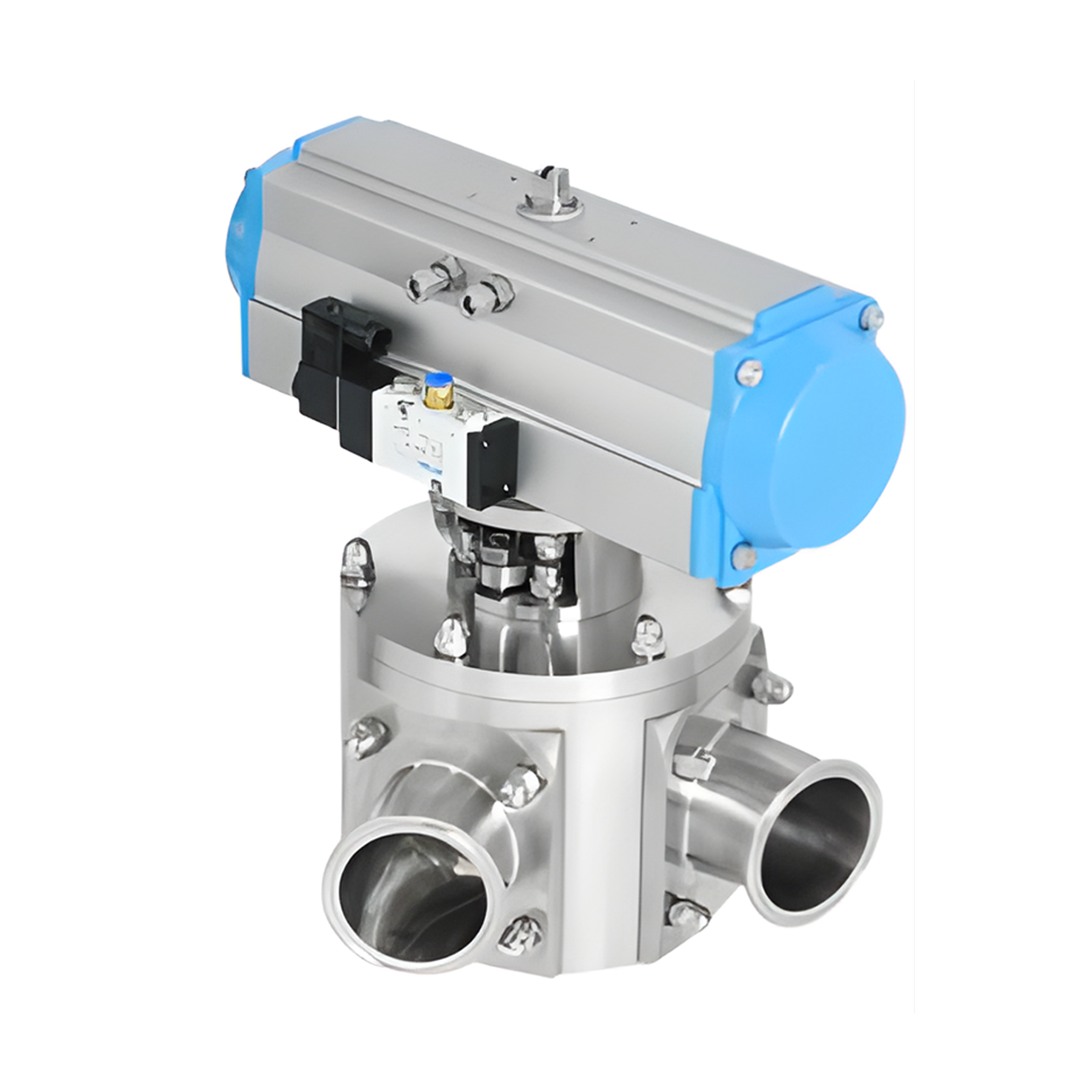

Advanced Powder Handling with Powder Valves

Designed specifically for powder material transfer, the Powder Valve uses dry gases (air, nitrogen, argon) to encase powder particles, reducing friction and preventing blockages in narrow openings. This innovative valve minimizes the need for lubricants and ensures smooth powder flow, ideal for a wide range of granular materials. The valve is robust, with no moving parts, offering superior control, and is available in various sizes to meet different needs, from small batch filling to large-scale production.