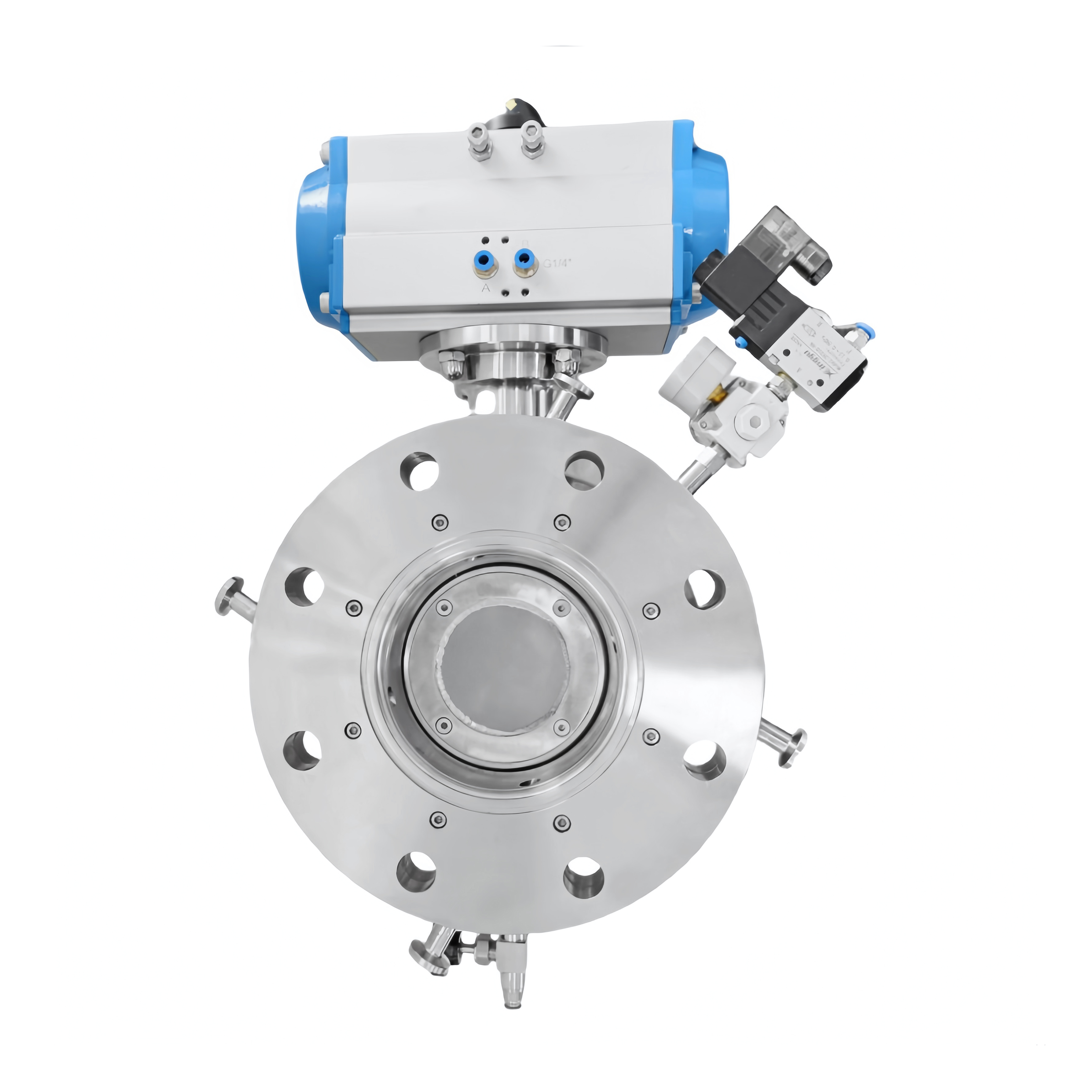

Precise Flow Control with Diaphragm Valves

Our Diaphragm Valve uses a diaphragm to control the flow of fluids and gases, isolating the fluid from the valve’s driving parts. This design is especially useful in industries requiring high purity and cleanliness, such as pharmaceuticals, food processing, and electronics. Simple in construction with excellent sealing properties, this valve offers reliable performance in controlling various liquids, gases, or corrosive media, while being easy to maintain and repair.

Get A Quote