Understanding Rapid Transfer Ports and Their Role in Containment

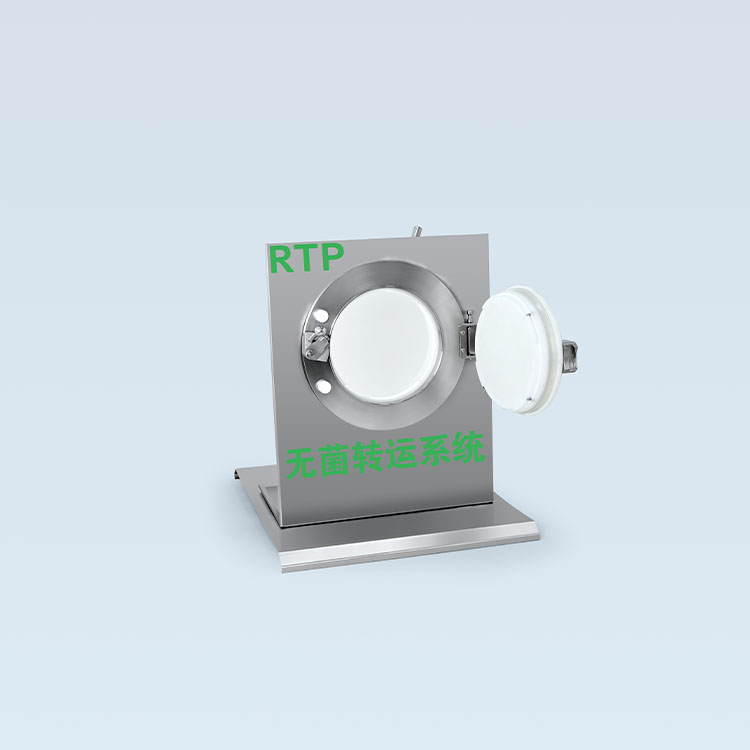

What Is a Rapid Transfer Port (RTP)?

A Rapid Transfer Port (RTP) is a closed-system technology that enables sterile material transfer between two isolated environments while maintaining containment. Originally developed in the 1960s for nuclear applications, modern RTP systems combine dual-door mechanisms and mechanical interlocks to prevent cross-contamination during pharmaceutical, biotech, or chemical manufacturing processes.

Double-Door Design for Contamination Prevention

RTPs use a fail-safe double-door design where the alpha (fixed) and beta (mobile) doors cannot open simultaneously. This prevents airborne particles or microbial contaminants from entering either environment during transfers. Facilities using this design reduced particulate ingress by 89% compared to manual transfer methods, according to a 2023 industry survey.

Mechanical Interlock Systems to Ensure Safe Material Transfer

Integrated mechanical interlocks enforce sequential door operation:

- The alpha door remains locked until the beta container securely attaches

- A physical barrier engages if improper alignment occurs

- Audible alerts trigger if seal integrity falters

This minimizes human error during transfers of cytotoxic compounds or sterile ingredients, aligning with FDA containment guidelines for high-risk materials.

Key Applications in Handling Hazardous and Potent Compounds

RTP systems are critical for transferring:

- Chemotherapy agents requiring OEB 4/5 containment

- Gene therapy vectors with viral inactivation protocols

- Sterile APIs in isolator-based filling lines

Over 75% of FDA-approved biologics facilities now deploy RTPs to meet Annex 1 requirements for closed-system processing, underscoring their importance in modern contamination control strategies.

Aseptic Manufacturing and Sterility Assurance with RTP Technology

Integrating RTPs into Aseptic Processing Workflows

Modern pharmaceutical facilities use rapid transfer ports (RTPs) to automate material transfers while maintaining ISO 5 cleanroom standards. These systems interface seamlessly with isolators, restricted access barrier systems (RABS), and single-use assemblies, reducing human intervention by 84% in critical workflows (Pharmaceutical Technology, 2023).

Maintaining Sterility During Material Transfer

RTPs prevent microbial ingress through mechanical interlocks and double-door seals. A 2023 validation study across 17 facilities demonstrated a 98% reduction in contamination incidents when transferring temperature-sensitive biologics using RTP technology.

Validation Protocols: Seal Integrity, Particle Control, and Sterility Testing

Three critical validation criteria ensure RTP reliability:

| Parameter | Test Method | Acceptance Standard |

|---|---|---|

| Seal Integrity | Pressure decay tests | ≤0.5% leak rate over 30 min |

| Particle Control | Laser particle counters | ≤3,520 particles/m³ (≤0.5μm) |

| Sterility Assurance | Biological indicators (Geobacillus stearothermophilus) | 6-log reduction |

RTP Use in Isolators and Cleanrooms for Product Purity

In Grade A environments, RTPs enable transfers of gamma-irradiated materials with 99.99% sterility assurance. Their compatibility with isolator systems has driven a 32% annual increase in closed-processing adoption for high-potency APIs (Grand View Research, 2023).

Design Components and Functional Mechanisms of RTP Systems

Rapid Transfer Port (RTP) systems ensure safe material transfer through precision-engineered components that maintain sterility while enabling efficient pharmaceutical workflows. Their functional design directly addresses contamination risks in critical manufacturing processes.

Alpha and Beta Flange Connections in Sterile Docking

At the heart of RTP tech we find this special pairing of alpha and beta flanges. When these parts lock together they form what engineers call a closed system path. Materials can move safely from one isolation chamber to another container without letting anything from outside get in. The alpha side stays put on whatever machinery it's connected to. Meanwhile the beta part connects to those transfer vessels. There's this clever rotating collar thingy that makes sure everything lines up just right for an airtight seal before the actual connection happens. Pretty neat engineering solution really.

Beta Assemblies: Canisters, Autoclavable Containers, and Liquid Ports

Beta-side configurations adapt to diverse transfer needs. Stainless steel canisters handle high-temperature sterilization for solid materials, while disposable polymer containers suit single-use biologics. Specialty liquid ports integrate pressure-equalization filters for fluid transfers, maintaining sterility across viscosity ranges from cell cultures to viscous ointments.

Design Features for Safety, Durability, and Ease of Use

Modern RTP systems incorporate fail-safe interlock sensors that prevent door opening until proper sealing completes. Ergonomic clamp designs reduce operator fatigue during repeated transfers, and corrosion-resistant coatings withstand harsh disinfectants like hydrogen peroxide vapor. Standardized color-coding (blue for alpha, orange for beta) simplifies identification in fast-paced cleanroom environments.

Material Compatibility and System Scalability in Pharmaceutical Settings

Grade 316L stainless steel dominates contact surfaces for corrosion resistance, while ethylene propylene diene monomer (EPDM) gaskets ensure compatibility with sterilization methods. Modular flange sizes (8³ to 16³ diameters) enable scaling from clinical trial batches to commercial production, with validation protocols ensuring consistent performance across operational scales.

Regulatory Compliance and Validation Requirements for RTP Systems

Meeting FDA, EU Annex 1, and cGMP Standards in RTP Design

For RTP systems used in pharma manufacturing, compliance with various regulations is absolutely essential when it comes to safely moving materials around. Let's start with the basics: under 21 CFR Part 11 from the FDA, all those electronic records need to stay intact and tamper proof. Then there's EU Annex 1 which gets specific about keeping ISO 5 cleanroom conditions during transfers. And don't even get me started on cGMP requirements. Manufacturers have to thoroughly test those mechanical interlocks and check every gasket seal for leaks because we're talking about preventing cross contamination between batches. One tiny failure here could mean contaminated products reaching patients, so this isn't just paperwork it's actual patient safety at stake.

| Standard | Key Requirement | Validation Focus |

|---|---|---|

| FDA 21 CFR Part 11 | Audit trails for electronic records | Data integrity |

| EU Annex 1 | ≤ 3,520 particles/m³ (≤ 0.5 ¼m) | Airflow uniformity |

| cGMP | ≤ 1x10⁻⁶ mbar·L/s leak rate | Seal integrity testing |

Industry Best Practices for Double-Door Containment Systems

Leading facilities implement pressure decay testing every 6 months to validate double-door integrity. Mechanical interlocks prevent simultaneous door openings, reducing cross-contamination risks by 99.97% in OEB 5/6 environments. Airflow studies using smoke visualization ensure unidirectional flow during transfers, maintaining ISO 14644-1 Class 5 conditions.

Documentation and Qualification Processes for Audit Readiness

A 2023 survey revealed 78% of FDA citations involved incomplete RTP lifecycle documentation. Robust protocols include:

- Installation Qualification (IQ) records of flange alignment tolerances

- Operational Qualification (OQ) data for transfer cycle times

- Performance Qualification (PQ) evidence of sterile boundary maintenance

Electronic logbooks with 21 CFR Part 11-compliant signatures streamline audit processes, reducing review times by 40% compared to paper systems.

Applications of Rapid Transfer Ports in Biopharmaceutical Production

RTPs in Aseptic Filling Lines and Closed-System Transfer

Rapid Transfer Ports (RTPs) enable secure material transfers in high-risk biopharmaceutical workflows like aseptic filling, where sterility is non-negotiable. Their double-door mechanism prevents airborne contaminants during vial or syringe filling, while closed-system transfers maintain product integrity for sensitive biologics like monoclonal antibodies.

Use of RTP Technology in Bioprocessing and Cell/Gene Therapy

In cell/gene therapy workflows, RTPs ensure compatibility with single-use bioreactors and isolators, reducing cross-contamination risks during media transfers or harvest steps. Their beta flange design allows seamless docking with cryogenic containers, critical for preserving cell viability during cryopreservation.

Expanding RTP Utility Across Life Science Research and Manufacturing

These days, folks working in pharmaceutical innovation are turning to RTP technology across various applications including vaccine manufacturing, managing sterile APIs, and containing those dangerous cytotoxic substances. Some recent research found that facilities using RTP systems saw nearly half the contamination problems compared to older methods – specifically a drop of around 47%. The beauty of these systems lies in their scalability too. They work just as well in small labs running test batches as they do in full scale production environments. This flexibility makes them particularly attractive given how regulations keep changing toward requiring more closed processing systems throughout the industry.

Frequently Asked Questions

What materials can be transferred using RTP systems?

RTP systems can transfer a wide range of materials including chemotherapy agents, gene therapy vectors, sterile APIs, and temperature-sensitive biologics. They are adaptable to various conditions and requirements based on their design configurations.

What makes RTP systems compliant with regulatory standards?

RTP systems comply with standards such as FDA 21 CFR Part 11, EU Annex 1, and cGMP by maintaining sterile conditions during transfers, ensuring data integrity in electronic records, and utilizing proper testing for mechanical and seal integrity.

How do RTP systems prevent cross-contamination?

RTP systems use a double-door mechanism with mechanical interlocks to prevent simultaneous door openings which reduces cross-contamination risks by maintaining containment between environments.

What are the benefits of using RTPs in aseptic manufacturing?

The use of RTPs in aseptic manufacturing ensures sterility and compliance with cleanroom standards, reduces human intervention, and decreases contamination incidents significantly.

Table of Contents

- Understanding Rapid Transfer Ports and Their Role in Containment

- Aseptic Manufacturing and Sterility Assurance with RTP Technology

- Design Components and Functional Mechanisms of RTP Systems

- Regulatory Compliance and Validation Requirements for RTP Systems

- Applications of Rapid Transfer Ports in Biopharmaceutical Production

- Frequently Asked Questions