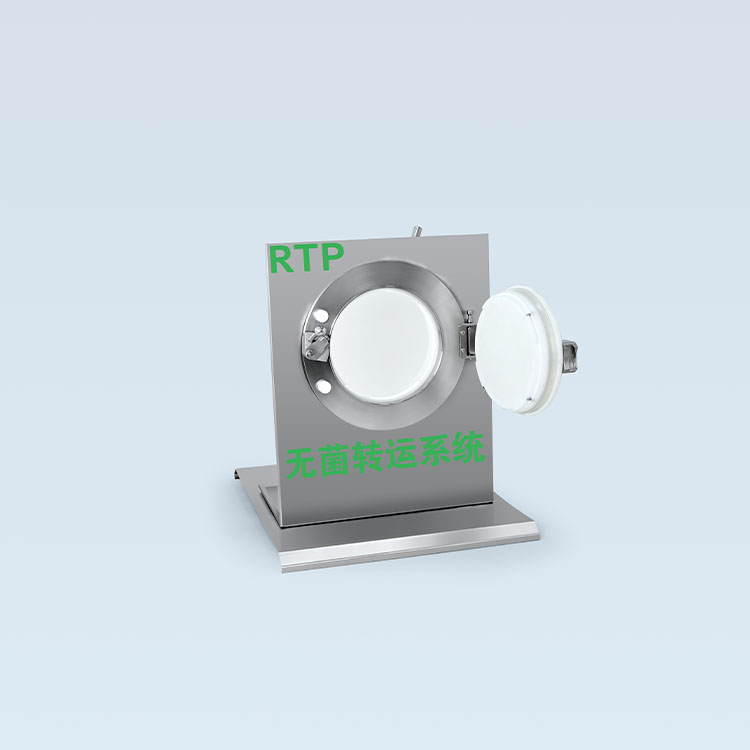

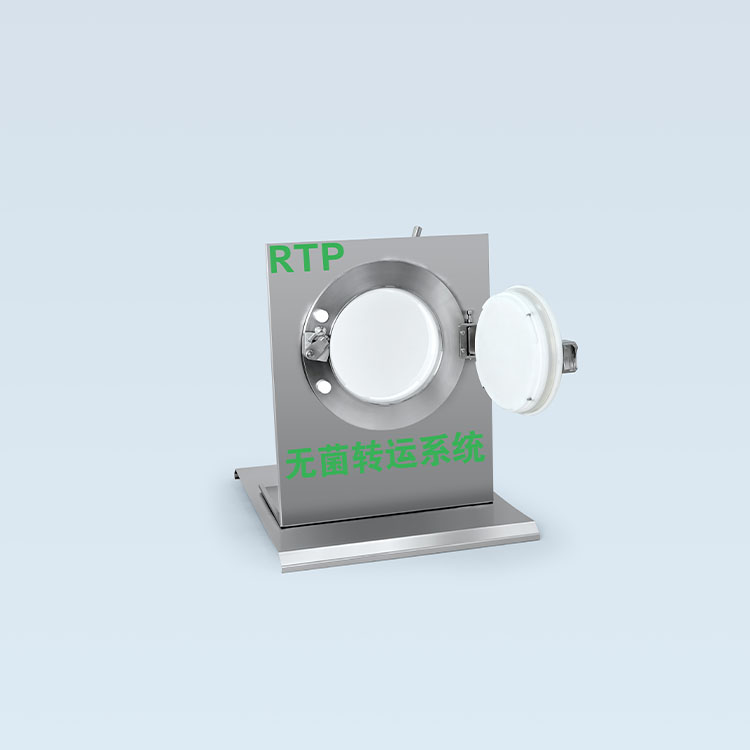

Rapid Transfer Port for Critical Applications in High-Sterility Environments

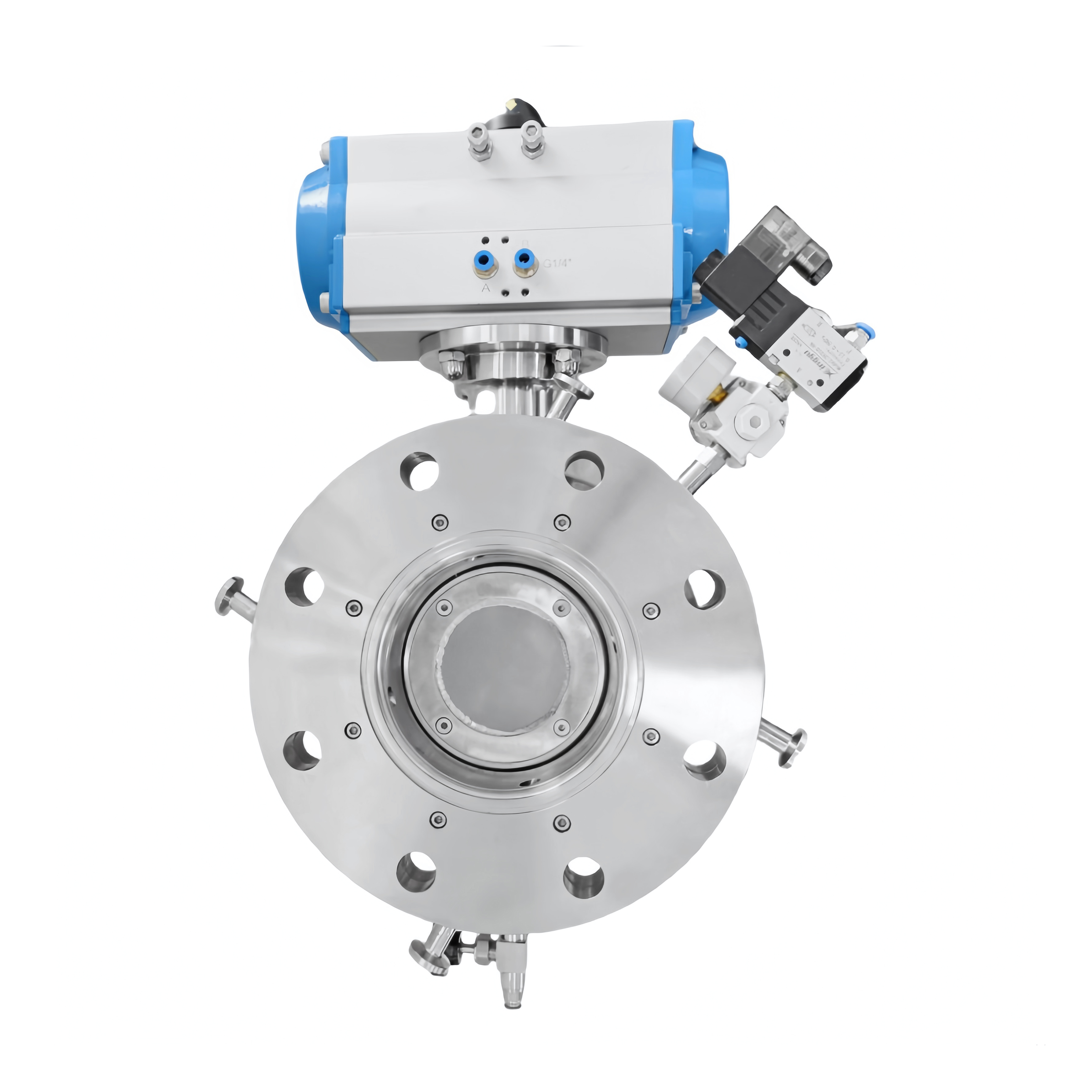

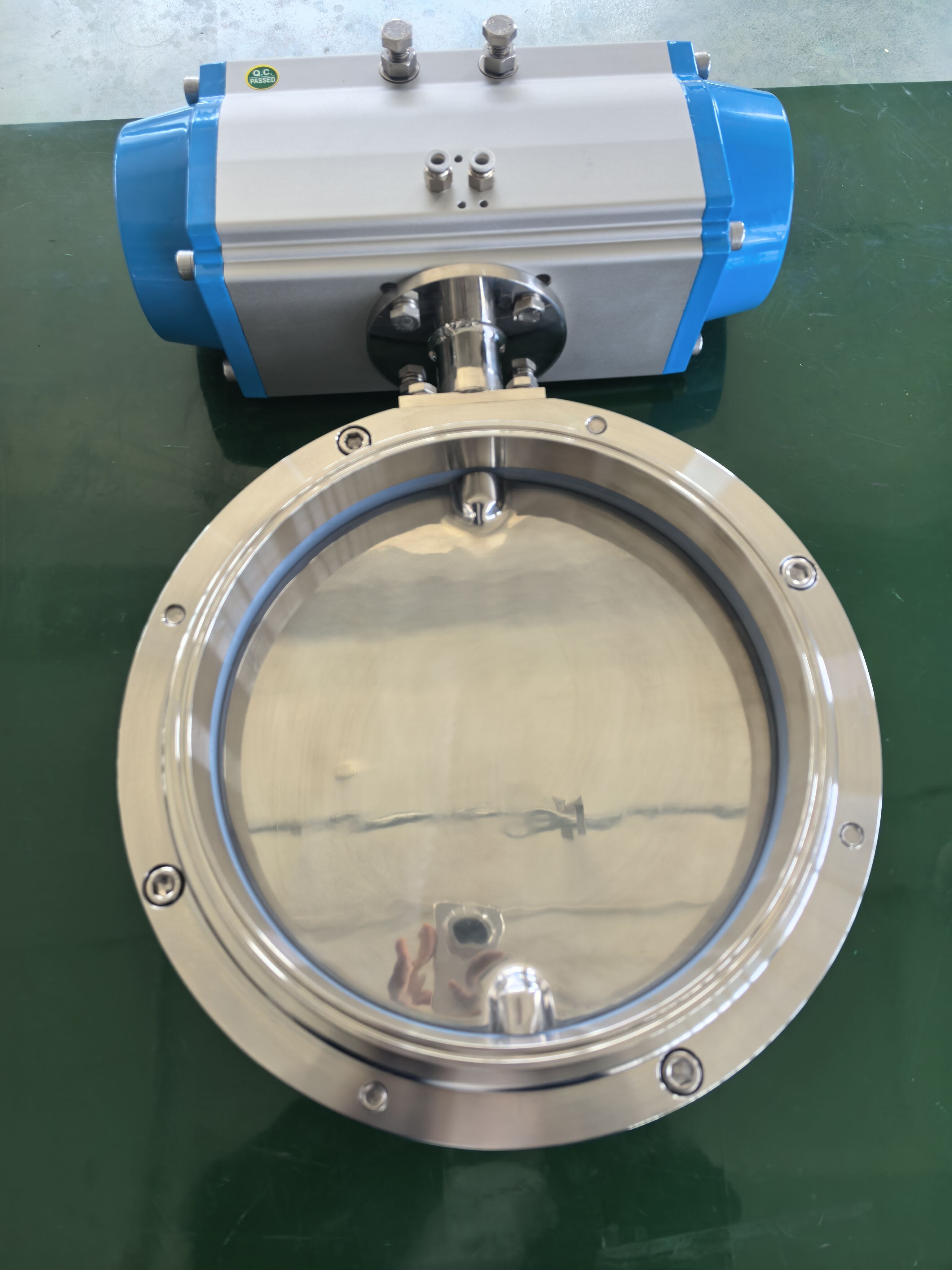

Our Rapid Transfer Port ensures the secure and efficient transfer of materials in high-cleanliness environments, like life sciences and pharmaceuticals. With a dual-door transmission system, it maintains sterile conditions even during two-way transfers in critical areas. The port's design includes ergonomic handles that break the Beta container seal with minimal effort, reducing operator strain. Additionally, the smooth, lockable surface design, and interchangeable Beta installation base help maintain an uncontaminated environment. Perfect for industries requiring sterile, high-purity handling.

Get A Quote