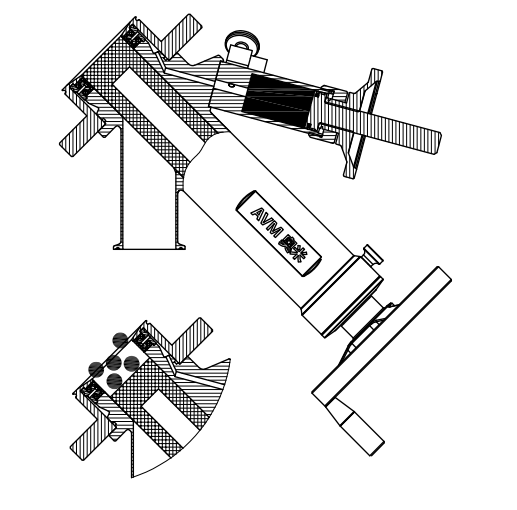

High Containment Powder Valve

Optional automation for integrated control and CIP/SIP compatibility.

- Overview

- Recommended Products

- Suitable for: fluids, powders, granules, and other materials.

- Valve core material: PTFE+metal scraper/ PEEK/PTFe/Metal, othes available.

- Airbag material: SI/EPDM/FKM/FFKM, others available.

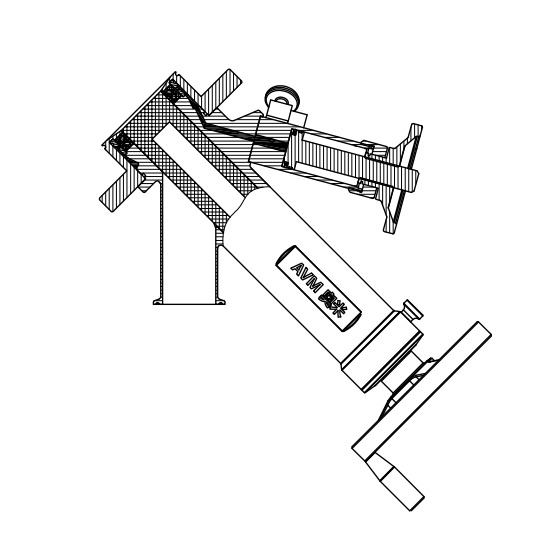

| Step 1 | Step 2 | Step 3 | Step 4 | Step 5 |

|

|

|

|

|

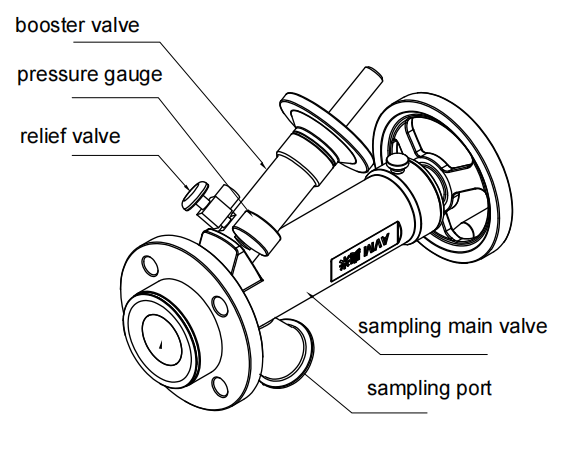

| 1.See sampling valve in closing condition |

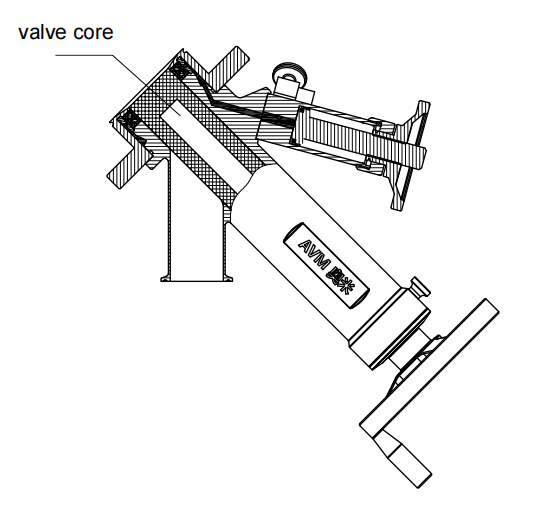

1.Open relief valve(Relief pressure of airbag)

2.Rotate booster valve handwheel, and the internal of booster

valve will be filled with air.

3.Close the relief valve.

|

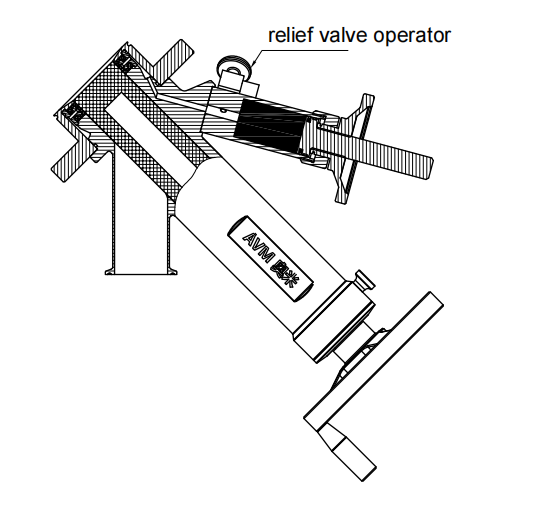

1.Rotate main valve handwheel until the valve core fully retract.

2.The material will go into the sampling port.

|

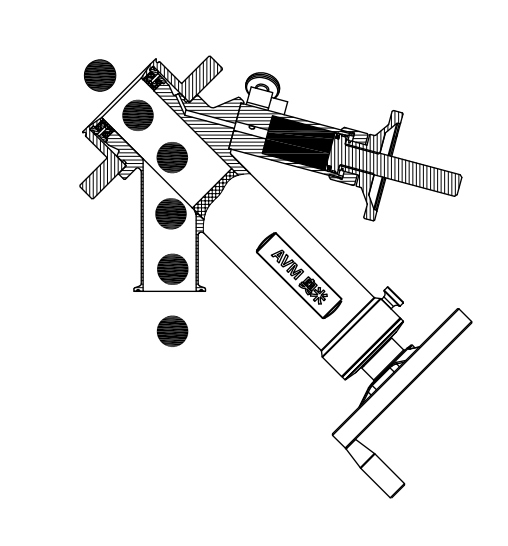

1.Rotate the main valve handwheel to push the material back

into the container.

|

1.Rotate the booster valve handwheel until the airbag gets

inflated into sealing, and observe pressure gauge at 1 bar.

2.Close the valve.

|

Our High Containment Powder Valve is specifically designed for the safe, dust-free transfer of potent or sensitive powders in pharmaceutical, biotech, and fine chemical applications.

Engineered with precision sealing and a split-valve containment concept, it ensures maximum operator safety and zero cross-contamination during charging or discharging operations.

Key features include:

High containment performance — designed to achieve containment levels down to OEB 5 / <1 µg/m³.

Smooth, crevice-free flow path for easy cleaning and minimal powder retention.

Modular design compatible with a wide range of vessels, isolators, and process equipment.

Material options: Stainless steel 316L, Hastelloy, or customized alloys for aggressive media.

Sealing materials: EPDM, FKM, or PTFE to meet FDA and USP Class VI standards.

Optional automation for integrated control and CIP/SIP compatibility.

Ideal for applications in API handling, reactor feeding, charging/blending, and packaging lines, this valve provides the highest containment integrity while maintaining operational efficiency and reliability.