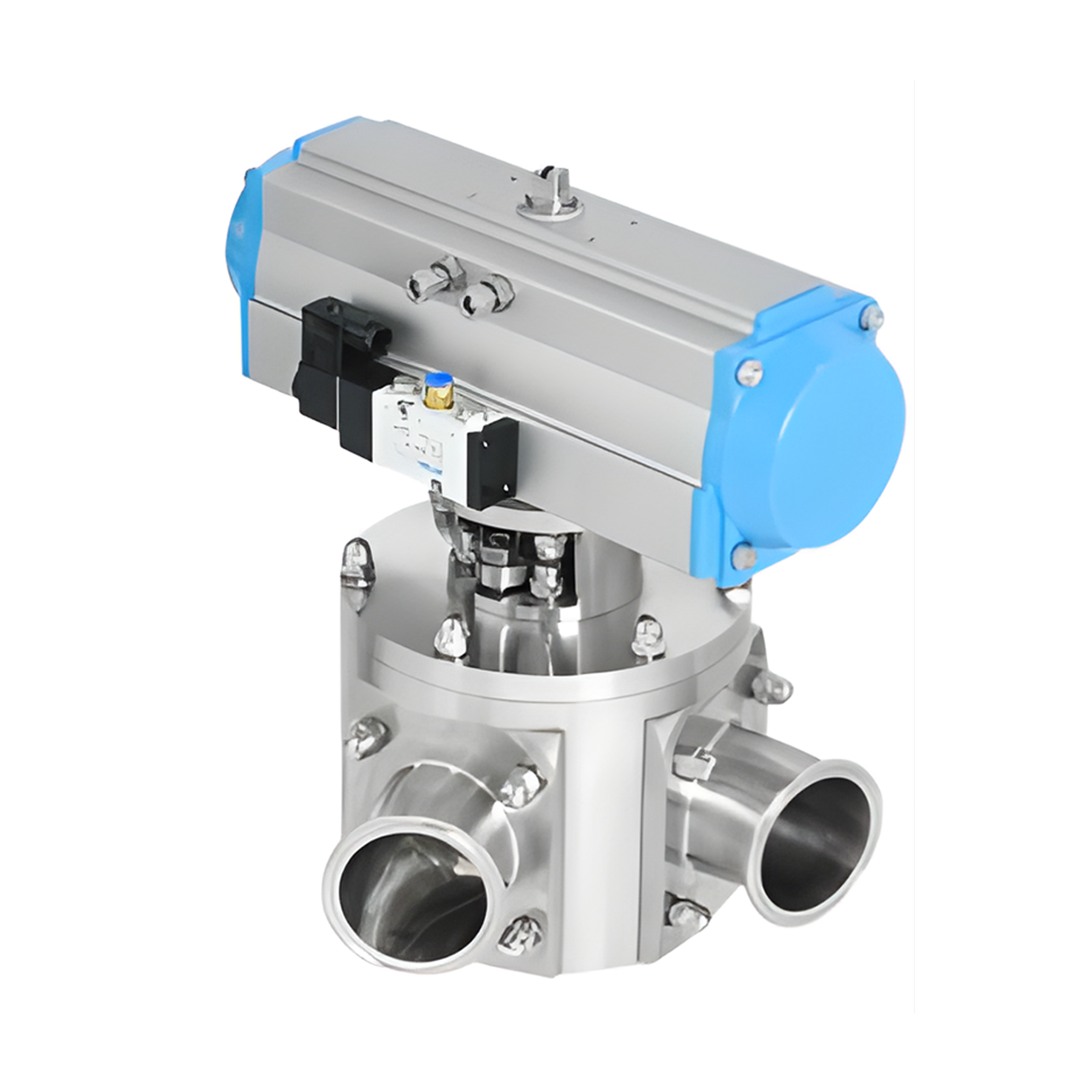

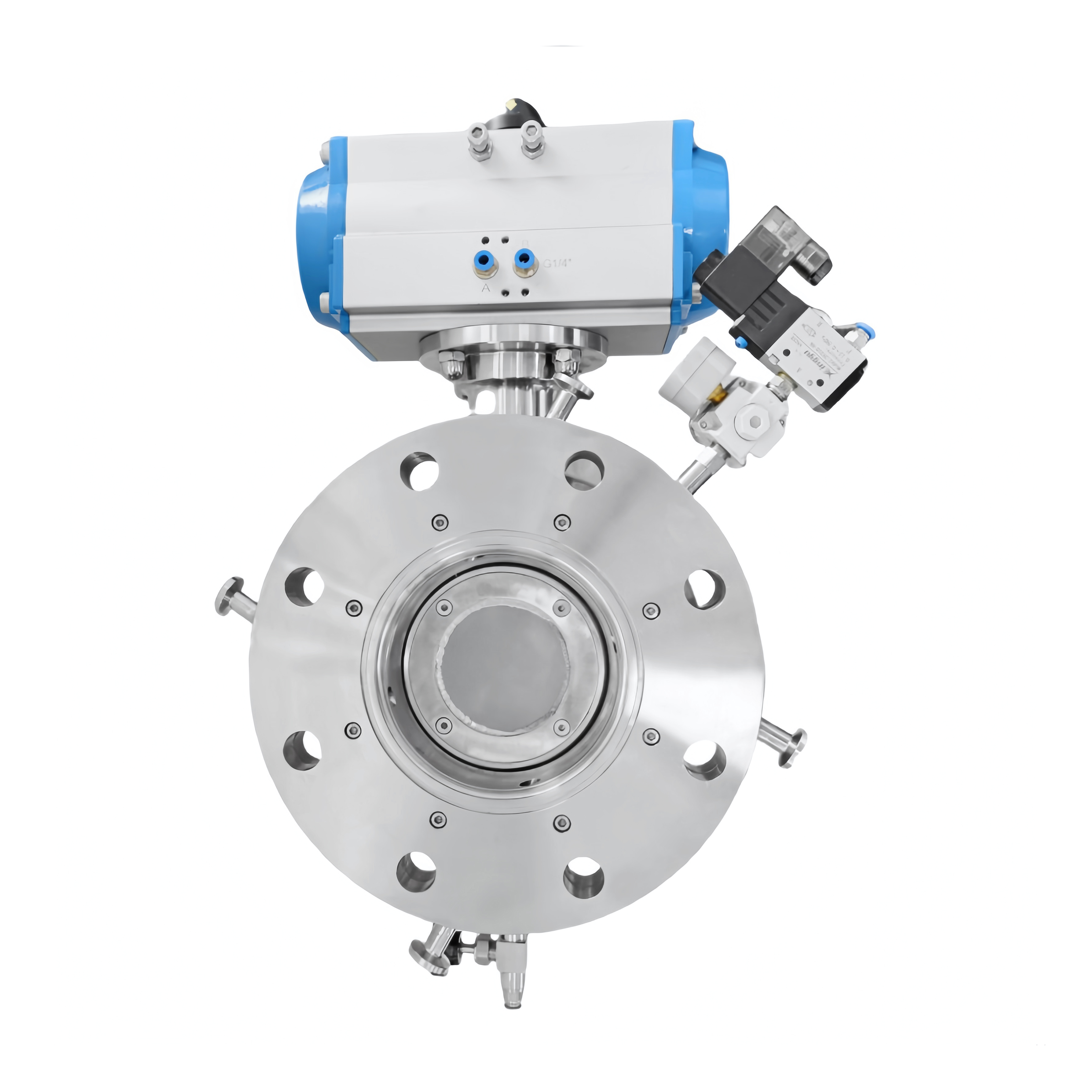

Змішувальні клапани для запобігання перехресному забрудненню під час перекачування рідин

Змішувальні клапани призначені для запобігання перехресному забрудненню між різними рідинами під час виробництва та обробки. Ці клапани мають важливе значення в таких галузях, як харчова промисловість, фармацевтика та біотехнології, де критично важливо зберігати чистоту матеріалів. Завдяки спеціальній системі подвійного ущільнення, змішувальні клапани забезпечують те, що різні рідини не змішуються, навіть якщо їх одночасно перекачують через один і той самий клапан. Ця особливість є важливою для запобігання забрудненню та забезпечення якості й безпеки кінцевого продукту.

Отримати цитату