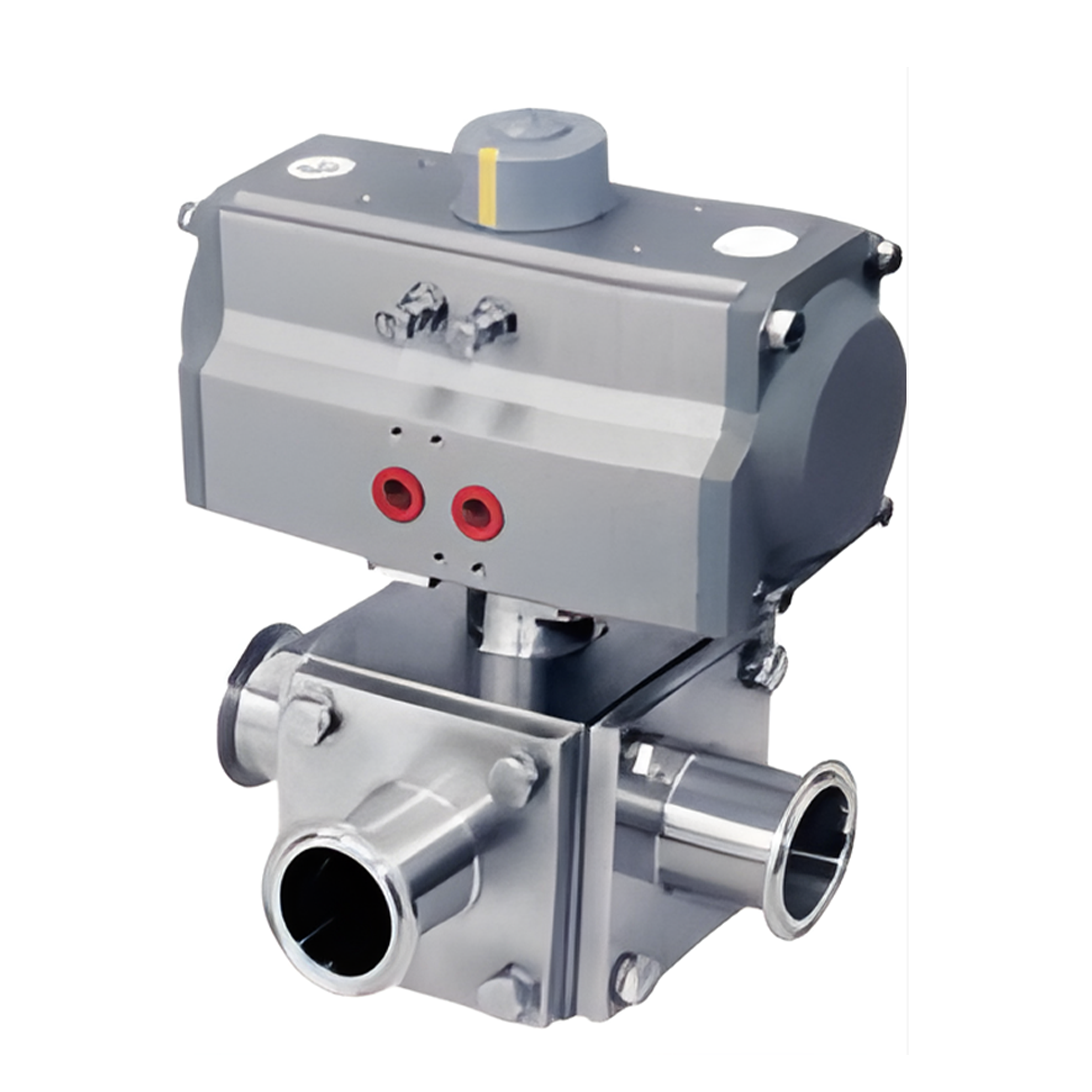

AB Valves for Precise Fluid Switching in Automated Production Lines

AB Valves are essential components in systems where fluid flow needs to be directed between two paths. These valves are widely used in industries that require fast, precise fluid control, including chemical processing, food production, and pharmaceuticals. AB Valves offer the flexibility to change flow directions based on production requirements, ensuring smooth operation of automated systems. With their ability to quickly switch fluid flow, these valves help optimize production processes, ensuring that different stages of production are efficiently managed without interruptions.

Get A Quote