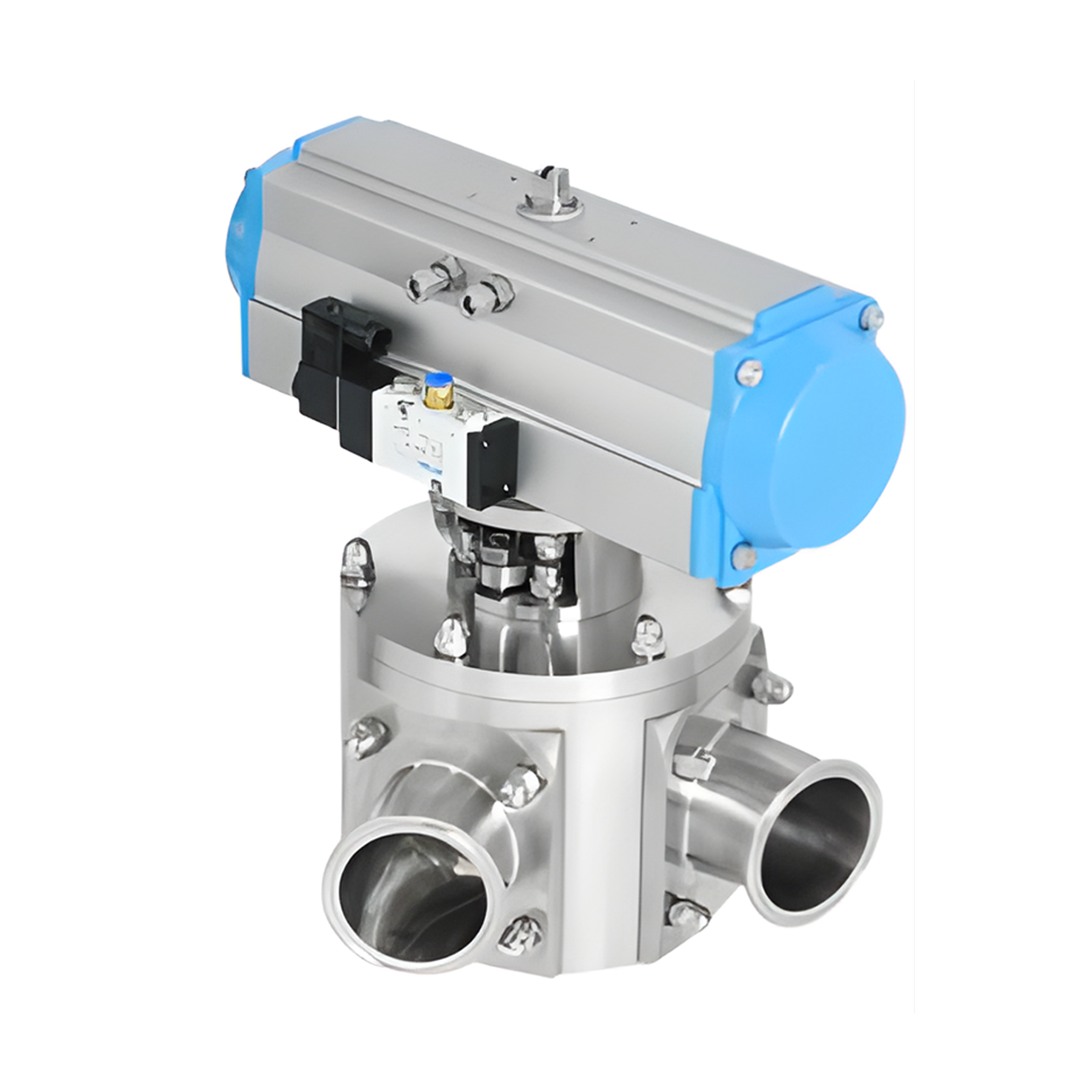

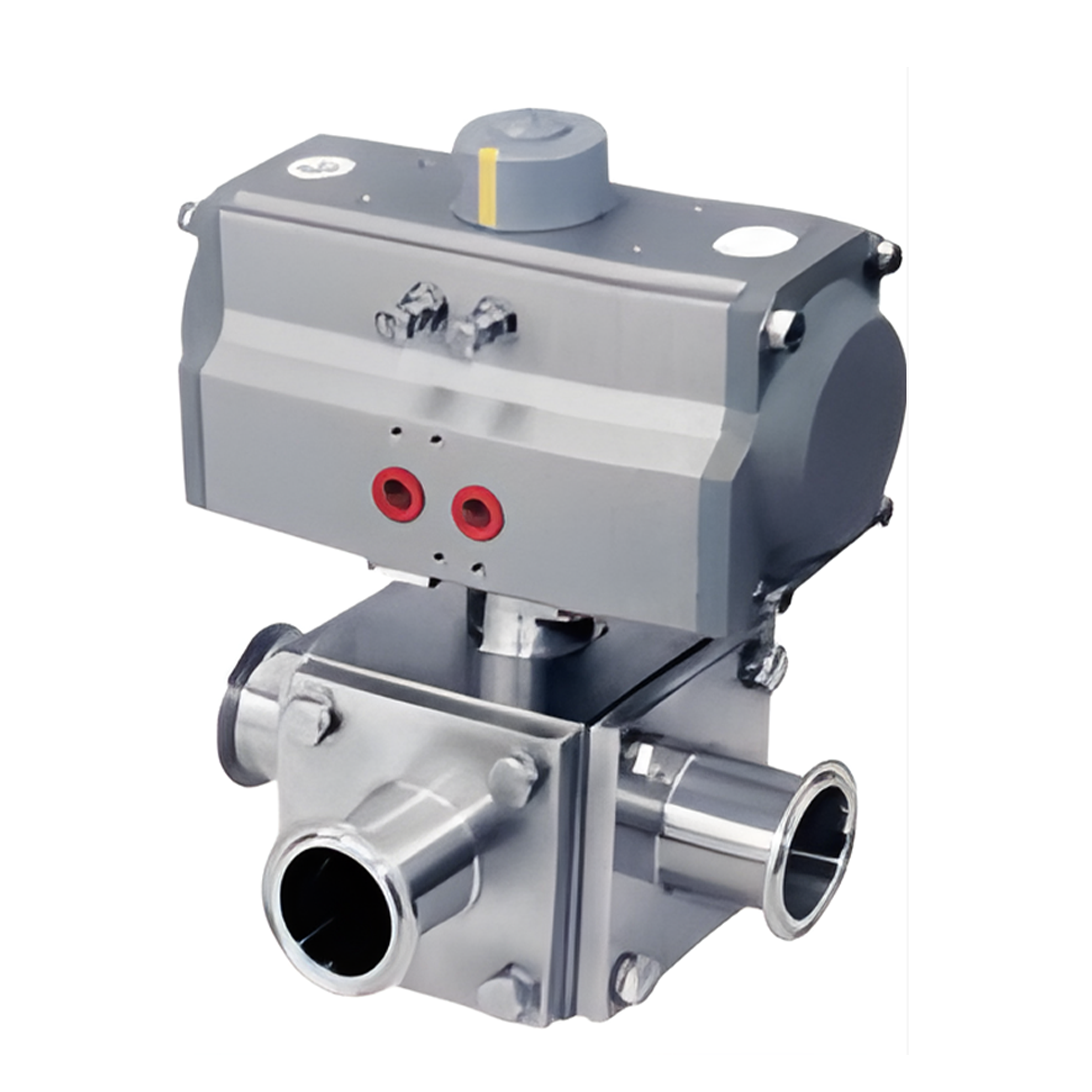

Directional Valve

The reversing valve is a valve that controls the flow direction of the medium through a rotating valve core. It can be used in conveying pipelines or gravity discharge. It is widely used in high-efficiency fluid control scenarios in the fields of chemical industry, new energy, pharmaceuticals, etc. Optional for use in different working conditions:

- Inflatable airbag, seal with 0 friction, 0 shedding, high sealing, significantly improving the service life of the valve seal.

- The Y-shaped structure is designed to have an angle of 120° and 135° between the valve body feed port and the two discharge ports. The valve core is driven to rotate through the drive device to realize the flow or cut between the inlet end and any outlet, thereby achieving the switching of two different flow directions. The inner channel curve type avoids rapid rotation angle of the runner.

- In a single-channel structure, the valve core is a plug-in structure with a small leakage volume, and the straight-through flow channel is designed to have a large flow rate.The valve body feed port and the two discharge ports are designed to have an angle of 135°.

- Dual-channel structure, the rotational shunt angle of this structure is designed to be 45°, 30°, etc. Due to its small rotation angle, the internal components are almost not affected by high-wear materials. If the material is abrasive.only the internal channel wear can provide the possibility of the valve core rotating by 180°,making the component life longer.

- Overview

- Recommended Products

- Standard size: 2"-12"

- Valve body material: 304, 316L, TA2, 2205, etc.

- Sealing material: static seal PTFE, RPTFE, PPL, PEEK, etc., inflatable seal silicone, FKM

- Surface treatment: Ra<0.6 (contact part with the medium)

- Connection method: flange, quick installation

- Working pressure: -0.1Mpa~+0.6Mpa

- Working temperature: -20℃~+250℃(depending on the sealing material)

- Commutation angle:90°, 120°, 135°

Detailed Description

Parameter