rapid transfer port (RTP)

Alpha-Beta RTP System for Contained and Aseptic Transfer

Our Alpha-Beta Rapid Transfer Port (RTP) system is designed for safe, sterile, and contamination-free material transfer in pharmaceutical isolators, cleanrooms, and containment systems. With secure alpha-beta docking and a robust interlock mechanism, it ensures aseptic transfer of products or waste without compromising the sealed environment. Compatible with stainless steel and plastic beta containers, it’s ideal for applications requiring strict GMP compliance and high-level operator safety.

- Overview

- Recommended Products

- ◆ Body Material: 316L stainless steel (product contact parts) and POM/304 stainless steel (non-contact parts)

- ◆ Sealing Material: Fluorine rubber (FKM), silicone rubber — compliant with FDA 21 CFR 177.2600 (standard)

- ◆ Surface Finish: Ra < 0.4 µm (product contact surfaces); Ra < 0.8 µm (non-contact surfaces)

- ◆ Containment Level: Sealing classification up to OEB4

- Ready to Sterilize (RTS)

- Ready to Use (RTU)

Detailed Description.

Alpha Port Integration for Isolators and Transfer Systems – Secure, Aseptic Material Handling

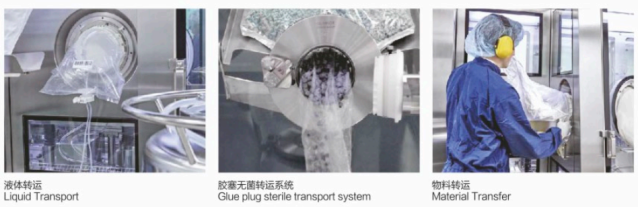

The Alpha port is designed to be integrated at the inlet and outlet points of isolators or containment transfer systems. It interfaces seamlessly with Beta containers—available in stainless steel or plastic. Operators can open the Alpha port door from inside the isolator via a glove port, allowing for the safe and aseptic transfer of materials into the Beta container.

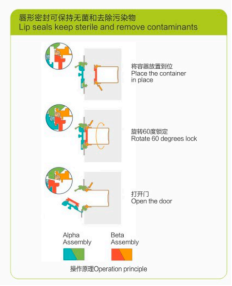

The system ensures that the Beta container can only be disengaged when the Alpha port door is fully closed, thereby maintaining a secure, contamination-free environment. The critical sealing remains intact throughout the docking and undocking process.

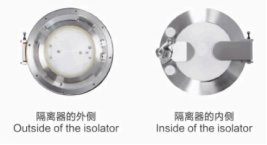

The rapid transfer port (RTP) system consists of two main components: the Alpha unit and the Beta unit. Each unit is equipped with its own door, high-performance seals, and a robust interlock mechanism. The Alpha unit is typically mounted on the wall of an isolator or glove box, while the Beta unit is portable and used for transferring products or waste in and out of the containment area.

When the Alpha and Beta units are properly docked, materials can be moved quickly and safely without breaching the sterile or contained environment. The interlock system on the Alpha port guarantees a secure and reliable Alpha-Beta docking, ensuring that the Alpha door cannot be opened unless the Beta unit is fully and correctly connected.

Parameter

| Specification |

Flange diameter |

Effective diameter |

Opening diameter |

| 105 | 225 | 85 | 156 |

| 190 | 315 | 170 | 268 |

| 270 | 400 | 250 | 348 |

| 350 | 475 | 330 | 428 |

The core of the transfer system is the Alpha port, whose secure interlock mechanism ensures complete safety during connection and disconnection operations. The system is based on the interaction between the Alpha and Beta components — each equipped with a door, locking mechanism, and sealing elements.

The Alpha unit is typically installed on isolators, RABS (Restricted Access Barrier Systems), biosafety cabinets, or cleanroom walls. The Beta unit consists of a container, bag, or similar device used for the safe transfer of components, solids, or liquids between sterile or contained environments.

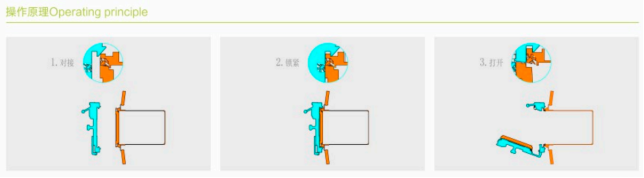

Manual 60° Rotation Connection:

The Alpha and Beta components are securely connected by manually rotating them 60 degrees. Upon proper docking, the doors of each component disengage from their respective housings and lock together as one unit. A lip seal ensures a reliable, airtight connection. At this point, the door can be opened without compromising sterility or containment integrity.

BetaBag Product Range

Available as direct supply or through component manufacturers:

Shelf Life: 24 months (on average)

Bag Volumes: Available in a wide range from 10L to 150L to suit various applications

| Product range | |||||||

| 105mm | 190mm | 270mm | 350mm | 460mm | |||

| ALPHA | ● | ● | ● | ||||

| BETA | Container | Stainless steel | ● | ● | ● | ● | ● |

| Polyethylene | ● | ● | ● | ● | ● | ||

| BetaBag | Tyvek | ● | ● | ||||

| PE/EVOH/PE | ● | ● | |||||

| Polyurethane | ● | ● | |||||

| Polyethylene continuous discharge bag | ● | ● | |||||

| Simulate containers | |||||||

| Stainless steel container(4 types of standards) | ||||||

| Container Standard | Φ | 300mm | 400mm | 500mm | 600mm | 700mm |

|

Standard type Autoclave container |

190 | |||||

| 270 | ● | |||||

| 350 | ● | |||||

|

Semi-standard Autoclave and H₂O sterilization containers |

190 | ● | ● | ● | ● | ● |

| 270 | ● | ● | ● | ● | ● | |

| 350 | ● | ● | ● | ● | ● | |

|

Customized by customers Using pre-designed parts |

190 | ● | · | ● | ● | ● |

| 270 | ● | ● | ● | ● | ● | |

| 350 | ● | ● | ● | ● | ● | |

| Blue racks,sizes,and components that are customized completely according to customer requirements-Contact our sales team | ||||||