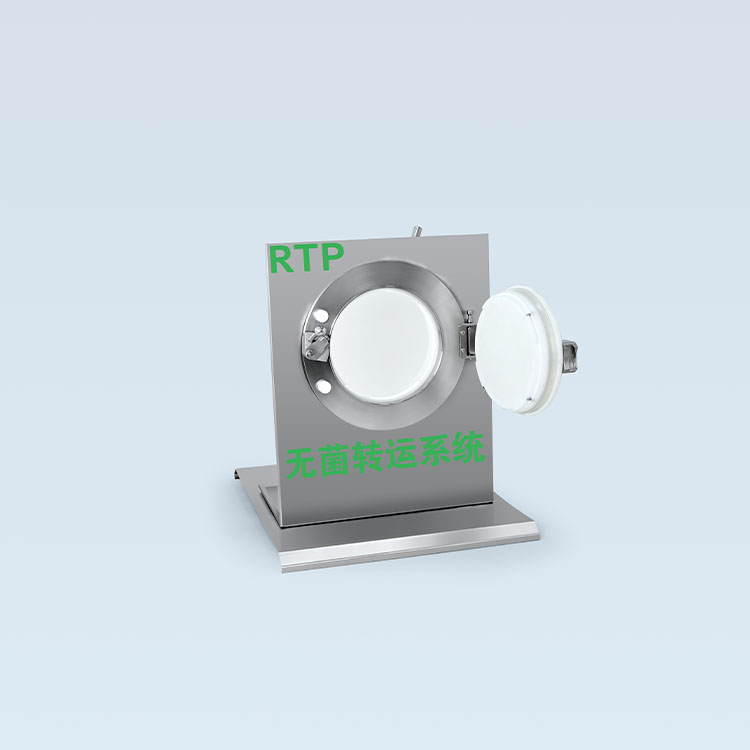

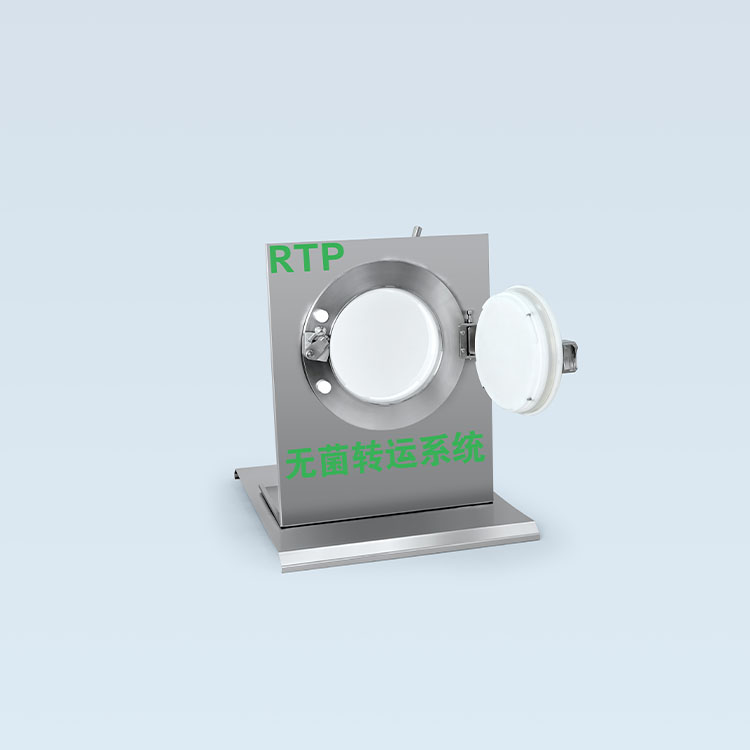

Rapid Transfer Port for Safe, Efficient Sterile Material Transfer in Sensitive Environments

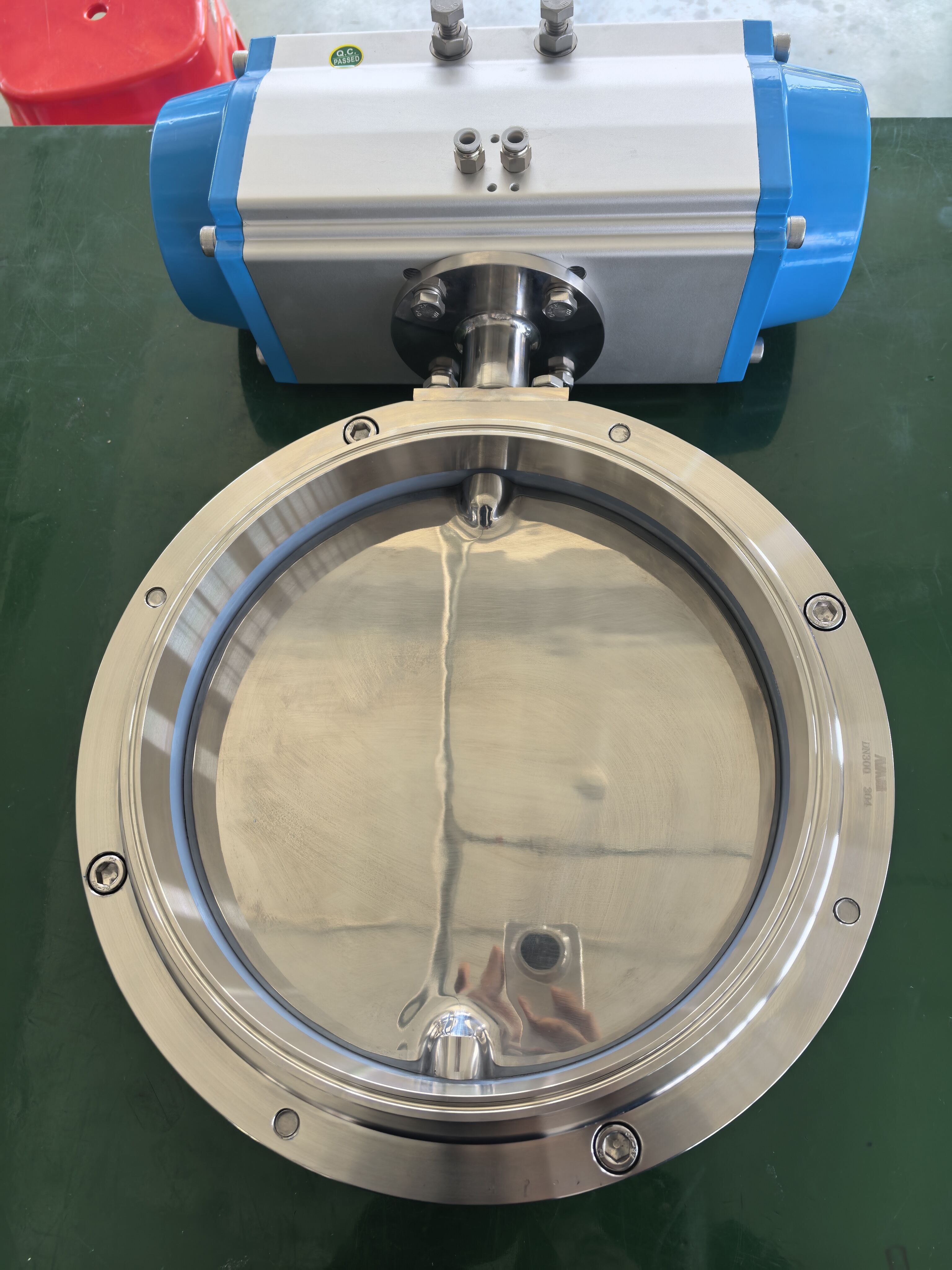

Our Rapid Transfer Port is designed for high-efficiency, secure material transfer in critical environments, particularly where cleanliness is paramount, such as life sciences. It utilizes a double-door transfer system, ensuring no breach in sterile or toxic environments. The design includes an innovative handle that breaks the Beta container seal with minimal effort, reducing operator strain and improving safety. This port is ideal for industries that require rigorous sterility and safety protocols, such as pharmaceuticals and biotechnology.

Get A Quote