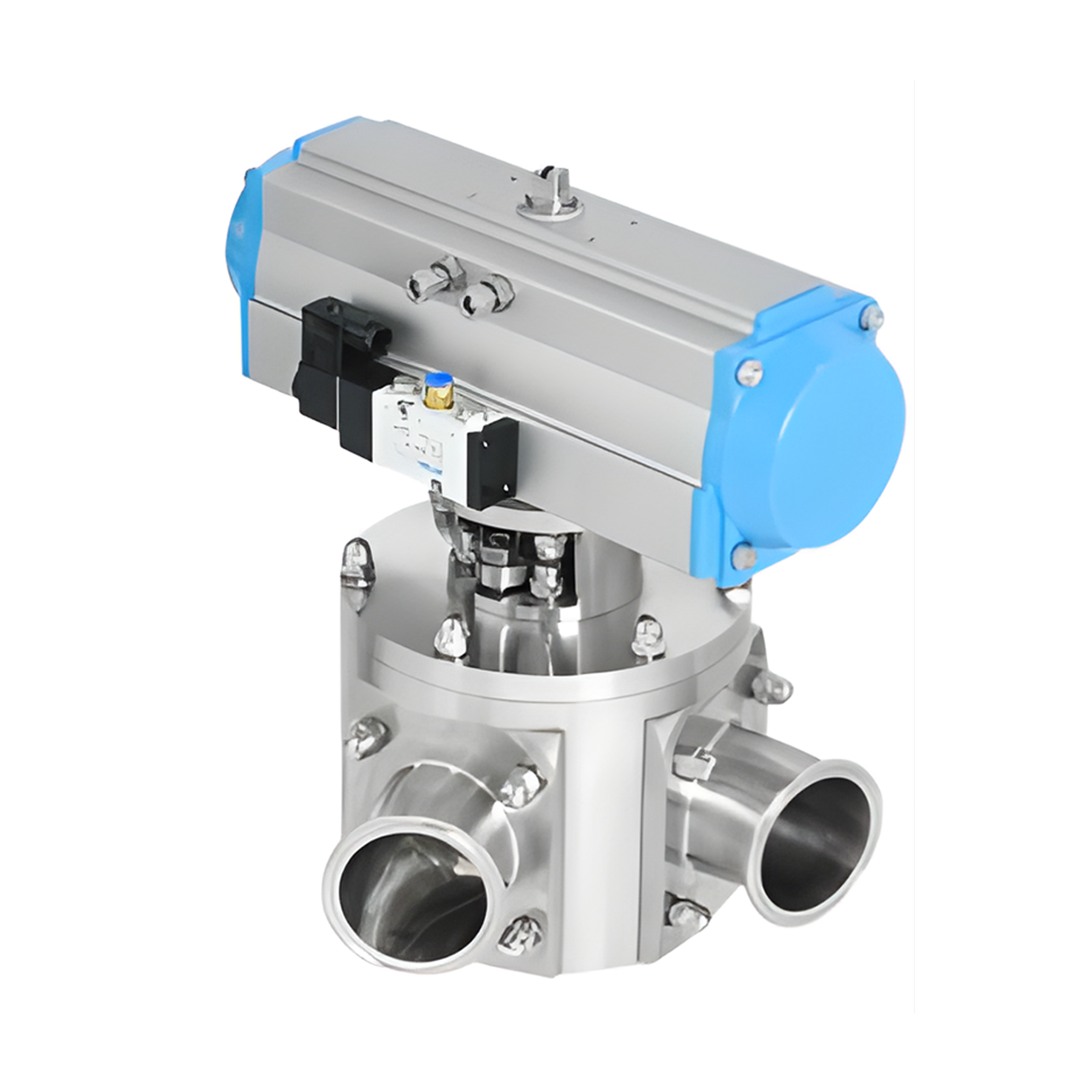

High-Performance Hygienic Valves for Critical Sanitation in Food and Pharma Industries

Hygienic Valves are engineered to meet the highest standards for sanitation in industries like food processing, pharmaceuticals, and bioprocessing. These valves ensure that materials remain uncontaminated and meet regulatory hygiene standards during processing. Designed for easy cleaning, with smooth surfaces and no hidden areas where bacteria can grow, Hygienic Valves prevent contamination during fluid transfer, guaranteeing the safety and quality of the end product. These valves are essential for facilities that require strict compliance with health and safety standards.

Get A Quote