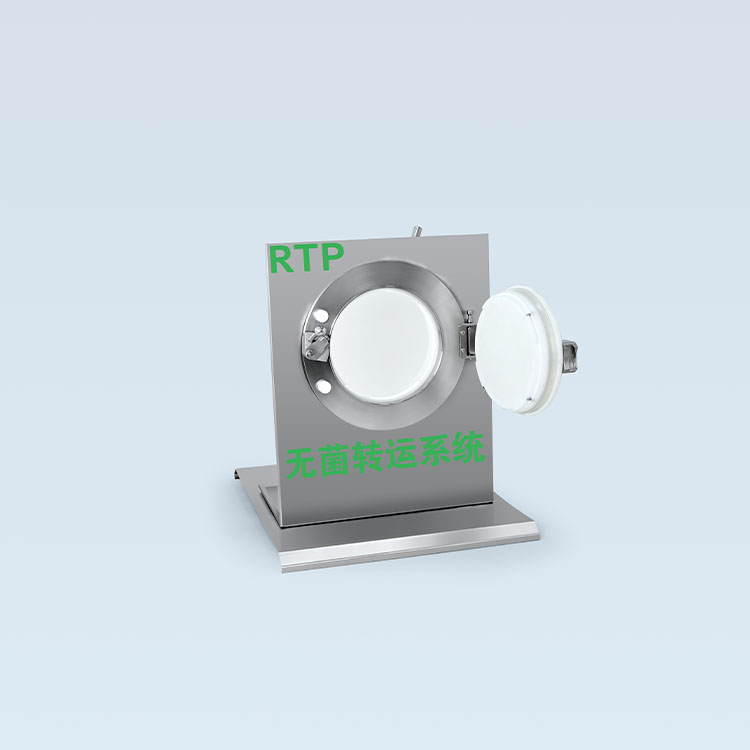

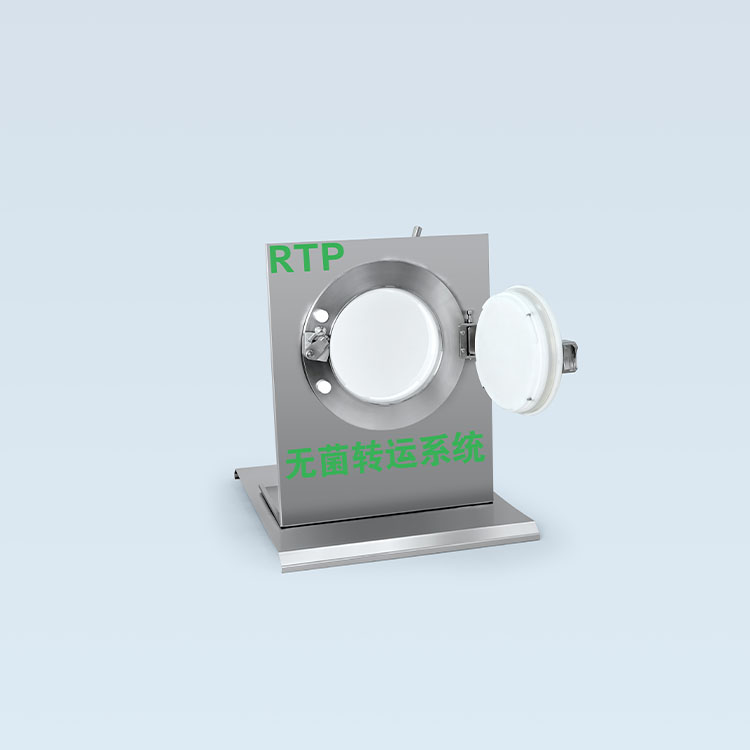

High-Security Rapid Transfer Ports for Sterile Material Handling

Rapid Transfer Ports (RTP) are an essential tool in maintaining sterile conditions during material transfers in environments such as pharmaceutical manufacturing, biotech labs, and cleanrooms. These ports feature a double-door system that ensures no contamination occurs during transfer between sterile zones. Their ergonomic design includes a low-effort handle mechanism that allows easy opening with minimal force, improving operator safety and efficiency. Designed for simple maintenance, the ports have smooth surfaces and no exposed fasteners, making them easy to clean and decontaminate. Ideal for environments requiring high sterility, RTPs protect the integrity of sensitive materials, ensuring compliance with strict industry standards for contamination control.

Get A Quote