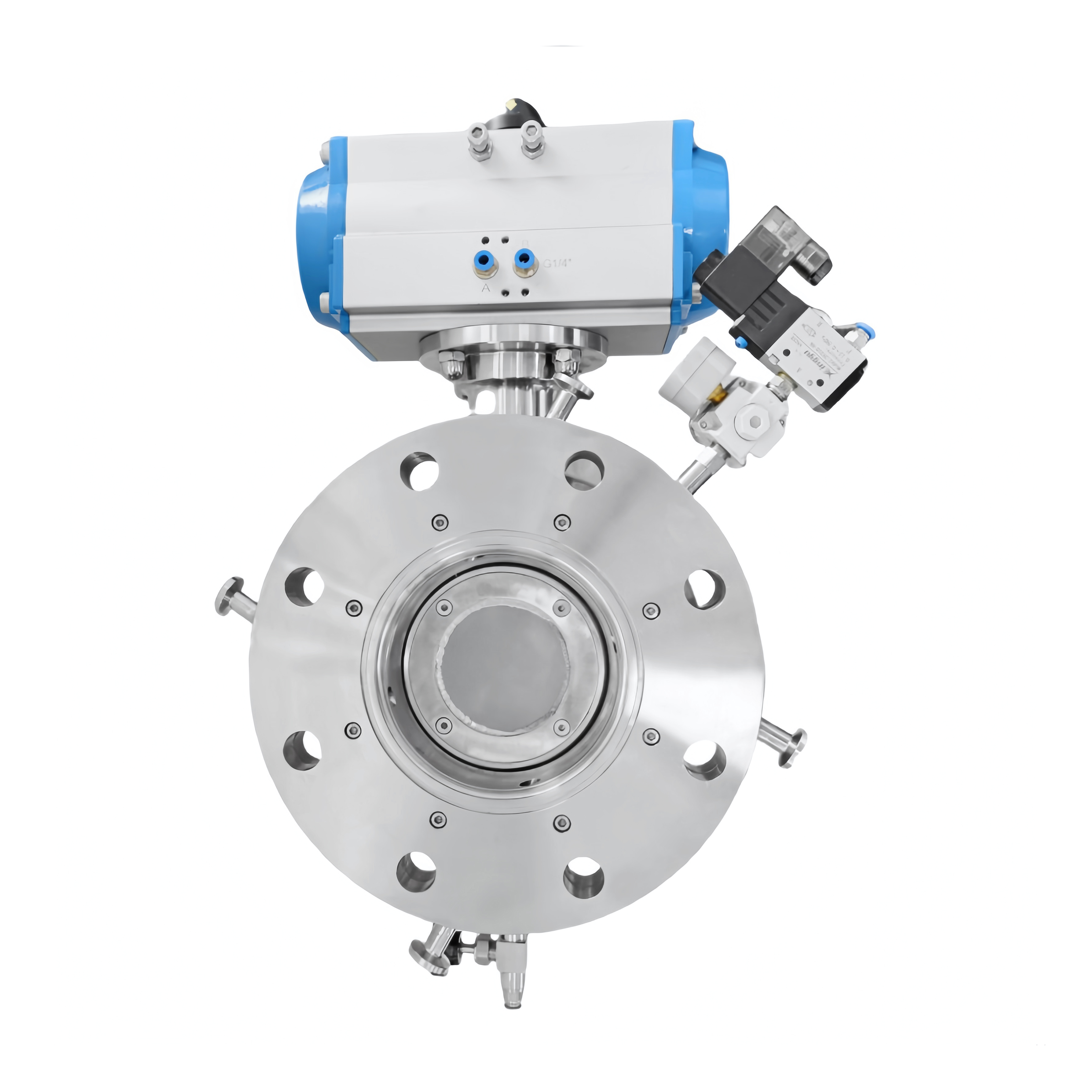

Superior Sealing with Inflatable Seals

The Inflatable Seal is designed for use in applications where high sealing performance is required, such as in the food, pharmaceutical, and chemical industries. It expands when inflated to form a tight seal between two surfaces, and contracts when deflated for easy insertion and removal. It is used in a variety of industries, including food sterilizers, packaging, textile, and metal processing, ensuring effective sealing in dynamic environments without causing damage or wear to components.

Get A Quote