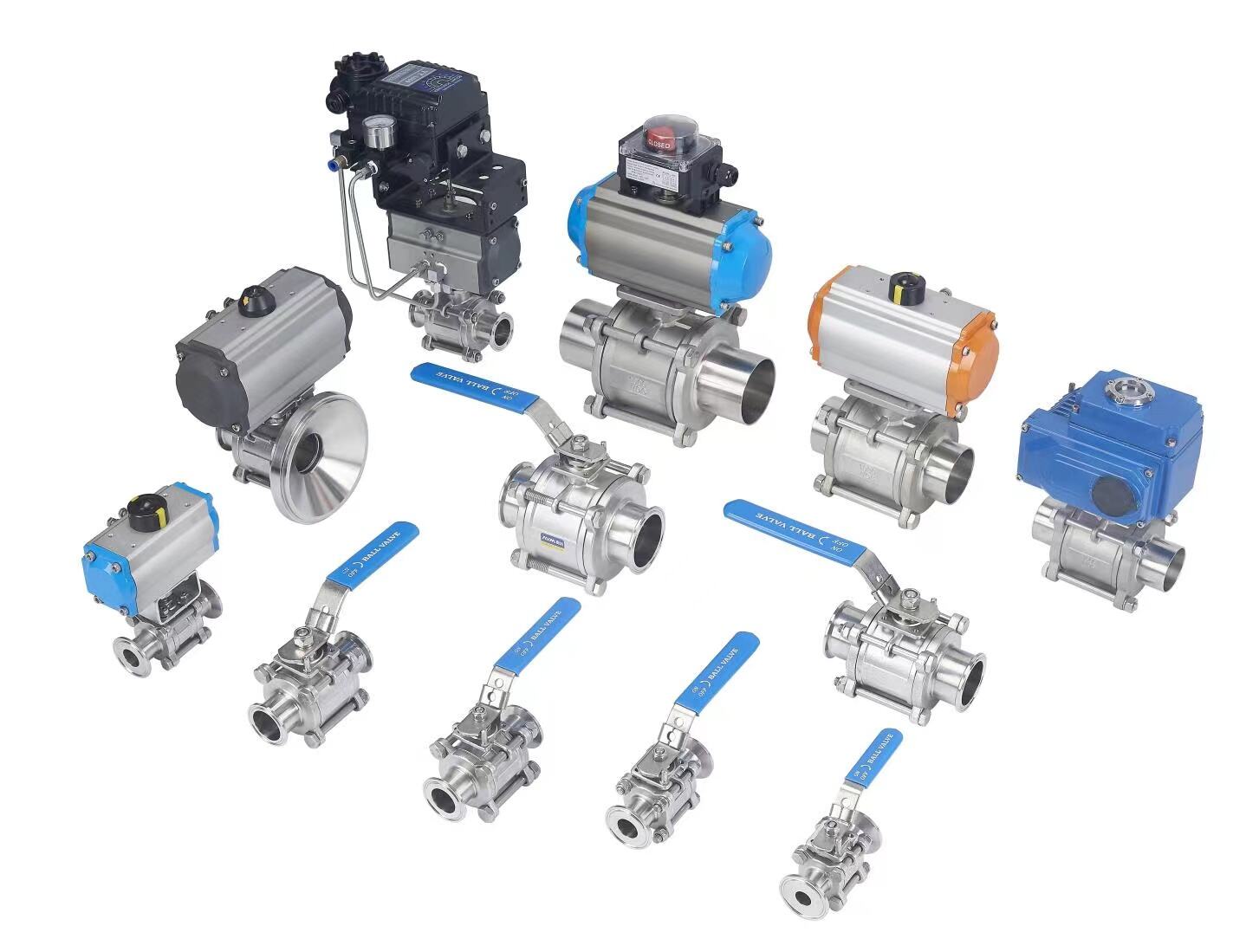

High-Standard Hygienic Valves for Ensuring Cleanliness in Sterile Production Processes

Hygienic Valves are designed to meet the most stringent sanitary requirements, ensuring that materials remain free from contamination during production. These valves are critical in industries like food processing, pharmaceuticals, and biotechnology, where cleanliness is paramount. Featuring smooth surfaces and easy-to-clean designs, Hygienic Valves minimize the risk of bacterial buildup and product contamination. They are built to withstand frequent cleaning and sterilization cycles, maintaining operational integrity while ensuring compliance with health and safety regulations.

Get A Quote