Hygienpump CIP

AMB-seriens vätskekamrumpar är särskilt utformat för hantering av vätskeprodukter som innehåller luft eller gas, vilket gör dem ideala för användning inom livsmedels- och dryckeribranschen, läkemedelsindustrin och kemibranschen. Utformad med fokus på hygienisk bearbetning säkerställer denna pumpserie effektiv, mjuk produktöverföring samtidigt som strikta sanitära normer bibehålls.

Tillverkade av högkvalitativ rostfri stål AISI 316L (1.4404) för alla vattenexponerade delar erbjuder AMB-pumparna utmärkt korrosionsresistens och kompatibilitet med CIP (Clean-In-Place)-system. Ikompatibla komponenter som basram, lockskruvar och motorhölje är gjorda av rostfritt stål AISI 304 (1.4301). Höljet inkluderar en ljuddämpande liner för tystare drift.

Modellerna AMB-167S, 192S och 203S har en galvaniserad och beläggd järnadapter, vilket ger extra hållbarhet och kemisk resistens.

AMB-serien erbjuder en kompakt, robust och lågunderhållslösning för överföring av aerierade vätskor med hög effektivitet och pålitlighet i hygieniska miljöer.

- Översikt

- Rekommenderade Produkter

Detaljerad beskrivning

Högpresterande AMB Vätskeringpump – Hygienisk design för luft-vätskeöverföring

AMB-seriens vätskeringpump är en högpresterande, hygienisk pumplösning som utvecklats specifikt för att överföra vätskeprodukter som innehåller inhägnat luft eller gaser. Den är utformad för att möta de stränga kraven från livsmedels-, dryckes-, läkemedels- och kemiprocessindustrin och säkerställer både mjuk produktbehandling och utmärkt driftsäkerhet.

Alla vått exponerade delar, inklusive pumpkroppen, locket och rotorbladen, tillverkas av surrostmotståndande rostfritt stål AISI 316L (1.4404), vilket ger utmärkt korrosionsresistens och produktpuretetskompatibilitet. EPDM-släcksedeln är FDA-godkänd och ideal för sanitär bearbetning.

De icke våta komponenterna — som täckskruvar, monteringsfötter, stödbälten och motorhöljen — är tillverkade av rostfritt stål AISI 304 (1.4301), vilket ger hållbarhet och en ren, polerad yta. För att minska buller under drift har motorhöljet utrustats med en ljudabsorberande liner, vilket förbättrar operatörskomforten och fabriksakustiken.

Större modeller, såsom AMB-167S, 192S och 203S, har en robust gjutjärnssparkonector som behandlats med galvanisering och skyddslager, vilket ger överlägsen kemisk resistens och långsiktig prestanda.

AMB-pumpserien är en idealisk val för CIP-integrerade system, vilket säkerställer pålitlig prestanda i hygieniska och krävande tillämpningar där luft-våtormixtur finns.

Skaftepackning – AMB Vätskringpumpar

Modellerna AMB-167S, AMB-192S och AMB-203S är utrustade med en enda mekaniskt skruvbandssäkerhet för att säkerställa pålitlig och läckfri drift. För AMB-167S och AMB-192S är den stationära säkerhetsringen gjord av korrosionsmotståndskapad rostfritt stål AISI 316L, medan den rotande säkerhetsringen är gjord av högkvalitativ kol.

I motsats till AMB-203-modellen som använder en inverterad konfiguration, där den stationära säkerhetsringen är av kol, och den rotande säkerhetsringen är gjord av AISI 316L rostfritt stål. Denna design säkerställer pålitlig slutföring, kemisk kompatibilitet och förbättrad hållbarhet under krävande processförhållanden.

Dessa noggrant konstruerade säkerheter är optimerade för hygieniska tillämpningar och bidrar till pumpens långa livslängd och laga underhållsbehov.

Parameter

| Tekniska data | |

| Max inlettryck | 4 Bar |

| Temperaturintervall | -20℃~+135℃(EPDM) |

Motor Specificer – AMB Vattenringpumpar

Pumpserien AMB är utrustad med en standard fotflänsad motor, utformad enligt IEC-metriska normer. Motorerna är 4-poliga och ger en rotationshastighet på 1500 varv/min vid 50 Hz, med skyddsklass IP55 och F-klass isolering.

Spänning och frekvens

AMB-167S:

3~, 50 Hz: 220–240V Δ / 380–420V Y

AMB-192S & AMB-203S:

3~, 50 Hz: 380–420V Δ / 660–690V Y

Motorstyrkemätningar (50 Hz)

AMB-167S: 4.0 kW / 4.6 kW

AMB-192S: 5.5 kW / 6.3 kW

AMB-203S: 7.5 kW / 8.6 kW

Volymflöde

Gäller för modellerna AMB-167S, AMB-192S och AMB-203S.

Tillgängliga alternativ

Anpassade spännings- och frekvenskonfigurationer

Flambevisade motorer: EEx e och EEx d betygda

Pumpar tillgängliga utan skrov och ben

Pumpar tillgängliga utan skrov

Rostfritt stålsspets (AISI 304) för AMB-192S och AMB-203S

Ljudreduceringsventil

Produktbäddade mantlar tillgängliga i Nitril (NBR) eller Fluorierad Gummijul (FPM)

Statiskt mantlingsring med Silikarbidsmantlingsoverfläche (AMB-192S & AMB-203S)

Roterande mantlingsring i Kol (AMB-192S & AMB-203S)

Orderinformation

Vid beställning, ange följande:

Pump typ

Spänning och frekvens

Anslutningstyper

Strömning, tryck och temperatur av mediumet

Tätighet och viskositet av mediumet

Eventuella krav på tillval eller anpassningar

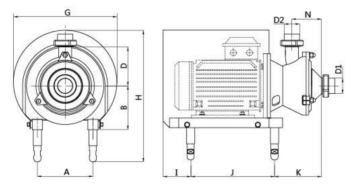

| Storlek | 5.5KW | 7.5KW |

| A | 216 | 216 |

| B | 168 | 168 |

| D | 180 | 180 |

| G | 404 | 404 |

| H | 450 | 450 |

| H | 490 | 490 |

| Jag | 91 | 131 |

| J | 410 | 410 |

| K | 240 | 240 |

| N | 72 | 72 |

| Vikt | 100 | 115 |

AMB-192S Sanitary CIP Pump

| Storlek | ISO | SMS | DIN |

| D1 | 63.5 | 63.5 | DN65 |

| D2 | 63.5 | 63.5 | DN65 |

AMB-192S Sanitary CIP Pump

| Storlek | 4kW | 5.5KW |

| A | 190 | 216 |

| B | 147 | 168 |

| D | 163.5 | 163.5 |

| G | 355 | 404 |

| H | 400 | 450 |

| H | 440 | 490 |

| Jag | 95 | 91 |

| J | 330 | 410 |

| K | 255.5 | 240 |

| N | 72 | 72 |

| Vikt | 80 | 95 |

AMB-167S Sanitary CIP Pump

| Storlek | ISO | SMS | DIN |

| D1 | 63.5 | 63.5 | DN65 |

| D2 | 63.5 | 63.5 | DN65 |

AMB-167S Sanitary CIP Pump

| Storlek | 5.5KW | 7.5KW |

| A | 254 | 254 |

| B | 195 | 195 |

| D | 215 | 215 |

| G | 485 | 485 |

| H | 565 | 565 |

| H | 515 | 515 |

| Jag | 110 | 110 |

| J | 490 | 490 |

| K | 242 | 242 |

| N | 159 | 159 |

| Vikt | 176 | 176 |

AMB-167S Sanitary CIP Pump

| Storlek | ISO | SMS | DIN |

| D1 | 76.2 | 76.2 | DN80 |

| D2 | 76.2 | 76.2 | DN80 |

AMB-167S Sanitary CIP Pump