Sanitary Manual Butterfly Valve

The sanitary butterfly valve is a compact and hygienic flow control device widely used in the food, beverage, dairy, and pharmaceutical industries. Featuring a disc that rotates within the valve body, it enables quick shut-off or regulation of flow. With options for manual or automated operation, it offers excellent sealing performance, easy cleaning (CIP/SIP compatible), and low pressure drop. It is ideal for applications requiring reliable, hygienic, and efficient fluid control.

- Overview

- Recommended Products

Detailed Description

Sanitary Butterfly Valve – Hygienic Flow Control Solution

A sanitary butterfly valve is a flow control device with a disc-shaped closing element (butterfly plate) that rotates around its own axis within the valve body to open, close, or regulate flow. Designed for hygienic applications, these valves are widely used in industries such as dairy, beverage, pharmaceutical, and food processing where clean-in-place (CIP) and sterile environments are essential.

Typically, the valve operates with a rotation angle of less than 90°, allowing for quick and efficient operation. The installation of a worm gear reducer enables self-locking and precise positioning of the disc, enhancing control and sealing reliability even under low pressure.

Key advantages of hygienic butterfly valves include:

Quick and effortless operation

Low fluid resistance and pressure drop

Simple, compact, and lightweight design

Excellent sealing performance at low pressures

Ideal for frequent operation and slurry transport

Optional manual handle or actuator for automation

In industrial applications requiring higher pressure and temperature resistance, butterfly valves are made with carbon steel bodies and metal-sealed discs, replacing traditional rubber seals. These high-performance butterfly valves are commonly used in flue gas systems, smoke ducts, and gas pipelines.

Parameter

| Technical data | ||

| Material | Contact product parts | 304L/316L(1.4307/1.4404)forged |

| non-contact product parts | 304(1.4301) | |

| Provide EN 10204 3.1B certificate | ||

| Seal material | standard | EPDM |

| option | FPM,Silicone,NBR | |

| All seal materials comply with FDA 177.2600 | ||

| Temperature | Working temperature | -20-+135℃(EPDM ) |

| Sterilization temperature | 150℃(MAX 20min) | |

| Pressure | Working pressure | 0~10bar |

| Control air pressure | 5~8bar | |

| Surface treatment | Internal surface | R≤0.8μm |

| External surface | R≤1.6μm | |

| Connection | Connection standard | welded end:DlN11850series0,2 |

| welded end:INCH pipe standard | ||

| Connection method:welding.thread、clamp,flange | ||

| Option | intelligent controller | 24V DC |

| 1/2 electromagnetism valve | ||

| Position sensor | 24V DC | |

| 2 NPN/PNP position sensor | ||

Clamp type with manual

DIN standard clamp type with manual

| Size | A | B | L | H |

| DN20 | 20 | 34 | 66 | 113.5 |

| DN25 | 26 | 50.5 | 66 | 113.5 |

| DN32 | 32 | 50.5 | 66 | 125.5 |

| DN40 | 38 | 50.5 | 68 | 132.5 |

| DN50 | 50 | 64 | 70 | 145 |

| DN65 | 66 | 91 | 72 | 163 |

| DN80 | 81 | 106 | 92 | 190 |

| DN100 | 100 | 119 | 98 | 210 |

| DN125 | 125 | 155 | 106 | 239 |

| DN150 | 150 | 183 | 120 | 288 |

SMS/3A/ISO standard clamp type with manual

| Size | A | B | L | H |

| 1” | 22.1 | 50.5 | 66 | 113.5 |

| 1.5” | 34.8 | 50.5 | 68 | 132.5 |

| 2” | 47.5 | 64 | 70 | 145 |

| 2.5” | 60.2 | 77.5 | 72 | 163 |

| 3” | 72.9 | 91 | 80 | 190 |

| 4” | 97.38 | 119 | 94 | 210 |

Welding type with manual

DIN standard welding type with manual

| Size | A | S | L | H | |

| Series1 | Series2 | ||||

| DN20 | 22 | 23 | 1.5 | 44 | 113.5 |

| DN25 | 28 | 29 | 1.5 | 44 | 113.5 |

| DN32 | 34 | 35 | 1.5 | 48 | 125.5 |

| DN40 | 40 | 41 | 1.5 | 48 | 132.5 |

| DN50 | 52 | 53 | 1.5 | 48 | 145 |

| DN65 | 70 | 2 | 50 | 163 | |

| DN80 | 85 | 2 | 56 | 190 | |

| DN100 | 104 | 2 | 60 | 210 | |

| DN125 | 129 | 2 | 70 | 239 | |

| DN150 | 154 | 2 | 80 | 288 | |

SMS/3A/ISO standard welding type with manual

| Size | A | S | L | H |

| 1” | 25.4 | 1.25 | 44 | 113.5 |

| 1.5” | 38.1 | 1.25 | 48 | 132.5 |

| 2” | 50.8 | 1.25 | 48 | 145 |

| 2.5” | 63.5 | 1.5 | 50 | 163 |

| 3” | 76.2 | 1.6 | 56 | 190 |

| 4” | 101.6 | 2 | 60 | 210 |

Threaded type with manual

DIN standard threaded type with manual

| Size | A | B | L | H |

| DN20 | 20 | RD44*1/6” | 66 | 113.5 |

| DN25 | 26 | RD52*1/6” | 66 | 113.5 |

| DN32 | 32 | RD58*1/6” | 66 | 125.5 |

| DN40 | 38 | RD65*1/6” | 68 | 132.5 |

| DN50 | 50 | RD78*1/6” | 70 | 145 |

| DN65 | 66 | RD95*1/6” | 72 | 163 |

| DN80 | 81 | RD110*1/4” | 92 | 190 |

| DN100 | 100 | RD130*1/4” | 98 | 210 |

| DN125 | 125 | RD160*1/4” | 106 | 239 |

| DN150 | 150 | RD190*1/4” | 120 | 288 |

SMS standard threaded type with manual

| Size | A | B | L | H |

| SMS25 | 22.5 | RD40*1/6” | 66 | 113.5 |

| SMS38 | 35.5 | RD60*1/6” | 68 | 132.5 |

| SMS51 | 48.5 | RD70*1/6” | 70 | 145 |

| SMS63.5 | 60.5 | RD85*1/6” | 72 | 163 |

| SMS76 | 72.9 | RD98*1/6” | 80 | 190 |

| SMS101.6 | 97.6 | RD125*1/6” | 94 | 210 |

3A standard threaded type with manual

| Size | A | B | L | H |

| 1” | 22.1 | 37.13*8TPIACME | 66 | 113.5 |

| 1.5” | 34.8 | 50.65*8TPIACME | 68 | 132.5 |

| 2” | 47.5 | 64.16*8TPIACME | 70 | 145 |

| 2.5” | 60.2 | 77.67*8TPIACME | 80 | 163 |

| 3” | 72.9 | 91.19*8TPIACME | 80 | 190 |

| 4” | 97.6 | 119.25*6TPIACME | 96 | 210 |

RJT standard threaded type with manual

| Size | A | B | L | H |

| 1” | 22.1 | 45.72*8TPIACME | 66 | 113.5 |

| 1.5” | 34.8 | 58.42*8TPIACME | 68 | 132.5 |

| 2” | 47.5 | 72.72*8TPIACME | 70 | 145 |

| 2.5” | 60.2 | 85.42*8TPIACME | 80 | 163 |

| 3” | 72.9 | 98.12*8TPIACME | 80 | 190 |

| 4” | 97.6 | 123.52*6TPIACME | 96 | 210 |

IDF standard threaded type with manual

| Size | A | B | L | H |

| 1” | 22.1 | 37.13*8TPIACME | 66 | 113.5 |

| 1.5” | 34.8 | 50.65*8TPIACME | 68 | 132.5 |

| 2” | 47.5 | 64.16*8TPIACME | 70 | 145 |

| 2.5” | 60.2 | 77.67*8TPIACME | 80 | 163 |

| 3” | 72.9 | 91.19*8TPIACME | 80 | 190 |

| 4” | 97.6 | 125.9*6TPIACME | 96 | 210 |

Three-piece type with manual

DIN standard three-piece type with manual

| Size | S | B | L | H |

| DN25 | 1.5 | 29 | 100 | 113.5 |

| DN32 | 1.5 | 35 | 100 | 125.5 |

| DN40 | 1.5 | 41 | 100 | 132.5 |

| DN50 | 1.5 | 53 | 110 | 145 |

| DN65 | 2 | 70 | 114 | 163 |

| DN80 | 2 | 85 | 130 | 190 |

| DN100 | 2 | 104 | 135 | 210 |

| DN125 | 2 | 129 | 160 | 239 |

| DN150 | 2 | 154 | 180 | 288 |

SMS/3A/ISO standard three-piece type with manual

| Size | S | B | L | H |

| 1” | 1.65 | 25.4 | 100 | 113.5 |

| 1.5” | 1.65 | 38.1 | 100 | 132.5 |

| 2” | 1.65 | 50.8 | 110 | 145 |

| 2.5” | 1.65 | 63.5 | 114 | 163 |

| 3” | 1.65 | 76.2 | 130 | 190 |

| 4” | 2.11 | 101.6 | 135 | 210 |

Three-way butterfly valve

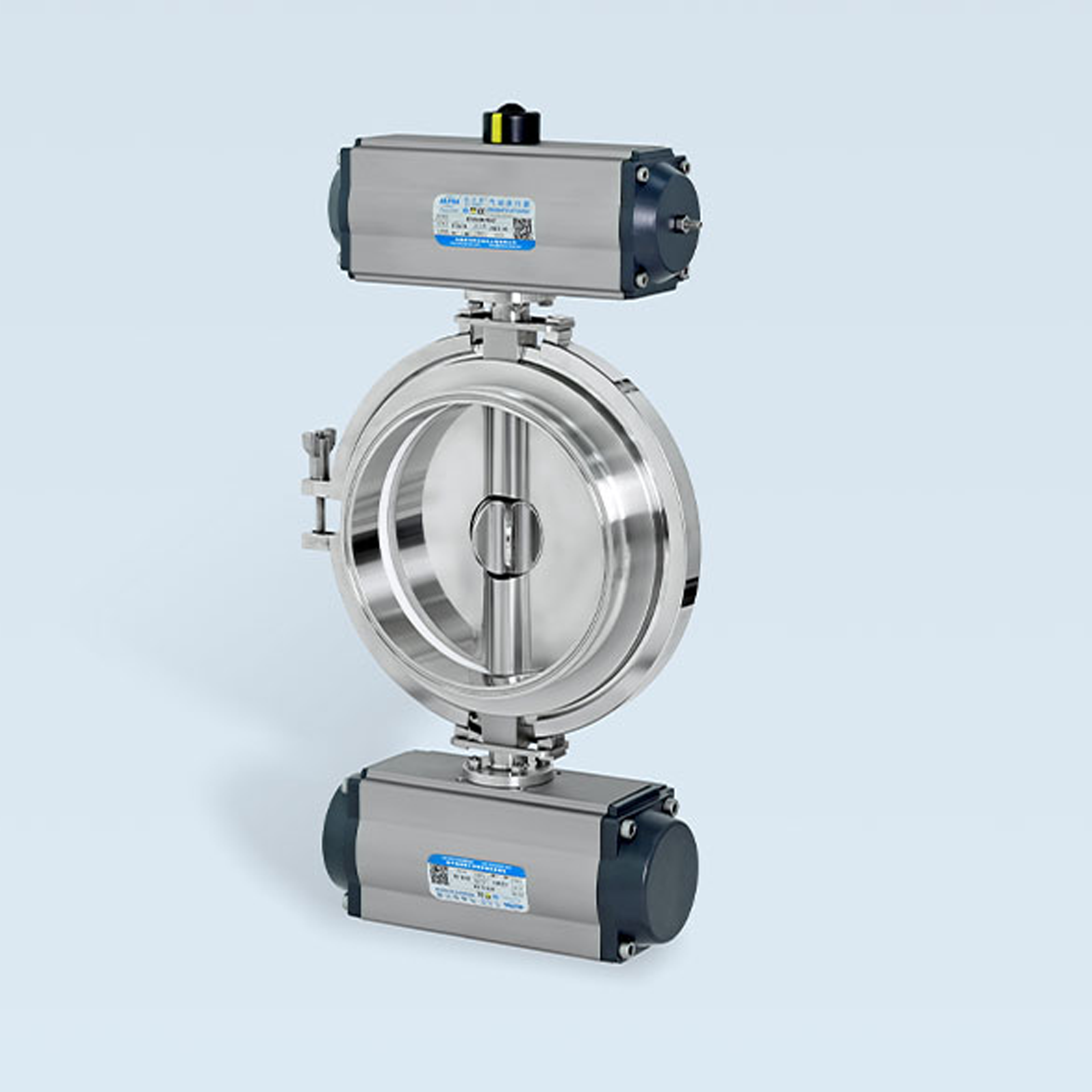

Three-Way Butterfly Valve | High-Performance Flow Control Solution

The three-way butterfly valve is a highly efficient and compact flow control solution designed for systems requiring fluid diversion or mixing. Unlike traditional valves, it enables the redirection of flow between three ports, making it ideal for complex piping systems in industries such as pharmaceutical, food & beverage, and chemical processing.

Made from high-grade stainless steel (SS316L), the valve ensures excellent corrosion resistance, sanitary operation, and durability. Its precision-engineered disc and seat provide a tight seal, supporting both on/off and throttling functions. The valve can be actuated manually or pneumatically for optimized automation and process control.

This three-way butterfly valve is your ideal choice for hygienic applications demanding reliable flow control, space-saving installation, and easy maintenance.