Superior Sealing Integrity in Dynamic and Critical Applications

Inflatable seals beat traditional compression methods because they create basically airtight closures using controlled air or fluid pressure. Traditional seals just sit there with their fixed compression force, while these newer ones actually adjust how pressure gets distributed across uneven surfaces. That matters a lot for vacuum systems since even tiny leaks around 0.01 pascals can mess things up completely. A recent article in the Materials Engineering Journal looked at this stuff back in 2023 and found that inflatable seals kept about 99.8 percent integrity when switching between pressures from almost nothing (like 0.00001 millibar) all the way up to regular atmospheric pressure levels. Metal gaskets only managed around 82% under similar conditions. Semiconductor manufacturers really need this kind of flexibility too. One factory actually saw particle contamination drop by roughly three quarters after swapping over to these inflatable systems, which makes sense given how sensitive cleanrooms are to microscopic contaminants.

Exceptional Adaptability to Irregular and Complex Surfaces

Challenges of Sealing Non-Uniform Geometries with Traditional Methods

Standard fixed shape seals and gaskets have real trouble dealing with surfaces that aren't perfectly smooth, which leaves tiny gaps where they just don't perform right. According to research published last year in Manufacturing Technology Journal, about 38 percent of those rubber based seal failures happened when the surface was off by more than half a millimeter in flatness. The old school compression techniques actually make things worse because they create all sorts of pressure inconsistencies across the contact area. This becomes a big problem on those bent metal flanges or rough surfaces we see so often in chemical processing plants throughout the industry.

Conformability Principle: How Inflatable Seals Adjust to Surface Variations

Inflatable seals use pneumatic or hydraulic pressure to conform precisely to substrate imperfections, ensuring uniform sealing force across challenging interfaces. They effectively accommodate:

- Surface roughness up to 25 µm

- Geometric tolerances exceeding ±2 mm

- Dynamic alignment shifts during thermal cycling

Advancements in polymer materials now enable 360° radial expansion ratios of up to 12:1 while maintaining tensile strength above 15 MPa, as verified under ISO 9147-compliant testing protocols.

Case Study: Pharmaceutical Processing Equipment Integration

An upgrade to a tablet coating system highlighted the advantages of inflatable seals:

| Parameter | Traditional O-Ring | Inflatable Seal | Improvement |

|---|---|---|---|

| Surface Tolerance | ±0.3 mm | ±1.8 mm | 6x |

| Seal Replacement Frequency | Quarterly | Biannually | 50% |

| Sterilization Cycle Resistance | 150 cycles | 500+ cycles | 3.3x |

The switch reduced equipment downtime by 60% and met FDA-grade aseptic standards, demonstrating both operational and compliance benefits.

Growing Use in Custom Industrial Fabrication

The global market for adaptive sealing solutions in custom machinery grew 17% year-over-year in 2023, according to the Industrial Automation Report. Manufacturers increasingly specify inflatable seals for:

- Additive-manufactured components with layer-line surface textures

- Multi-material assemblies requiring compensation for differential thermal expansion

- Robotic end-effector tooling with reconfigurable interfaces

This shift supports Industry 4.0 goals, enabling flexible, high-mix, small-batch production systems with self-adjusting capabilities.

Energy Efficiency and Low Actuation Force Requirements

Drawbacks of High Clamping Forces in Mechanical Seals

Mechanical seals usually need around 30 to 50 percent more clamping force compared to inflatable options before they can match performance levels according to data from last year's Energy Efficiency report for industrial systems. The extra pressure really takes a toll on those contact points between parts and means building stronger support structures too. Because of this problem, many engineers end up going bigger with their motor sizes and hydraulic equipment. This creates what some call an energy waste cycle, where nearly half (about 42%) of all electricity consumed ends up being used just to overcome friction caused by these sealing mechanisms, something highlighted in a recent analysis of fluid power systems back in 2022.

Pneumatic and Hydraulic Expansion: Reducing System Load

Inflatable seals convert stored pneumatic or hydraulic energy into uniform radial pressure via controlled membrane expansion. This mechanism reduces actuation energy needs by 60–80% compared to compression-based methods. A 2021 study of rotary feedthrough systems showed inflatable seals achieve effective sealing at just 7–12 psi, versus 35–50 psi required by conventional designs.

Case Study: Lightweight Closure Systems in Cleanroom Doors

One pharmaceutical company managed to cut down on cleanroom door actuation energy consumption by a whopping 74% simply by switching out old equipment for inflatable seals. Before this upgrade, they had been using those traditional spring loaded systems that needed massive 450 watt motors just to keep things at ISO Class 5 standards. The new setup works wonders too, keeping particles out much better while running on modest 120 watt servo pneumatic controls instead. What's even better? Maintenance doesn't need to happen every three months anymore but can wait until once every two years now. Looking ahead, these changes should save them over $280k in energy costs alone within five years according to recent findings published in the Pharma Engineering Journal back in 2023.

Trend: Compatibility With Low-Power Automation Systems

Today's inflatable seals work pretty well with Industry 4.0 systems thanks to built-in pressure sensors and those smart valves connected to the internet. The ability to monitor and adjust these seals in real time has made a big difference. According to the Smart Manufacturing Market Review from 2024, factories using this tech typically save between 18 and 22 percent on their energy bills across automated production lines. No wonder why so many plant managers are turning to inflatable seals for their solar powered operations and battery driven machinery. When every watt counts, these seals just make sense for cutting down on power needs without sacrificing performance.

Extended Durability and Reduced Maintenance Downtime

Premature Wear in Traditional Elastomeric and Mechanical Seals

Traditional compression seals often degrade within 6–12 months in high-cycle environments due to abrasive wear and plastic deformation. A 2023 tribology study revealed that elastomeric seals lose 40% of their sealing force after just 50,000 compression cycles, increasing leakage risks in pumps and valves.

Reduced Friction and Contact Stress in Inflatable Seal Design

By engaging only when inflated, these seals reduce surface contact by 60–80% compared to static counterparts. This on-demand operation lowers wear rates by 3.5x in reciprocating applications, according to ISO 3601-3 test data.

Data Insight: 3x Longer Lifespan in Reciprocating Valve Applications

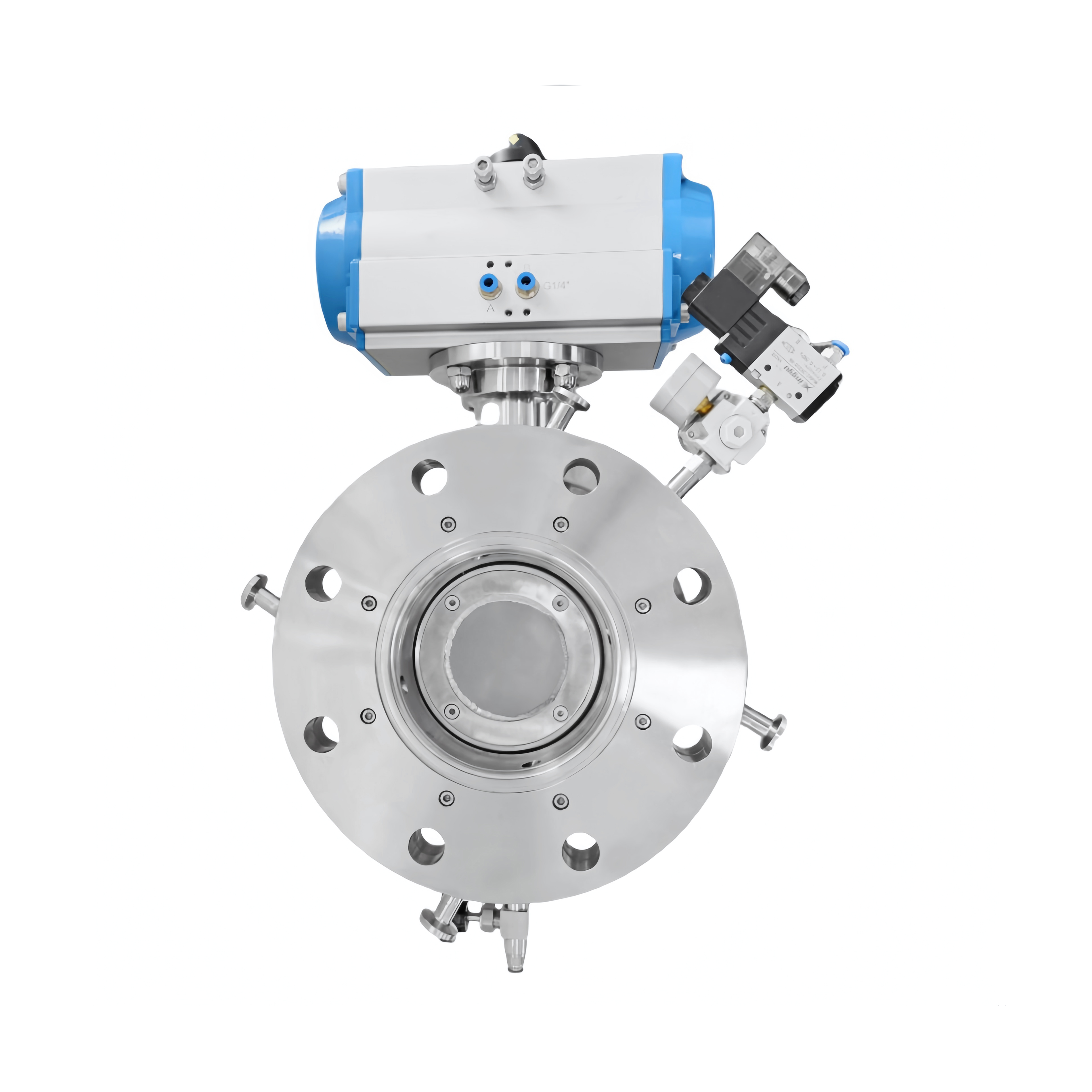

Field data from petrochemical plants show inflatable seals averaging 18,000 hours of service life in quarter-turn valves—three times longer than PTFE-encapsulated mechanical seals. This improvement correlates with a 34% reduction in annual maintenance costs, as reported by the Fluid Sealing Association in 2024.

Modular Construction for Quick Replacement and Reusability

- Cartridge-style designs allow seal replacement in under 15 minutes, compared to over two hours for bonded versions

- Maintenance logs approved by the USDA indicate 86% of users reuse inflation cores across three or more seal bodies

Case Study: Rapid Maintenance in Food and Beverage Processing Lines

A frozen food producer cut CIP system downtime by 72% after switching to inflatable door seals. The modular design enabled hygienic replacements during standard 15-minute sanitation breaks, eliminating the need for lengthy 4-hour maintenance windows.

Long-Term Cost-Effectiveness and ROI of Inflatable Seals

Hidden Costs of Frequent Traditional Seal Replacement

Conventional compression seals might cost less upfront, but they tend to fail often which creates all sorts of hidden costs down the road. Plants across the manufacturing sector are losing around $740k each year because of unexpected shutdowns caused by failed seals. The numbers tell us something interesting too - most of this money goes toward lost labor time and production delays, making up nearly 7 out of 10 dollars spent on these issues (Ponemon Institute reported similar findings back in 2023). When dealing with tough conditions where temperatures fluctuate wildly or chemicals are present, standard rubber seals just don't last long enough. Many facilities find themselves replacing them anywhere between half a year and a full year later depending on how brutal the environment gets.

Reusable Design and Lower Lifetime Material Costs

Inflatable seals reduce recurring procurement through modular, reusable construction. Unlike disposable gaskets, they remain functional beyond 500 inflation cycles, as confirmed by the 2024 Material Durability Report, cutting annual material needs by 70% in valve applications. Their urethane-reinforced membranes also resist abrasive particulates three times better than standard rubber seals.

Total Cost of Ownership Comparison with Traditional Seals

A five-year lifecycle analysis shows inflatable seals deliver a 40% lower total cost of ownership (TCO) despite higher initial investment. Key savings come from:

- Energy Efficiency: 22% reduction in pneumatic energy use due to optimized actuation pressures

- Maintenance: 15 fewer labor hours per seal annually thanks to simplified installation

- Downtime Avoidance: 98% operational uptime recorded in pharmaceutical freeze-dryers in a 2025 case study

Leading manufacturers report achieving return on investment within nine months, with net savings of $27,500 per seal over five years, according to the Industrial Research Group 2025.

Adoption in Sustainability-Focused Manufacturing Operations

Inflatable seals have become much more popular lately, with adoption rates jumping 31% since 2022 according to industry reports. The fact that these seals can be reused multiple times makes them great for companies trying to cut down on waste. Automotive battery manufacturers are seeing real results too, with some plants reporting an 18% drop in seal-related waste after switching to this technology. What's even better is how long they last. A recent EPA study from 2023 found that these seals reduce carbon emissions by around 26 tons of CO2 equivalent per production line each year. For businesses focused on meeting environmental standards, this kind of performance makes inflatable seals not just environmentally friendly but also smart business decisions in the long run.

FAQ

What are inflatable seals?

Inflatable seals are sealing solutions that use pneumatic or hydraulic pressure to form a tight seal around surfaces. They are known for their adaptability and effectiveness in dynamic and irregular applications.

How do inflatable seals compare to traditional seals?

Inflatable seals offer superior sealing integrity with adjustable pressure distribution, better conformability to uneven surfaces, increased energy efficiency, longer lifespan, and reduced maintenance compared to traditional compression seals.

Why should I consider using inflatable seals?

Inflatable seals are beneficial for applications requiring airtight closures, adaptability to complex geometries, energy efficiency, extended durability, and long-term cost-effectiveness. They are suitable for industries like semiconductor manufacturing, pharmaceutical processing, and sustainable manufacturing operations.

Are inflatable seals environmentally friendly?

Yes, inflatable seals can be reused multiple times, reducing waste and material needs. They also reduce carbon emissions, making them an environmentally friendly choice for green manufacturing operations.

Table of Contents

- Superior Sealing Integrity in Dynamic and Critical Applications

- Exceptional Adaptability to Irregular and Complex Surfaces

- Energy Efficiency and Low Actuation Force Requirements

-

Extended Durability and Reduced Maintenance Downtime

- Premature Wear in Traditional Elastomeric and Mechanical Seals

- Reduced Friction and Contact Stress in Inflatable Seal Design

- Data Insight: 3x Longer Lifespan in Reciprocating Valve Applications

- Modular Construction for Quick Replacement and Reusability

- Case Study: Rapid Maintenance in Food and Beverage Processing Lines

- Long-Term Cost-Effectiveness and ROI of Inflatable Seals

- FAQ