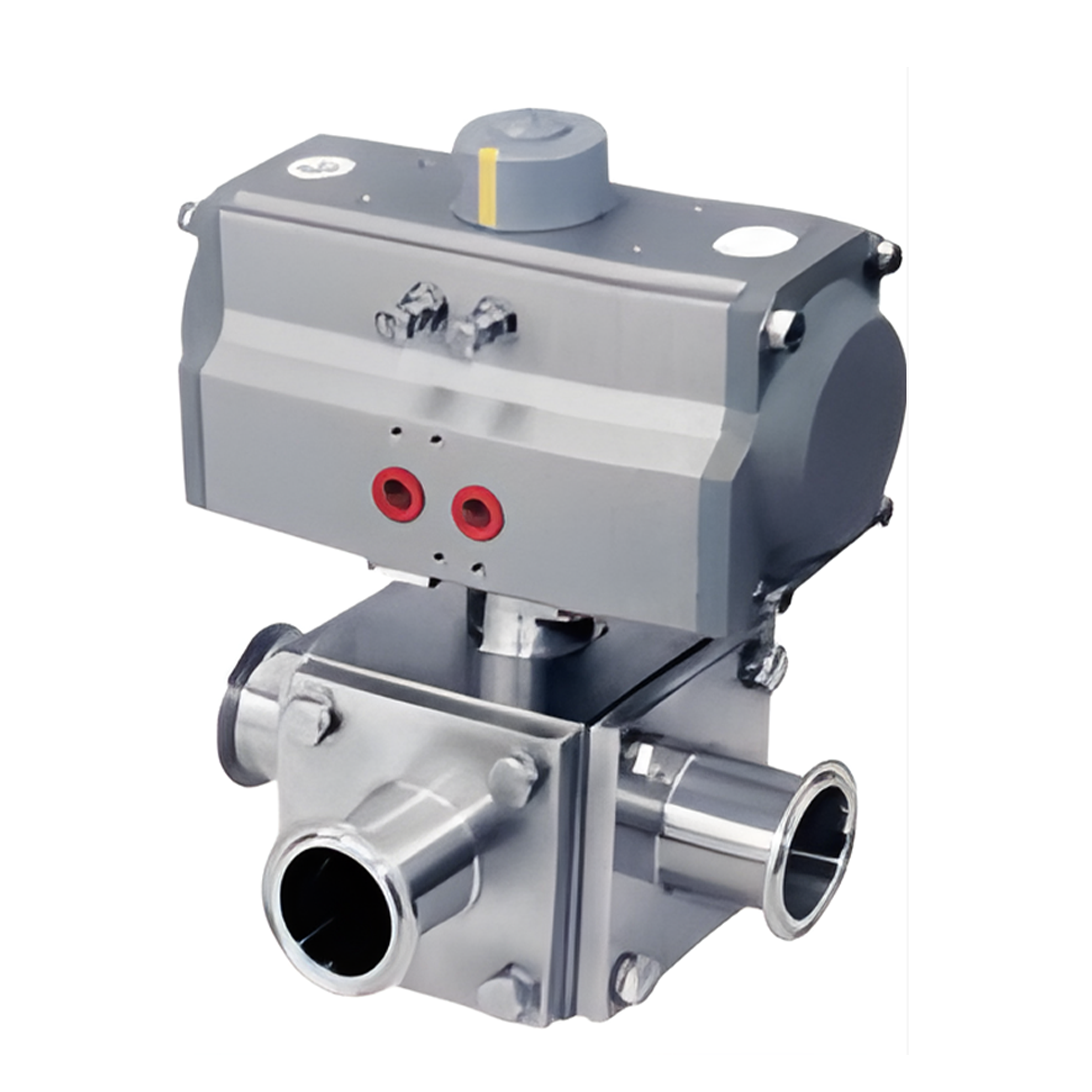

Precision Pneumatic Control Valves for Fluid and Gas Regulation in Industrial Applications

Pneumatic Control Valves are essential components for industries requiring precise control over fluid and gas flow. These valves use compressed air to actuate the valve, enabling accurate adjustments of flow rates, pressures, and other system parameters. Built from durable materials such as stainless steel, brass, and ductile iron, they are designed for use in harsh and corrosive environments, ensuring long-lasting reliability and performance. Pneumatic Control Valves are widely employed across various sectors, including chemical processing, automotive, and textiles, where they contribute to precise automation and efficiency. They offer benefits such as fast response time, low maintenance, and cost-effective performance in a wide range of operational conditions, from high pressures to hazardous environments.

Get A Quote