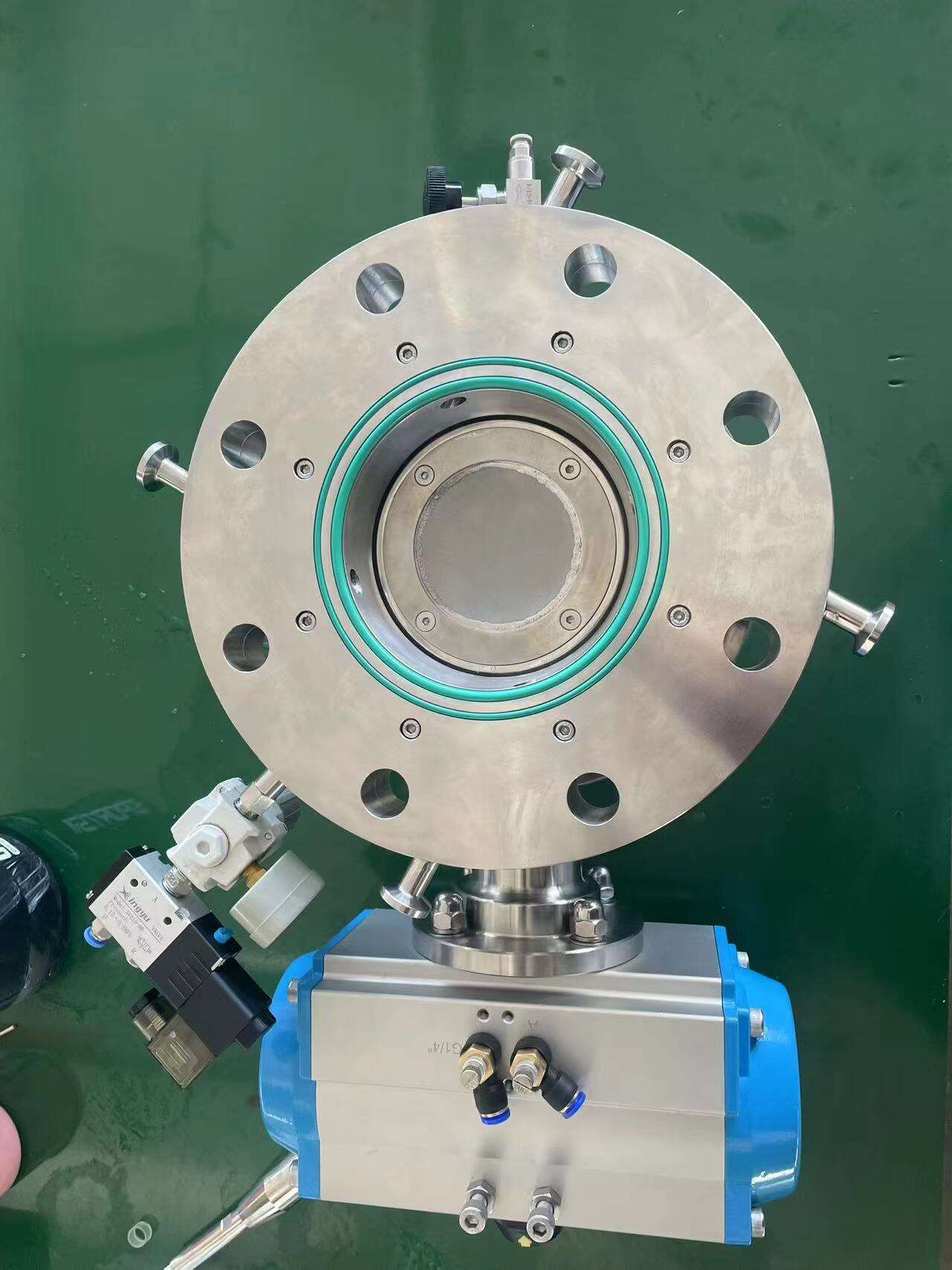

Reliable Inflatable Seals for Versatile and Effective Sealing Solutions

Inflatable Seals offer an innovative solution for sealing systems in dynamic and high-pressure environments. When inflated, these seals expand to form a tight, secure barrier, and when deflated, they can be easily removed or adjusted. They are ideal for sealing doors, valves, and other components in industries such as food, pharmaceutical, and chemical manufacturing, where maintaining clean and sterile conditions is critical. Inflatable Seals are effective for use in sterilization chambers, HVAC systems, and material transport systems, where their ability to seal around irregular shapes ensures minimal leakage and enhanced process control. These seals are highly flexible and can adapt to various applications, providing an efficient sealing solution that prevents contamination, reduces energy consumption, and minimizes maintenance.

Get A Quote