Bomba CIP sanitaria

La serie AMB de Bombas de Anillo Líquido está especialmente diseñada para manejar productos líquidos que contienen aire o gas, lo que las hace ideales para aplicaciones en las industrias de alimentos y bebidas, farmacéutica y química. Diseñada con un enfoque en el procesamiento higiénico, esta serie de bombas asegura una transferencia eficiente y suave del producto mientras mantiene estrictos estándares sanitarios.

Fabricada con acero inoxidable de alta calidad AISI 316L (1.4404) para todas las partes en contacto con el producto, la serie AMB ofrece una excelente resistencia a la corrosión y compatibilidad con sistemas CIP (Limpieza en Place). Las componentes no en contacto con el producto, como el marco base, tuercas de la tapa y carcasa del motor, están hechas de acero inoxidable AISI 304 (1.4301). La carcasa incluye un forro amortiguador de ruido para una operación más silenciosa.

Los modelos AMB-167S, 192S y 203S cuentan con un adaptador de hierro fundido galvanizado y recubierto, proporcionando una mayor durabilidad y resistencia química.

La serie AMB ofrece una solución compacta, robusta y de bajo mantenimiento para transferir líquidos aerados con alta eficiencia y fiabilidad en entornos higiénicos.

- Descripción general

- Productos recomendados

Descripción detallada

Bomba de anillo líquido AMB de Alta Eficiencia – Diseño higiénico para transferencia de aire-líquido

La bomba de anillo líquido de la serie AMB es una solución de bomba de alto rendimiento e higiénica diseñada específicamente para transferir productos líquidos que contienen aire o gases atrapados. Diseñada para cumplir con las exigentes demandas de las industrias de alimentos, bebidas, farmacéuticos y procesamiento químico, asegura tanto un manejo suave del producto como una excepcional fiabilidad operativa.

Todas las partes en contacto con el fluido, incluyendo la carcasa de la bomba, la tapa y el impulsor, se fabrican en acero inoxidable AISI 316L (1.4404) resistente a ácidos, proporcionando una excelente resistencia a la corrosión y cumplimiento con la pureza del producto. Los elementos de sellado de EPDM son conformes con la FDA y son ideales para entornos de procesamiento sanitario.

Los componentes no en contacto con líquidos — como los tornillos de cubierta, pies de montaje, soportes y la carcasa del motor — están fabricados en acero inoxidable AISI 304 (1.4301), ofreciendo durabilidad y un acabado limpio y pulido. Para minimizar el ruido durante la operación, la carcasa del motor está equipada con un forro absorbente de sonido, mejorando el confort del operador y la acústica de la fábrica.

Los modelos más grandes, como el AMB-167S, 192S y 203S, cuentan con un robusto adaptador de hierro fundido tratado con galvanizado y recubrimiento protector, proporcionando una excelente resistencia química y un rendimiento a largo plazo.

La serie de bombas AMB es una opción ideal para sistemas integrados CIP, asegurando un rendimiento confiable en aplicaciones higiénicas y exigentes donde están presentes mezclas de aire y líquidos.

Sellado del Eje – Bombas de Anillo Líquido AMB

Los modelos AMB-167S, AMB-192S y AMB-203S están equipados con un sello mecánico de eje único para garantizar una operación segura y sin fugas. Para los modelos AMB-167S y AMB-192S, el anillo de sello fijo está hecho de acero inoxidable AISI 316L resistente a la corrosión, mientras que el anillo de sello rotativo está fabricado en carbono de alta calidad.

En contraste, el modelo AMB-203 utiliza una configuración invertida, donde el anillo de sello fijo es de carbono y el anillo de sello rotativo está hecho de acero inoxidable AISI 316L. Este diseño asegura un rendimiento de sellado confiable, compatibilidad química y mayor durabilidad bajo condiciones de proceso exigentes.

Estos sellos de precisión están optimizados para aplicaciones higiénicas y contribuyen a la larga vida útil del bomba y a sus bajos requisitos de mantenimiento.

Parámetro

| Datos Técnicos | |

| Presión de entrada máxima | 4 Bar |

| Rango de Temperatura | -20℃~+135℃(EPDM) |

Especificaciones del motor – Bombas de Anillo Líquido AMB

Las bombas de la serie AMB están equipadas con un motor de base estándar diseñado de acuerdo con los estándares métricos IEC. Los motores son de 4 polos, proporcionando una velocidad de rotación de 1500 rpm a 50 Hz, con clasificación de protección IP55 e isolación de clase F.

Voltaje y frecuencia

AMB-167S:

3~, 50 Hz: 220–240V Δ / 380–420V Y

AMB-192S & AMB-203S:

3~, 50 Hz: 380–420V Δ / 660–690V Y

Clasificaciones de Potencia del Motor (50 Hz)

AMB-167S: 4.0 kW / 4.6 kW

AMB-192S: 5.5 kW / 6.3 kW

AMB-203S: 7.5 kW / 8.6 kW

Flujo volumétrico

Aplicable para los modelos AMB-167S, AMB-192S y AMB-203S.

Opciones disponibles

Configuraciones personalizadas de voltaje y frecuencia

Motores a prueba de llamas: calificados EEx e y EEx d

Bombas disponibles sin cofre y sin patas

Bombas disponibles sin cofre

Adaptador de acero inoxidable (AISI 304) para AMB-192S y AMB-203S

Válvula de reducción de ruido

Juntas en contacto con el producto disponibles en Nitrilo (NBR) o Caucho Fluorado (FPM)

Anillo de sellado fijo con superficie de sellado de Carburo de Silicio (AMB-192S & AMB-203S)

Anillo de sellado rotativo en Carbono (AMB-192S & AMB-203S)

Información de pedido

Al hacer un pedido, por favor especifique:

Tipo de bomba

Voltaje y frecuencia

Tipos de conexión

Caudal, presión y temperatura del medio

Densidad y viscosidad del medio

Cualquier opción o personalización requerida

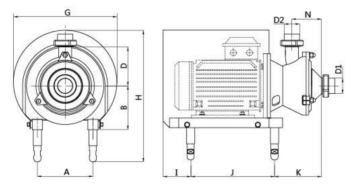

| Tamaño | 5.5KW | 7.5KW |

| A | 216 | 216 |

| B | 168 | 168 |

| D | 180 | 180 |

| GRAMO | 404 | 404 |

| H | 450 | 450 |

| H | 490 | 490 |

| I | 91 | 131 |

| J | 410 | 410 |

| K | 240 | 240 |

| Norte | 72 | 72 |

| Peso | 100 | 115 |

Bomba CIP Sanitaria AMB-192S

| Tamaño | ISO | Mensaje de texto | El |

| D1 | 63.5 | 63.5 | DN65: el número de unidades |

| D2 | 63.5 | 63.5 | DN65: el número de unidades |

Bomba CIP Sanitaria AMB-192S

| Tamaño | 4kW | 5.5KW |

| A | 190 | 216 |

| B | 147 | 168 |

| D | 163.5 | 163.5 |

| GRAMO | 355 | 404 |

| H | 400 | 450 |

| H | 440 | 490 |

| I | 95 | 91 |

| J | 330 | 410 |

| K | 255.5 | 240 |

| Norte | 72 | 72 |

| Peso | 80 | 95 |

Bomba CIP Sanitaria AMB-167S

| Tamaño | ISO | Mensaje de texto | El |

| D1 | 63.5 | 63.5 | DN65: el número de unidades |

| D2 | 63.5 | 63.5 | DN65: el número de unidades |

Bomba CIP Sanitaria AMB-167S

| Tamaño | 5.5KW | 7.5KW |

| A | 254 | 254 |

| B | 195 | 195 |

| D | 215 | 215 |

| GRAMO | 485 | 485 |

| H | 565 | 565 |

| H | 515 | 515 |

| I | 110 | 110 |

| J | 490 | 490 |

| K | 242 | 242 |

| Norte | 159 | 159 |

| Peso | 176 | 176 |

Bomba CIP Sanitaria AMB-167S

| Tamaño | ISO | Mensaje de texto | El |

| D1 | 76.2 | 76.2 | DN80 |

| D2 | 76.2 | 76.2 | DN80 |

Bomba CIP Sanitaria AMB-167S