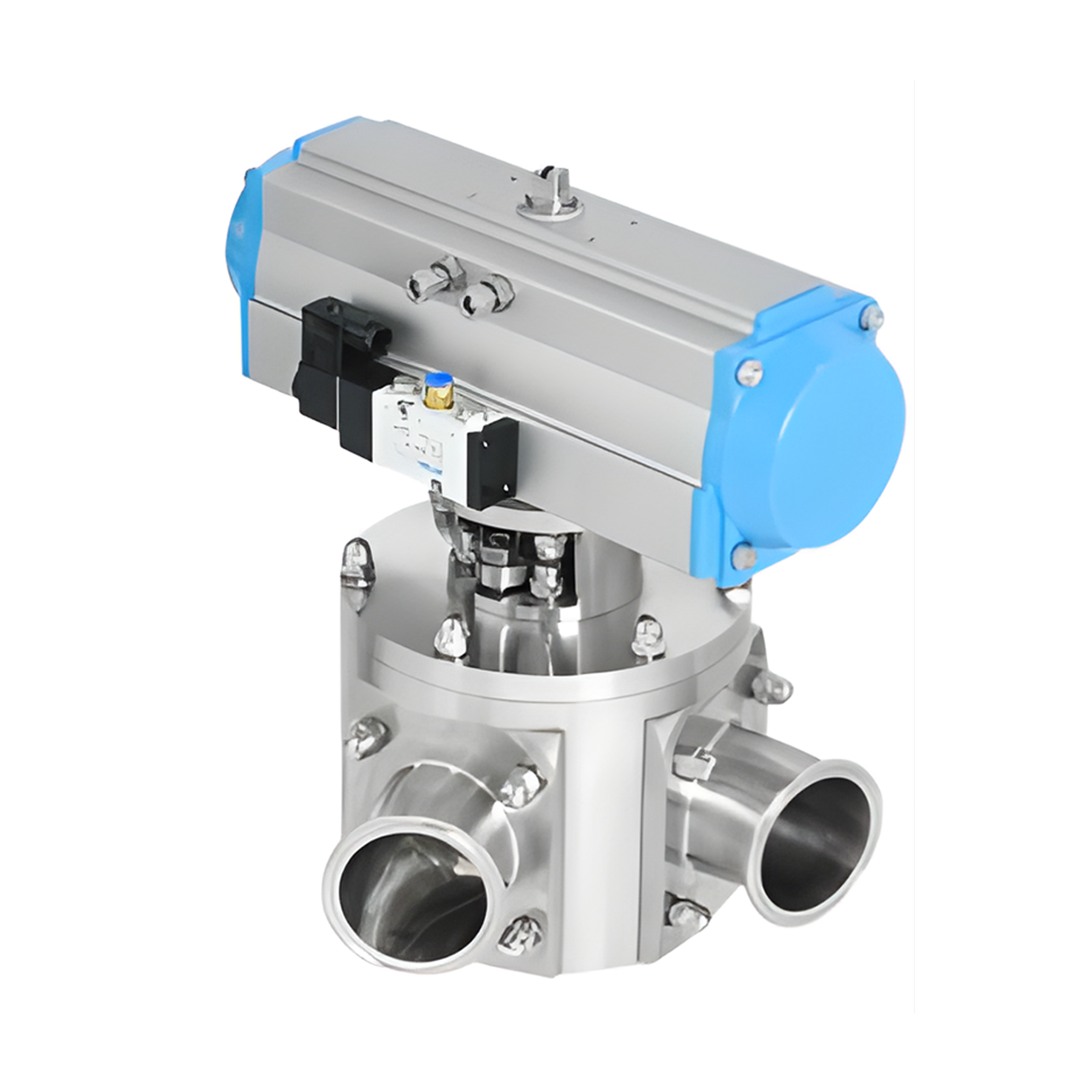

Pneumatic Control Valves: Precision Automation for Critical Processes

AVM's Pneumatic Control Valves combine rapid response with precise flow regulation, ideal for automated systems in pharma, petrochemical, and power industries. Featuring linear (single-seat, cage valves) and quarter-turn (ball, butterfly) designs, they enable accurate control of flow, pressure, or level. Manufactured to DIN, ISO, and 3A standards with ISO 9001 certification, these valves use Japanese Mazak CNC machining for tight tolerances, ensuring reliable performance in high-demand environments.