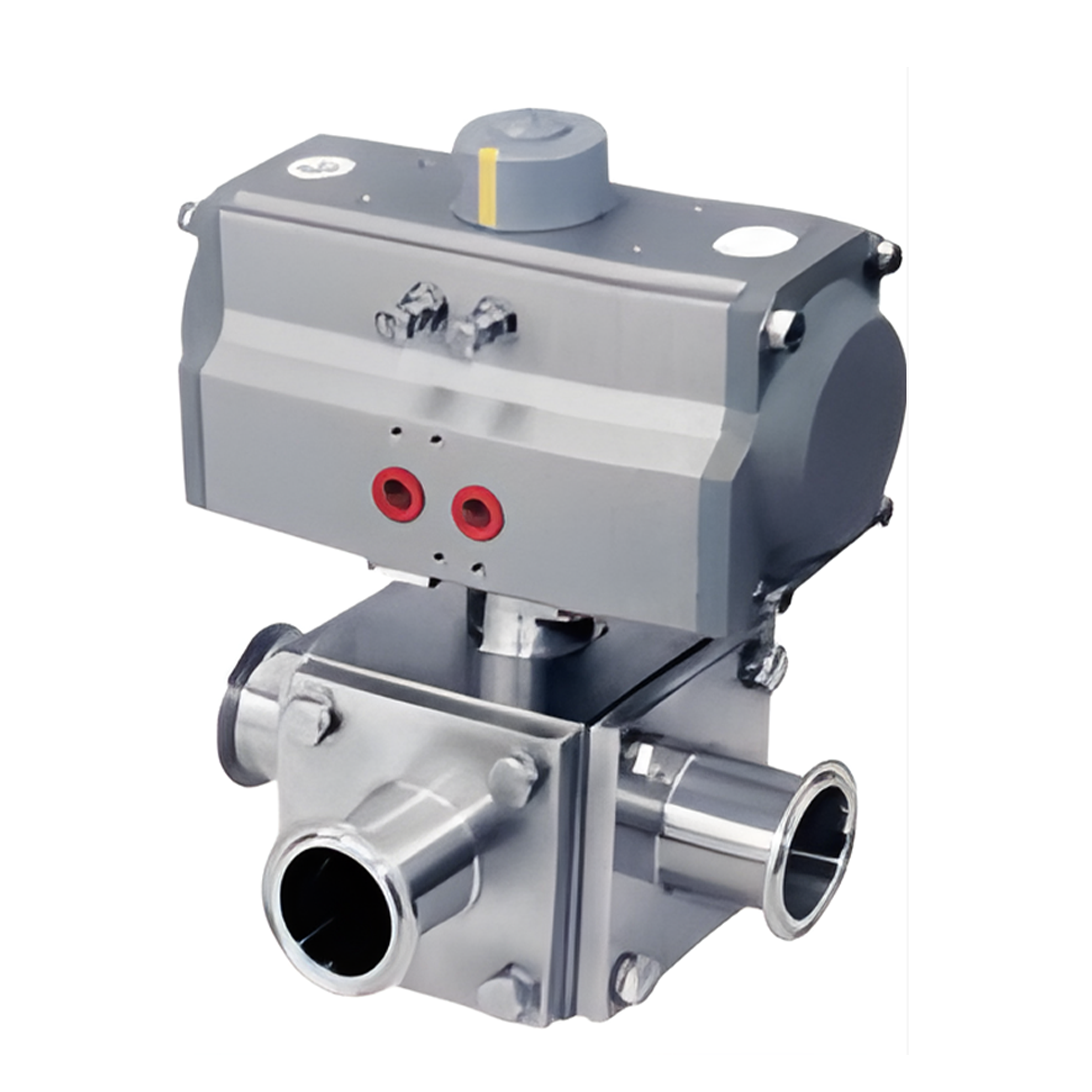

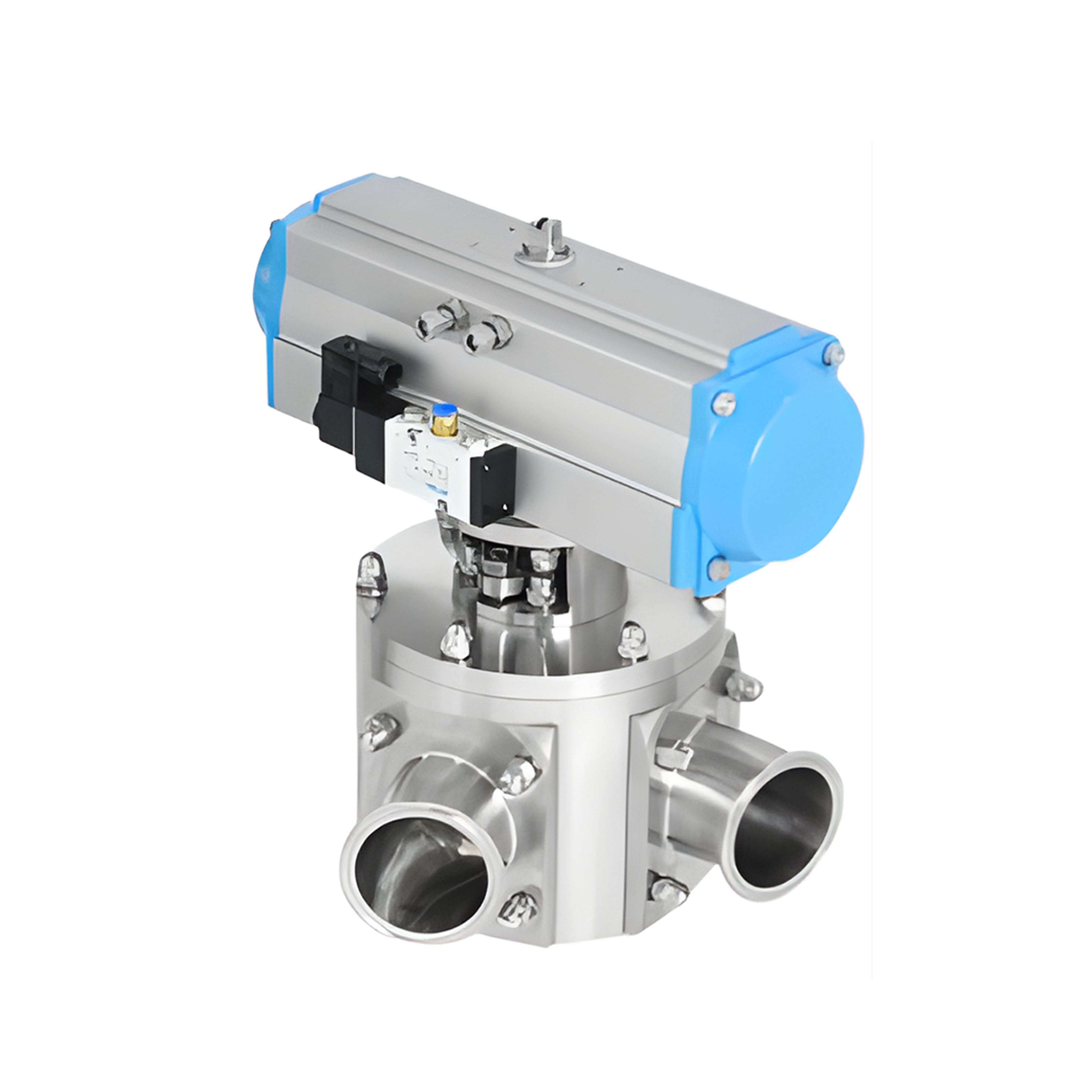

Efficient Divert Valves for Accurate Material Flow Direction and Distribution

Divert Valves are designed to control and redirect the flow of materials in systems where multiple pathways are needed. These valves are particularly effective in industries like powder processing, fluid distribution, and material handling, where it is necessary to direct flow to multiple destinations. By automating the flow distribution process, Divert Valves improve the efficiency and accuracy of material handling systems, ensuring that materials are delivered to the correct location without manual intervention. Whether used in material conveying systems, water treatment facilities, or production lines, these valves help reduce labor costs, minimize errors, and increase the speed of operations.

Get A Quote