Why Powder Clogging Occurs: Bridging, Ratholing, and Flow Failure

Root Causes: Cohesion, Aeration, and Particle Geometry

When powder doesn't flow properly, it usually comes down to three main issues: how particles stick together, trapped air problems, and the actual shape of those particles. Particle cohesion happens when forces between individual grains get strong enough to beat gravity's pull, making them form clumps instead of flowing smoothly. Air pockets inside the powder mess with the overall density, which can cause all sorts of flow issues from unexpected fluid movement to sudden loss of air support. The way particles look matters too. Irregular shapes such as flakes or tree-like dendrites tend to lock together mechanically, while very small particles under 50 microns have so much surface area relative to their weight that they become extra sticky. When there's more than 5% moisture present, capillary bridges start forming throughout the powder bed, effectively turning what should be flowing material into something resembling a solid block. These combined effects lead to dead spots in processing equipment where material gets stuck, creating common problems like bridging where an arch blocks the exit point, or ratholing where everything flows through just one central path and leaves material piled up around the edges.

Impact on Process Reliability and Downtime

When flow problems occur in production lines, they hit both efficiency and bottom line pretty hard. Manual unclogging stops everything dead in its tracks for several hours at a time, and companies are looking at around $10k loss each time this happens. What's worse, inconsistent product discharge creates all sorts of headaches including variable batches, wasted raw materials, and reduced yields somewhere between 15% to maybe even 30%. For those dealing with abrasive substances, regular clogs mean wearing down equipment faster than normal, which pushes maintenance bills up by roughly 40% annually. Take hygroscopic stuff like APIs or cement for instance these materials grab onto moisture and turn into rock solid blockages that force complete system shutdowns just to clean them out. A recent 2023 study on bulk material handling found that plants dealing with flow issues once a week saw their overall equipment effectiveness drop by about 22%, so it really makes sense to invest in preventive measures if we want our systems running reliably day after day.

Powder Valve Engineering Solutions: Full-Bore Design and Elastic Sealing

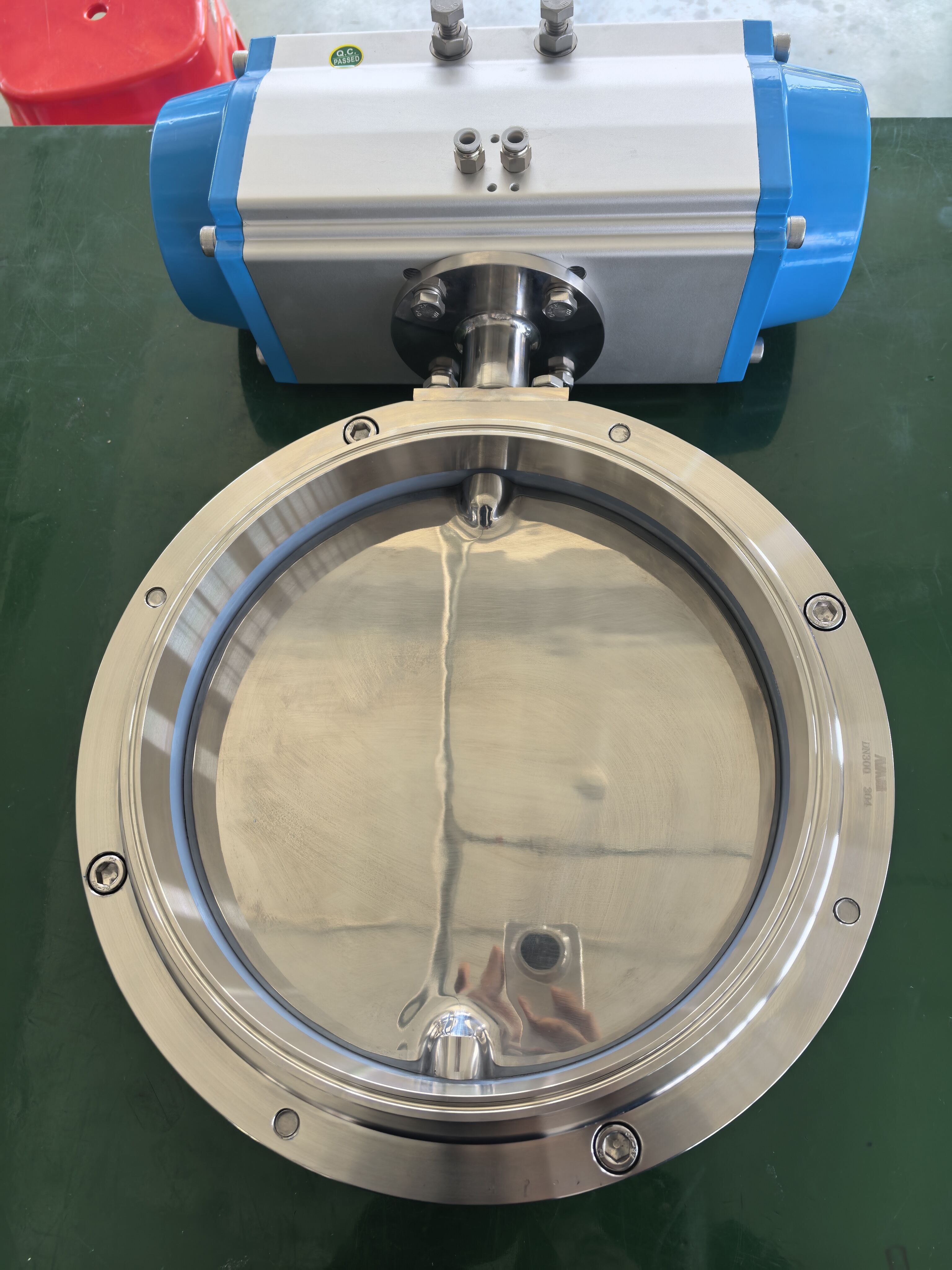

Full-Bore Flow Path Eliminates Dead Zones and Promotes Gravity-Assisted Discharge

Full bore powder valves have this great advantage of matching the pipeline diameter exactly, so there are no hidden spots where powder gets stuck and builds up over time. The design works really well with gravity, which helps prevent those annoying problems like bridging and ratholing that plague regular valves with restrictions. When the valve maintains the same cross section throughout, it cuts down on flow resistance significantly compared to smaller port designs. Some tests show reductions of around 90%, which makes a huge difference in keeping operations running smoothly. Because these valves offer such an open path, materials like silica and cement that tend to stick together or absorb moisture can flow out completely without needing extra equipment for vibration or air assistance. This saves both time and money in maintenance costs.

Rubber Sleeve Mechanism: Pinch-Actuated Constriction and Self-Cleaning Action

Advanced powder valves feature an elastomeric sleeve that creates a seal through radial compression, adapting well to different particle sizes. When released, the sleeve bounces back elastically, creating what's called a "snap-back" effect which helps clear leftover material off the sealing surface. This cleaning mechanism really shines when dealing with sticky substances such as those found in pharmaceutical manufacturing, where residue buildup often causes valves to fail prematurely. Compared to traditional rigid seat designs, these flexible sleeves handle small amounts of wear and tear much better without leaking, which means they last longer between maintenance checks. Some field tests indicate maintenance needs drop somewhere around three to fivefold in bulk material operations, though actual results can vary depending on specific conditions and materials handled.

Powder Valve Performance Validation: Abrasive, Sticky, and Hygroscopic Powders

Getting the valves right matters a lot when dealing with tricky powders like silica, cement, and those pharmaceutical ingredients we call APIs. These materials are real troublemakers for flow consistency. The abrasive ones just eat away at parts over time, while sticky stuff tends to cling everywhere it touches. And don't even get me started on hygroscopic materials that soak up moisture from the air and turn into hard clumps nobody wants to deal with. Running tests under all these harsh conditions isn't optional if facilities want their systems to last. Nobody likes unexpected shutdowns, especially since they cost around seven hundred forty thousand dollars each year per plant according to industry reports from 2023. That kind of money adds up fast.

Case Evidence: Silica, Cement, and API Powder Transfer with Zero Clog Incidents

Real-world applications confirm the effectiveness of engineered powder valves:

- Silica handling: Valves with wear-resistant liners enabled uninterrupted transfer for 12 months, with no clogs despite the material’s high abrasiveness.

- Cement operations: Gravity-assisted full-bore valves eliminated ratholing, overcoming cement’s natural cohesion and achieving 99.8% operational uptime.

- API transfer: In pharmaceutical settings, self-cleaning rubber sleeves prevented moisture-induced caking, maintaining batch consistency with zero blockages over 18 months.

These results illustrate how purpose-built valves resolve material-specific flow issues, cutting maintenance costs by 45% compared to conventional valve types.

Selecting the Right Powder Valve: Key Criteria Beyond Traditional Valve Types

Selecting the proper powder valve means looking past basic specs such as pressure ratings. Materials matter a lot here. The elastomers and metal parts need to stand up against wear from things like silica particles or resist breaking down when exposed to moisture sensitive chemicals. When it comes to how well powders flow through the system, design plays a big role. Full bore valves are great because they get rid of those pesky dead spots where material can get stuck, which is particularly important with powders that tend to clump together, think cement for instance. What kind of environment the valve operates in will dictate other requirements too. Food processing plants need valves that meet strict hygiene standards while facilities handling explosive dust need valves that comply with ATEX regulations. Maintenance factors impact bottom line costs significantly. Studies show that valves with self cleaning rubber sleeves cut downtime roughly 40% better than traditional mechanical seals when dealing with bulk materials. Always test valve performance with actual powders used in production. Something that works perfectly with loose flowing granules might completely fail when faced with sticky adhesive materials. Keep an eye on overall lifecycle expenses since unexpected stoppages cost industries around $740k each year according to latest industry reports.

FAQs

- What causes powder clogging in industrial systems? Powder clogging is typically caused by particle cohesion, trapped air pockets, and irregular particle shapes that prevent smooth flow.

- How do flow failures impact process reliability? Flow failures lead to inefficiency, frequent system downtimes, and financial losses due to manual unclogging, inconsistent product batches, and increased equipment wear.

- What are the benefits of full-bore powder valves? Full-bore powder valves align with pipeline diameter to eliminate dead zones, reduce flow resistance by 90%, and help prevent problems like bridging and ratholing.

- Why are elastomeric sleeves advantageous in valve design? Elastomeric sleeves offer pinch-actuated sealing and self-cleaning action, which handle residue effectively and prolong valve lifetime compared to traditional designs.

- How do engineered valves improve handling of challenging powders? Engineered valves adapt to various particle types, ensuring uninterrupted transfer and minimizing maintenance needs while maintaining operational uptime.

- What factors should be considered in selecting powder valves? Consider material durability, flow consistency, operational environment standards, and maintenance implications when selecting the right powder valve.

Table of Contents

- Why Powder Clogging Occurs: Bridging, Ratholing, and Flow Failure

- Powder Valve Engineering Solutions: Full-Bore Design and Elastic Sealing

- Powder Valve Performance Validation: Abrasive, Sticky, and Hygroscopic Powders

- Selecting the Right Powder Valve: Key Criteria Beyond Traditional Valve Types

- FAQs