- Home

- About Us

-

Products

-

Sanitary Valve

- Split butterfly valve

- Rapid transfer port(RTP)

- Sanitary diaphragm valve

- Aseptic mixproof valve

- Inflatable seal segment ball valve

- Angle seat valve

- Aseptic powder valve

- Directional valve

- Pressure control valve

- Sanitary ball valve

- Sanitary butterfly valve

- Sanitary check valve

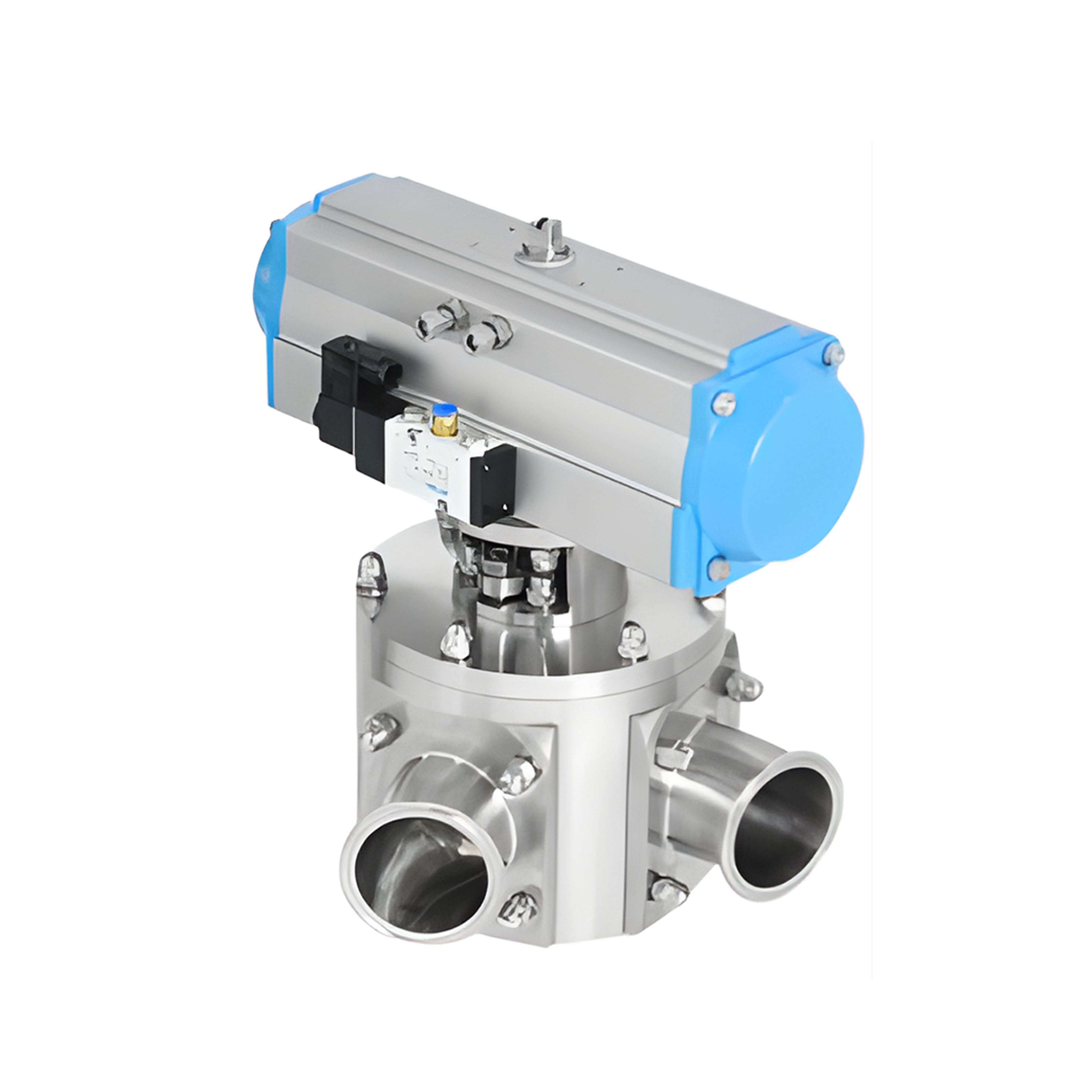

- Sanitary divert valve

- Sanitary globe valve

- Sanitary safty valve

- Sanitary sampling valve

- Sanitary tank buttom valve

- Filter

- Sanitary Pump

- Tank cleaning equipment

- Sight Glass

- Sanitary Fitting

-

Sanitary Valve

- News

- Case

- Contact