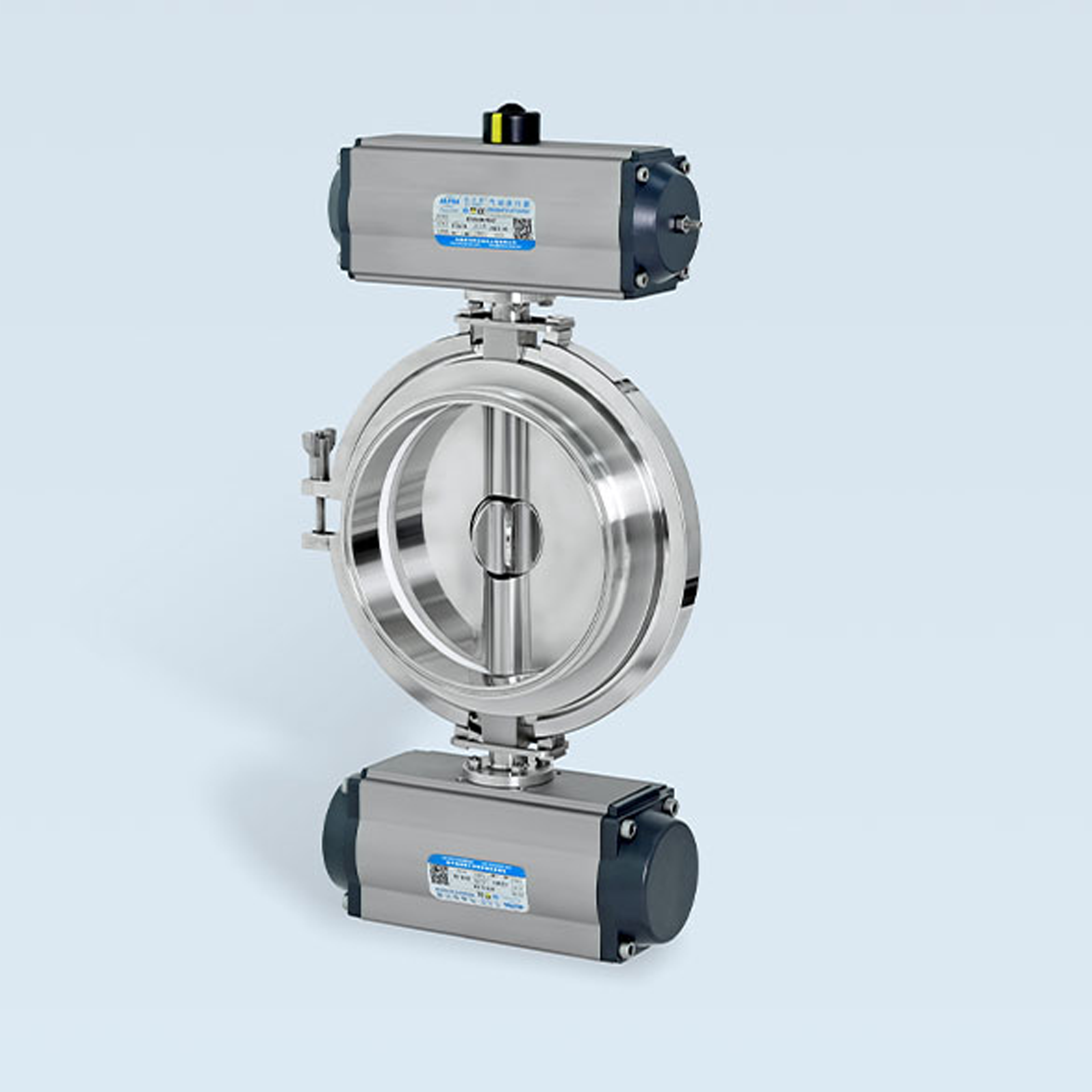

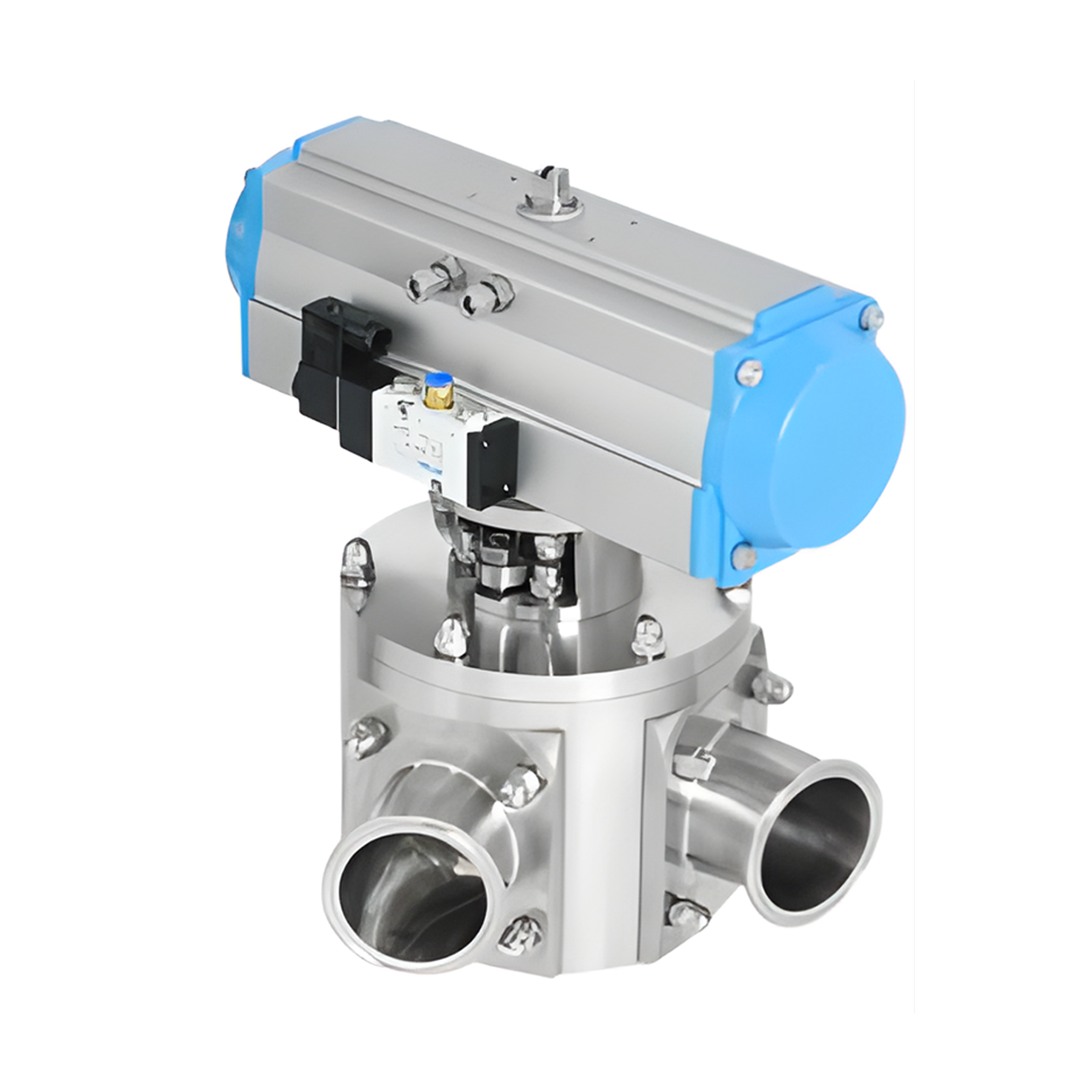

double dosing butterfly valve

The Double Dosing Butterfly Valve is a high-precision discharge valve designed for accurate dosing of powders and granules. Featuring a dual-rotor system—one for fast bulk feeding and another for fine metering—it delivers both efficiency and dosing accuracy. The valve is ideal for use in automated weighing and batching systems. Its modular, hygienic, quick-clamp design allows for easy cleaning and maintenance, making it an excellent choice for food, pharmaceutical, and chemical industries.

- Overview

- Recommended Products

- Dual-rotor structure for high-efficiency and high-accuracy dosing

- Coarse and fine metering combination for precision batch control

- Compatible with PLCs and industrial weighing systems

- Quick-clamp sanitary design for easy cleaning and maintenance

- Suitable for powders, granules, and dry bulk solids

- FDA-compliant seals and optional 304/316L stainless steel contact surfaces

- Perfect solution for automated powder handling and hygienic filling systems

- Contact with medium: 304 or 316L stainless steel

- Non-contact parts: 304 stainless steel

- PTFE (standard configuration)

- EPDM rubber, silicone rubber (optional)

- Contact surfaces: Ra < 0.4 μm

- Non-contact surfaces: Polished or electrolytically treated

Detailed Description

Double Dosing Butterfly Valve is a highly precise twin-rotor metering valve designed specifically for controlled dosing and discharge of powders and granular materials. The valve features two separate rotors: the larger rotor handles fast, coarse dosing, while the smaller rotor performs fine dosing to ensure high accuracy during material discharge. This dual-stage operation enables seamless switching from bulk feed to precision top-up, making it ideal for automatic batching and weighing systems.

The valve is intended to work in conjunction with a material weighing or recipe dosing system, allowing for automated, programmable control of fill volume or weight. Its modular quick-release clamp design allows for fast disassembly, cleaning, and reassembly, reducing downtime and ensuring hygiene compliance in food, pharmaceutical, chemical, and material processing industries.

Key Features & Advantages:

Parameter

Specifications:

Sizes: 6.0", 8.0", 10.0", 12.0"

Working Pressure: -0.1 MPa ~ +0.5 MPa

Working Temperature: -20°C to +135°C (depending on sealing material)

Metal Materials:

Sealing Materials (Options):

Surface Finish:

Connection Standards: ASME-BPE

Connection Methods: Welded, clamped, etc.

Actuation:

Large Rotor Actuator:

0–90° (butterfly rotor)

0–180° (star rotor)

Small Rotor Actuator:

0–180° actuator

Pneumatic motor or servo motor (optional)

| DIN | NPS | H | L | E1 | E2 | C |

DIN 11850 series 2 |

ASTM-BPE |

SO 1127 series 1 |

BS 4825 | GB/T 17395 |

| Φdxs | Φdxs | Φdxs | Φdxs | Φdxs | |||||||

| DN150 | 6.0" | 525 | 100 | 242 | 265 | 166.8 | 154×2 | 152.4×2.77 | 168.3×2.6 | 139.7×2 | 159×2 |

| DN200 | 8.0" | 578 | 100 | 242 | 265 | 217.7 | 204×2 | 203.2×2.77 | 219.1×2.6 | 168.3×2.6 | 219×2 |

| DN250 | 10.0" | 751 | 100 | 275 | 265 | 268.2 | 254×2 | 254×2.77 | 273×2.9 | 219.3×2.6 | 273×2 |

| DN300 | 12.0" | 890 | 120 | 332 | 290 | 319.3 | 304×2 | 304.8×2.77 | 323×2.9 | 273×2.6 | 324×2 |