for demanding hygienic applications. The internal surface finish is available with Ra ≤ 0.4µm or electropolished to SF1/SF4 standards, fully compliant with ASME BPE.

The valve is highly versatile, supporting manual operation, pneumatic or electric actuation, and easily interchangeable components. It is available in multiple configurations including 2-way, 3-way, U-type, T-type, multi-port, and tank bottom styles to meet various system layouts. Each valve is 100% hydraulically tested and visually inspected to ensure reliable, leak-free performance.

Operation Options:

Handles: Plastic or stainless steel handwheel

Actuators: Pneumatic (plastic or stainless steel), Electric

Control Units: Proximity sensors, stroke limiters, C-top (on/off), and IL-top (positioner)

Why Choose Our Tank Bottom Diaphragm Valve?

Over 20 years of manufacturing experience with more than 600,000 valves produced.

Continuous design improvements and performance optimizations ensure consistent, reliable quality.

Zero dead space design supports full cleanability and sterility.

High-grade imported seals sourced from Denmark for enhanced durability and sealing integrity.

Certifications and Standards:

Complies with 3-A, FDA, PED 2014/68/EU, ISO9001:2008, and meets DIN, SMS, ISO/IDF, BS/RJT, and ASME BPE standards.

| dimensions(mm) | ||||||||||||||

| DIN 11866 senes 1 | DIN 11866 series 3 | |||||||||||||

| Sze | DN10 | DN15 | DN20 | DN25 | DN32 | DN40 | DN50 | DN85 | 1/2° | 34° | 1" | 1-1/2° | 2 | 2002/1/2 |

| D0 | 10 | 16 | 20 | 26 | 32 | 38 | 50 | 66 | 9.4 | 15.75 | 22.1 | 34.8 | 47.5 | 60.2 |

| ZD | 13 | 19 | 23 | 29 | 35 | 41 | 53 | 70 | 12.7 | 19.05 | 25.4 | 38.1 | 50.8 | 63.5 |

| A | 100 | 100 | 120 | 120 | 140 | 140 | 160 | 210 | 100 | 100 | 120 | 140 | 160 | 210 |

| B | 24 | 24 | 25 | 25 | 29 | 29 | 33 | 35 | 24 | 25 | 25 | 29 | 33 | 35 |

| K1 | 85 | 85 | 85 | 85 | 110 | 110 | 110 | 110 | 85 | 85 | 85 | 110 | 110 | 110 |

| K2 | 57 | 57 | 86 | 86 | 102 | 102 | 124 | 162 | 57 | 88 | 86 | 102 | 124 | 162 |

| K3 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| MDIN clamo | 18 | 18 | 18 | 21.5 | 21.5 | 21.5 | 21.5 | 28 | ||||||

| WSMS clarnp | 12.7 | 12.7 | 12.7 | 12.7 | 12.7 | 12.7 | ||||||||