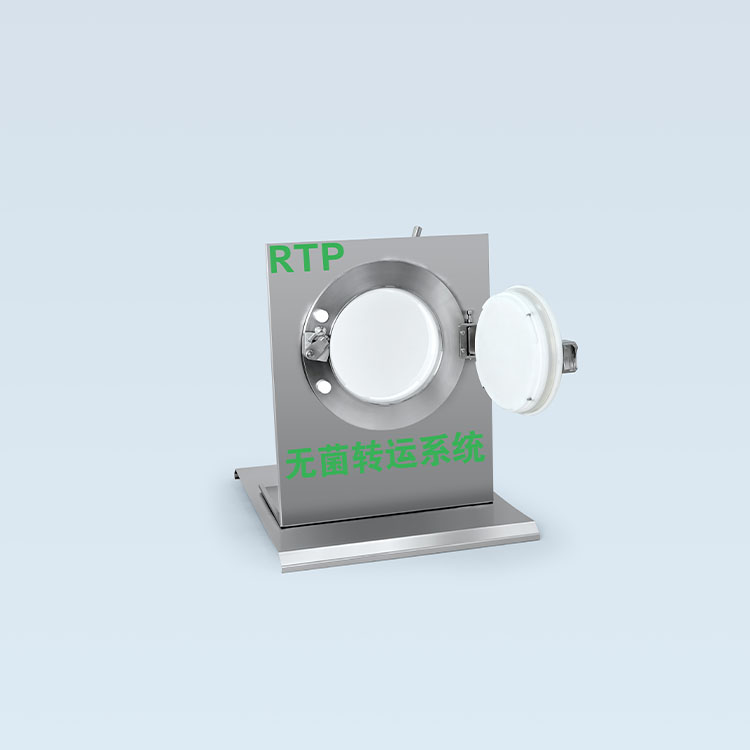

Seamless and Sterile Material Transfers with Rapid Transfer Ports

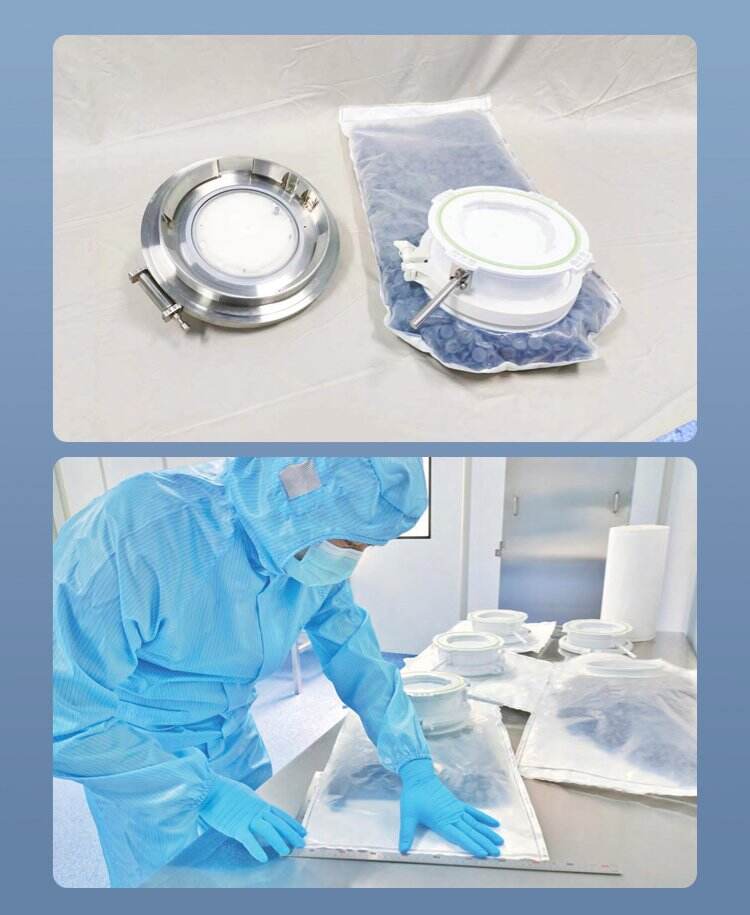

Rapid Transfer Ports (RTP) are designed for high-efficiency and safe material transfers in environments where sterility is essential, such as in pharmaceutical and biotech industries. These ports are equipped with a double-door system that ensures no contamination occurs when transferring materials between sterile zones. The innovative handle design minimizes the force needed to break the seal on beta containers, reducing operator effort and increasing safety. Additionally, the ports come with a streamlined interlocking mechanism and smooth, easy-to-clean surfaces, making them ideal for maintaining sterility in controlled environments. The design makes RTPs an invaluable asset in situations involving hazardous or sensitive materials, ensuring a secure and contamination-free transfer process.

Get A Quote