High-Efficiency Inflatable Seals for Secure and Flexible Sealing Solutions

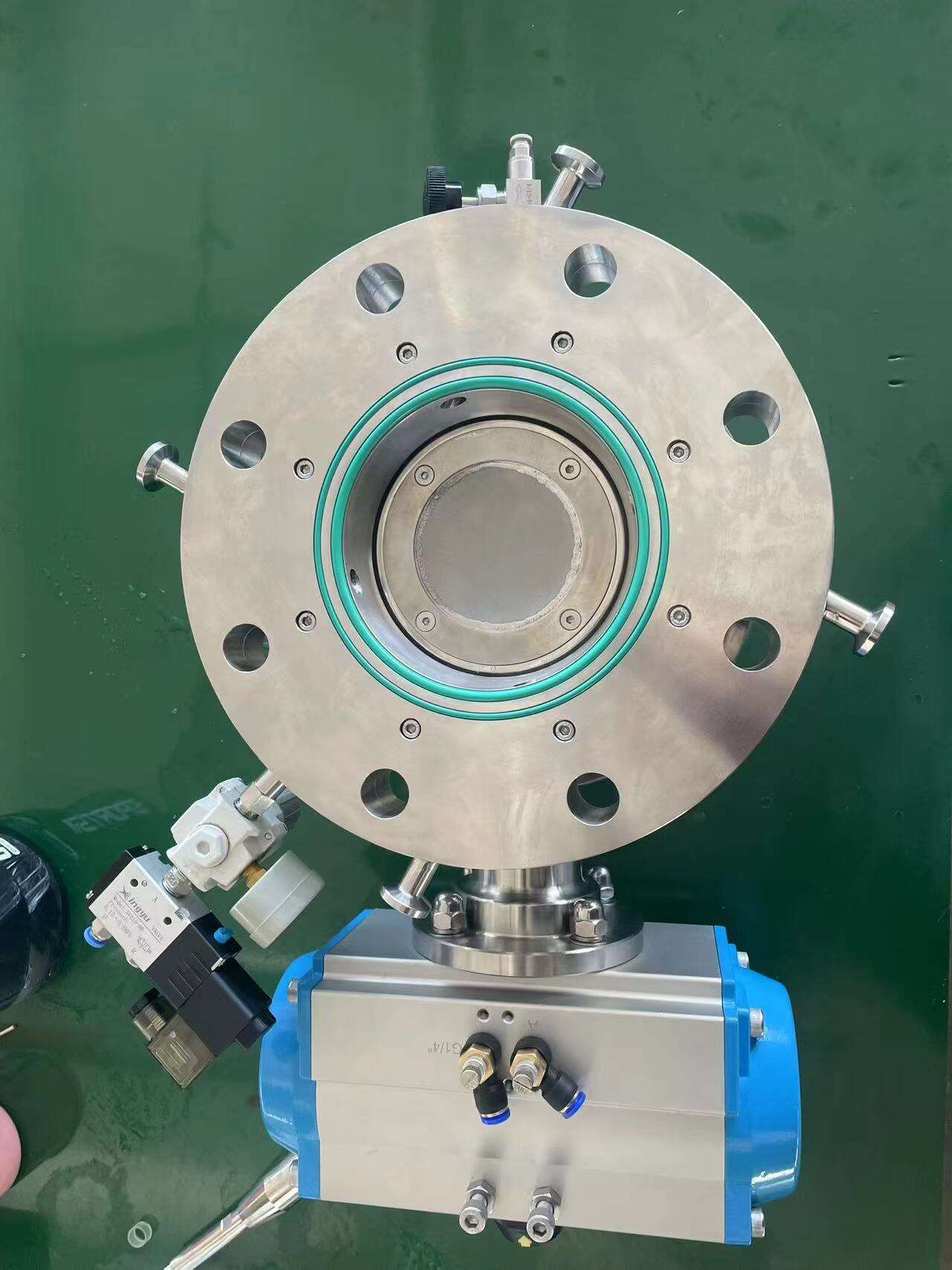

Inflatable Seals are an innovative solution for ensuring effective sealing in dynamic and challenging environments. When inflated, these seals expand to form a tight seal, and they contract when deflated for easy installation and removal. Made from a highly flexible and durable material, they are capable of adapting to different shapes and sizes, making them versatile across a variety of industries. Commonly used in sectors like food processing, pharmaceuticals, textiles, and transportation, Inflatable Seals are ideal for sealing doors, valves, and containers. Their ability to create a reliable, flexible barrier makes them a critical component for preventing contamination and ensuring operational integrity. In industries such as packaging, sterilization, and high-pressure environments, Inflatable Seals offer a cost-effective and efficient sealing solution while minimizing downtime during maintenance.

Get A Quote