Matching Rotary Valve Design to Powder Flow Behavior

Angle of Repose, Flow Function Number (FF), and Bridging Risk Assessment

When looking at how powders flow, two key factors stand out for predicting bridging problems in rotary valves: the angle of repose and what's called the Flow Function Number (FF). Most materials that have an angle of repose above 50 degrees tend to get stuck in regular rotors. That means engineers need to adjust things like adding offset pockets or creating tapered inlets just to keep the material flowing properly through the system. For powders with an FF below 2, which basically means they stick together a lot, there's a much bigger chance of bridging issues. Studies on bulk solid handling show these sticky powders bridge about 70% more frequently compared to those that flow freely. Getting around this problem requires careful attention to rotor-to-housing clearances. Fine powders that clump together need very tight spaces between 0.1 and 0.3 mm, while coarser materials can handle gaps from 1 to 3 mm. Good designs usually incorporate special pocket shapes that break up particles sticking together, along with seals that hold up under pressure tests showing no more than 4% leakage when put through their paces.

Cohesiveness Impact on Rotor Pocket Fill Efficiency and Discharge Consistency

When dealing with cohesive powders, we often see problems with fill efficiency and discharge uniformity across different applications. Take titanium dioxide as a case study it has a Carr Index over 35 and can reach around 92% pocket fill when using shallow pocket rotors. That's quite a jump from the typical 65% seen with older rotor designs. Why? Because these new rotors reduce how particles stick to walls and create better angles for material to exit properly. Operators find that keeping speeds under 20 RPM really helps minimize those annoying discharge pulses. At these lower speeds, there's less chance of material compacting inside pockets while still maintaining pretty good accuracy within plus or minus 3%. What about surface finish? This matters a lot too. Rotors that have been electro polished down to Ra values under 0.4 microns actually reduce cohesive buildup by about 40% compared to regular machine finishes. Manufacturers working on continuous processes notice this makes a real difference in getting consistent results from one batch to the next.

Mitigating Abrasive Wear in High-Hardness Powder Applications

Materials like alumina or silicon carbide that have a Mohs hardness rating of 5 or higher cause serious problems for valves because they cut into surfaces and create fatigue from repeated impacts. When looking at particle shape matters a lot too angular grains can make erosion issues worse by around 30 to maybe even 50 percent compared to round ones. These sharp corners focus all the damage right where it hurts most on the front edges of rotor vanes and near the discharge areas of the housing. What we actually see are these crescent shaped marks forming on metal parts over time. As this continues, the seals start to fail and the whole system becomes less accurate in how much material it processes.

Mohs Hardness, Particle Shape, and Erosion Patterns on Rotor Vanes and Housing

Hardness dictates failure mode: powders above Mohs 7 can induce brittle fracture in carbon steel components within months. Sharp-edged quartz (Mohs 7), for instance, erodes housings three times faster than rounded garnet of equivalent hardness. Erosion mapping identifies three critical zones:

- Vane tips, where impact velocity peaks at 15–25 m/s

- Lower housing quadrants, subject to sliding abrasion from accumulated fines

- Radial clearances, which widen as embedded particles abrade mating surfaces

Wear-Resistant Solutions: Hardened Alloys, Ceramic Linings, and Optimized Vane Geometry

Effective wear mitigation relies on integrated material and geometric strategies:

- Hardened alloys: Chromium carbide overlays (58–65 HRC) resist micro-cutting in high-silica applications

- Ceramic linings: Alumina or zirconia inserts deliver 90% wear reduction for Mohs 9+ powders

-

Geometric optimization:

- Rounded vane profiles deflect particle impacts

- Minimum tip thickness of 8 mm delays edge failure

- Converging clearance gaps reduce particle entrapment

Thermal spray coatings extend service life by 400% in cement clinker handling, while optimized rotor geometry extends replacement intervals from quarterly to biennial—without sacrificing throughput or sealing.

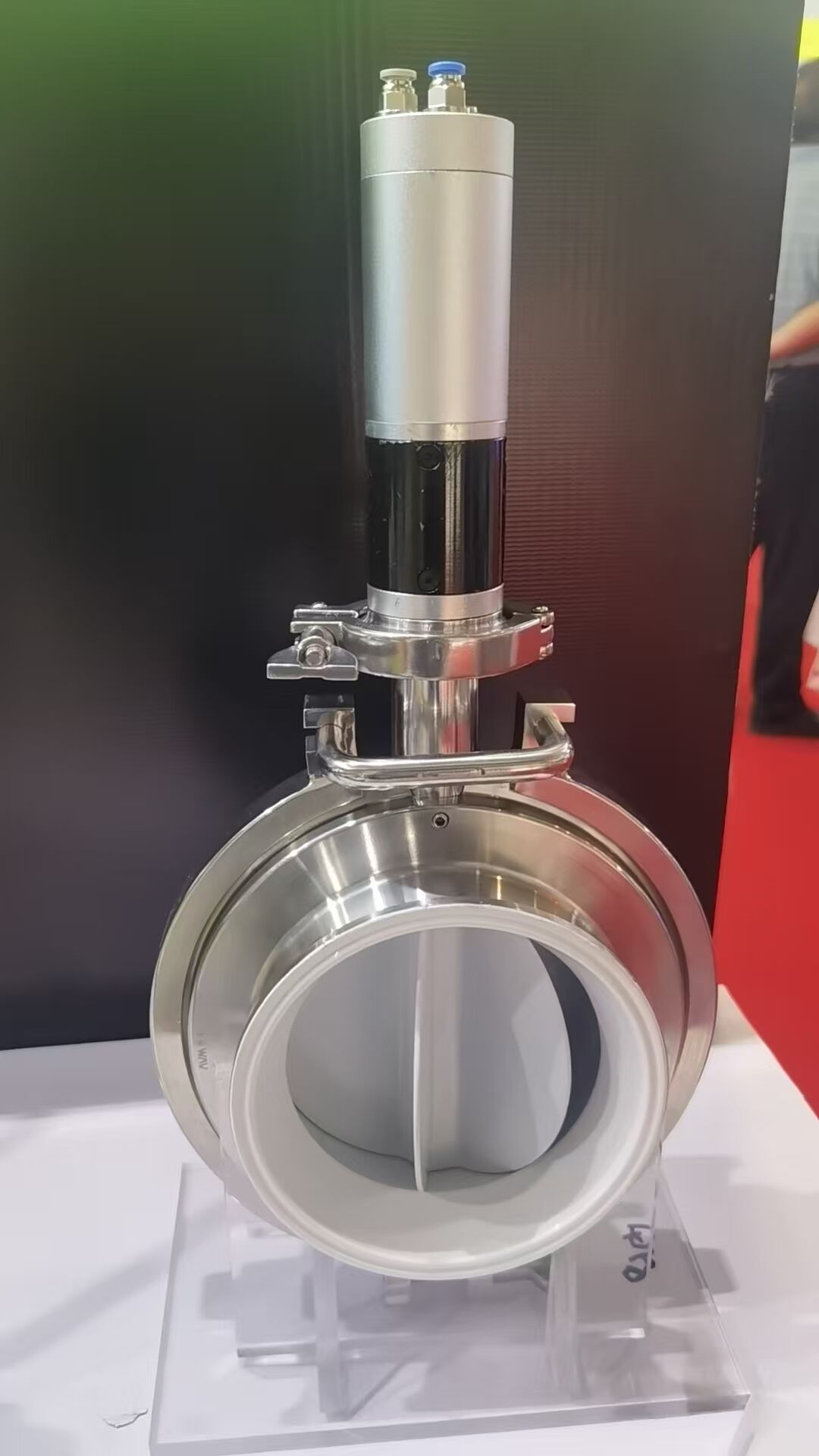

Ensuring Sealing Integrity for Fine, Hygroscopic, or Combustible Powders

Differential Pressure Testing, Leakage Rates, and ATEX-Compliant Rotary Valve Sealing Systems

Getting proper sealing right matters a lot when moving around fine powders, especially those that pick up moisture or can catch fire. Small particles find their way through tiny gaps between components. Moisture loving materials start absorbing humidity as soon as they're exposed to air. And then there's the whole issue with combustible dusts creating fire hazards whenever oxygen gets in or static electricity builds up. To check how good the seals really are, most facilities run differential pressure tests where they apply actual pressure differences across valves to see what kind of leaks might happen during normal operation. Most industries set a maximum leakage limit at 0.5% for anything considered dangerous. Systems built according to ATEX standards include things like continuous purge air flow, special seals that stop flames from spreading, and materials that conduct electricity away from potential sparks. These help keep everything contained and safe. Using hardened surfaces on seals plus adjustable end plates helps maintain that crucial tight fit even after repeated heating cycles or when dealing with gritty substances. This approach keeps operations compliant with regulations while maintaining product quality and overall plant safety.

Addressing Thermal, Moisture, and Electrostatic Challenges in Sensitive Powder Handling

Caking Prevention via Temperature Control and Static Dissipation in Rotary Valve Design

When temperatures fluctuate or moisture gets into the mix, it causes problems like caking and disrupted flow in processing lines. Special jacketed housing systems with temperature control help stop this condensation problem from happening by keeping things consistent inside. At the same time, static electricity builds up quite a bit in those dry polymer powders we work with, sometimes reaching over 5,000 volts. This static makes particles stick together and form bridges that block the flow. The solution? Using conductive materials for rotors such as carbon filled composites or metal vanes connected to ground points. These materials let the static charge escape properly, which cuts down on bridging issues by around two thirds for materials that absorb moisture easily. We also install sensors throughout the system to keep an eye on both humidity levels and electrical charge on surfaces. Based on what these sensors tell us, operators can adjust things like how much purge air is flowing or how fast the rotor spins. This combination approach works really well for moving pharmaceutical ingredients, printer toner, and all sorts of materials that are particularly sensitive to static electricity buildup.

FAQ Section

What is rotary valve design for powder flow behavior?

Rotary valve design involves optimizing angles, clearances, and pocket shapes to mitigate issues like bridging, cohesive buildup, and wear caused by the powder's flow properties.

Why is the angle of repose important?

The angle of repose helps predict bridging problems in rotary valves. Materials with an angle of repose above 50 degrees tend to get stuck, necessitating design adjustments.

How does Mohs hardness affect rotary valve wear?

Materials with a Mohs hardness of 5 or higher can cause significant abrasive wear on valve components, requiring wear-resistant solutions like hardened alloys and ceramic linings.

How can sealing integrity be ensured for fine powders?

Proper sealing can be achieved through differential pressure testing, using ATEX-compliant systems, and utilizing materials that prevent leakage and fire hazards.

What solutions address thermal and electrostatic challenges?

Temperature control systems and conductive rotor materials prevent issues such as caking and static buildup, ensuring uninterrupted flow of sensitive materials.