High containment powder sampling valve

Optional automation for integrated control and CIP/SIP compatibility.

- Overview

- Recommended Products

- Low retention, no dead corner, high cleanliness, small torque

- The airbag and plunger have no friction, so thatthe service life of the valve is extended.

Achieving high containment during sampling of potent or sensitive products is a major challenge in pharmaceutical and chemical production. The AVM high-containment sampling device is specifically engineered to ensure safe, clean, and fully controlled sampling without exposing operators or the environment to harmful substances.

Our system is designed around strict OEL (Operator Exposure Limit) requirements.

The OEL defines the maximum airborne concentration of an active substance that can be present in the production room without causing any risk to operator health.

AVM’s advanced sampling technology ensures an OEL performance of < 1 μg/m³, making it suitable for handling highly potent APIs and toxic powders.

The standard sampling container has a 250 ml (16 cu in) capacity and connects easily to existing process lines via a DN50 / 2.5" tri-clamp interface. The system integrates seamlessly with the AVM split butterfly valve, providing a reliable, contamination-free transfer between process and sampling points.

Key Advantages

High-containment performance ensuring operator and product safety

Quick, tool-free dismantling, including a dedicated cleaning device for efficient turnaround

Compact design for easy installation in restricted production spaces

Zero dead volume construction to prevent product loss and cross-contamination

Smooth integration with AVM split butterfly valve technology for closed, secure sampling

Whether used for routine sampling, batch verification, or quality control, the AVM high-containment sampling device provides a robust and compliant solution for modern high-potency production environmen

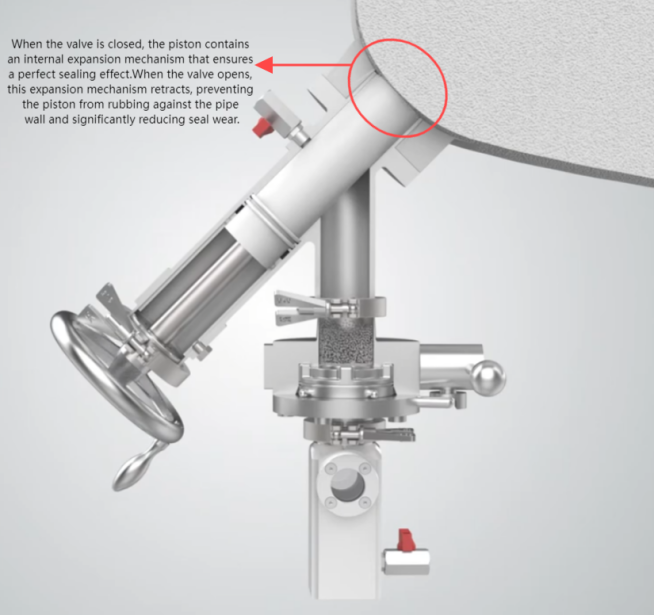

1. piston type

In closed position, sealing is formed directly by the piston on the inside wall of the valve, without the need of a gasket.The patented system inside this piston allows the PTFE to expand and insure a perfect tightness from vacuum up to 10 bar (145 psi).

The advantage of having an expendable piston inside the valve is to eliminate the need for O-rings that can be damaged during valve operation.

In this position, the piston will be flush with the connection point, leaving no dead space.

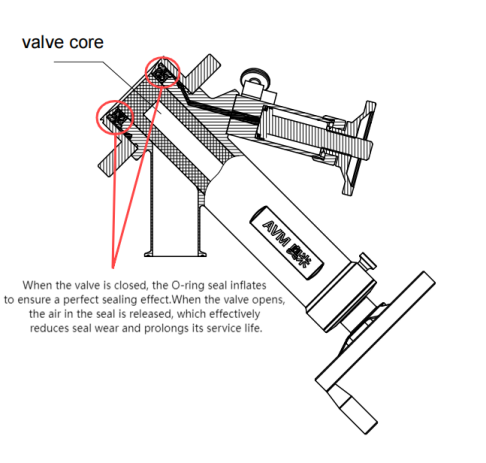

2. Inflatable seal type

Features:

Suitable for: fluids, powders, granules, and other materials.

Valve core material: PTFE+metal scraper/PEEK/PTFE/Metal,othes available.

Airbag material: Silicon/EPDM/FKM/FFKM, others available

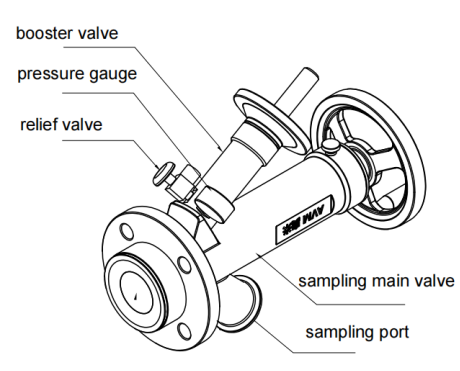

3. Accessories

❶ Split buttefly valve

AVM split butterfly valves are designed for high-containment pharmaceutical applications, achieving OEB4–OEB5. The split design ensures easy cleaning and maintenance, reliable sealing, and safe handling of potent compounds.

❷ Bottle with Tri-Clamp coupling

Sampling bottles can be customized in size and connection type to meet your specific requirements.