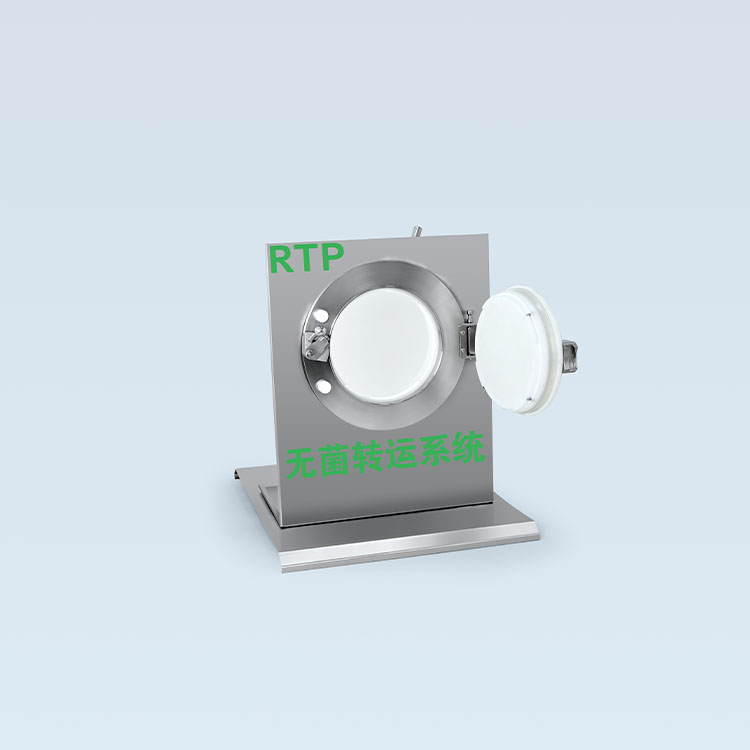

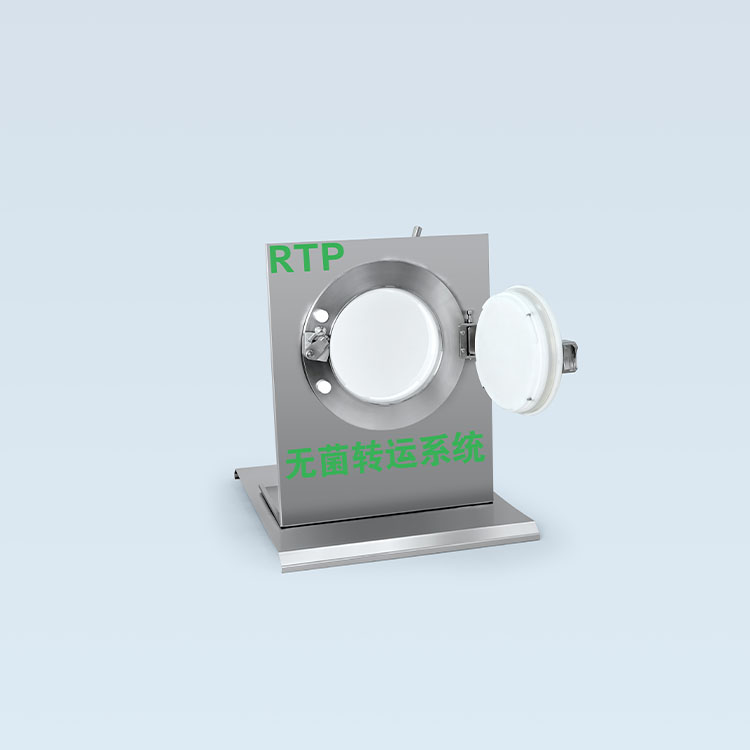

Efficient and Safe Material Transfer with Rapid Transfer Ports in Sterile Environments

Rapid Transfer Ports (RTP) play an essential role in ensuring safe and efficient transfers of materials in environments where sterility and contamination prevention are critical, such as in pharmaceutical, biotech, and life sciences industries. Designed with a double-door system, these ports ensure that no contamination occurs while transferring substances between sterile zones. The innovative handle design allows for minimal effort to break the seal of beta containers, which improves safety for operators by reducing physical strain. Additionally, the ports feature a streamlined interlocking system and smooth, easy-to-clean surfaces, making them ideal for maintaining the sterility of materials in critical applications. Whether handling toxic substances or maintaining aseptic conditions, RTPs offer a reliable solution.

Get A Quote