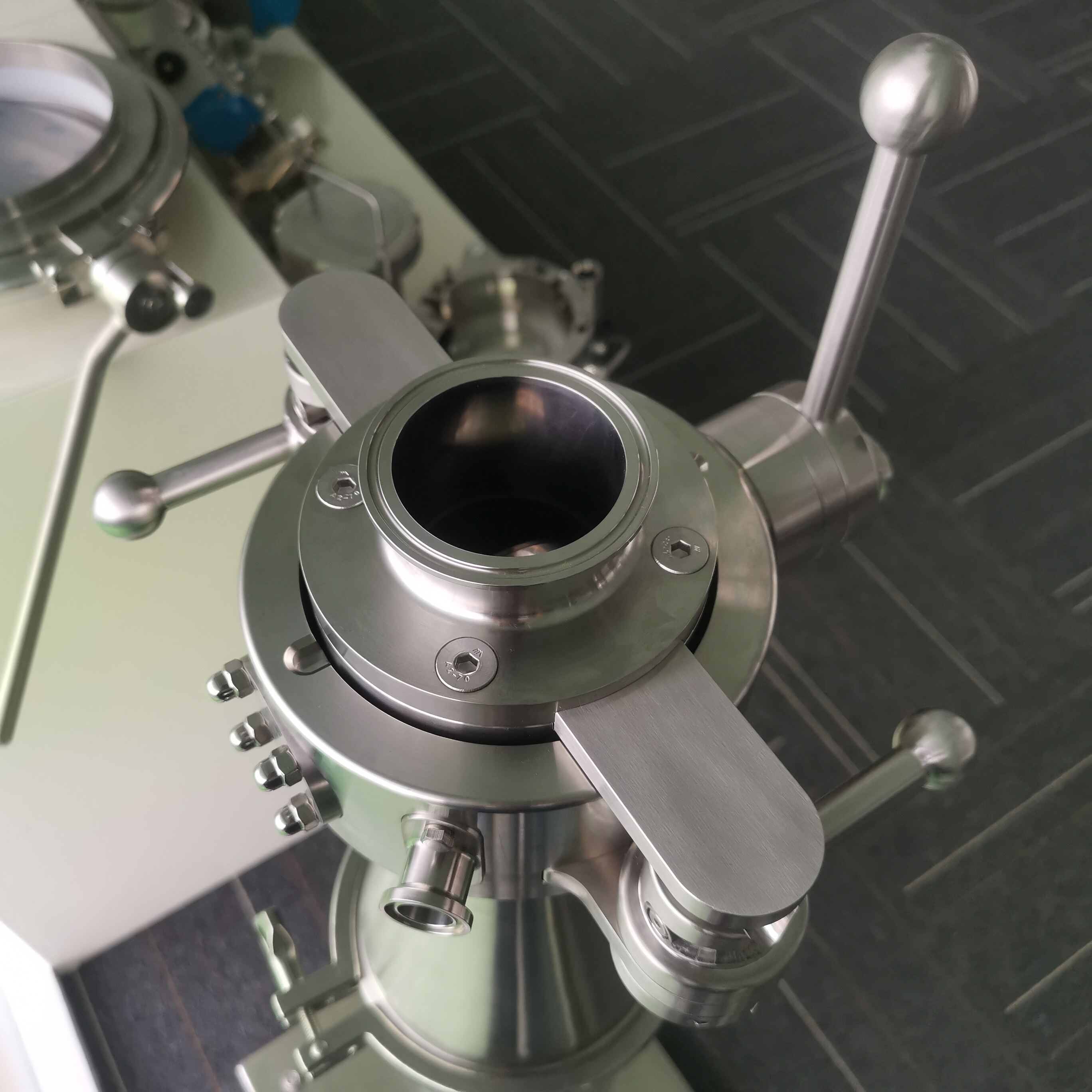

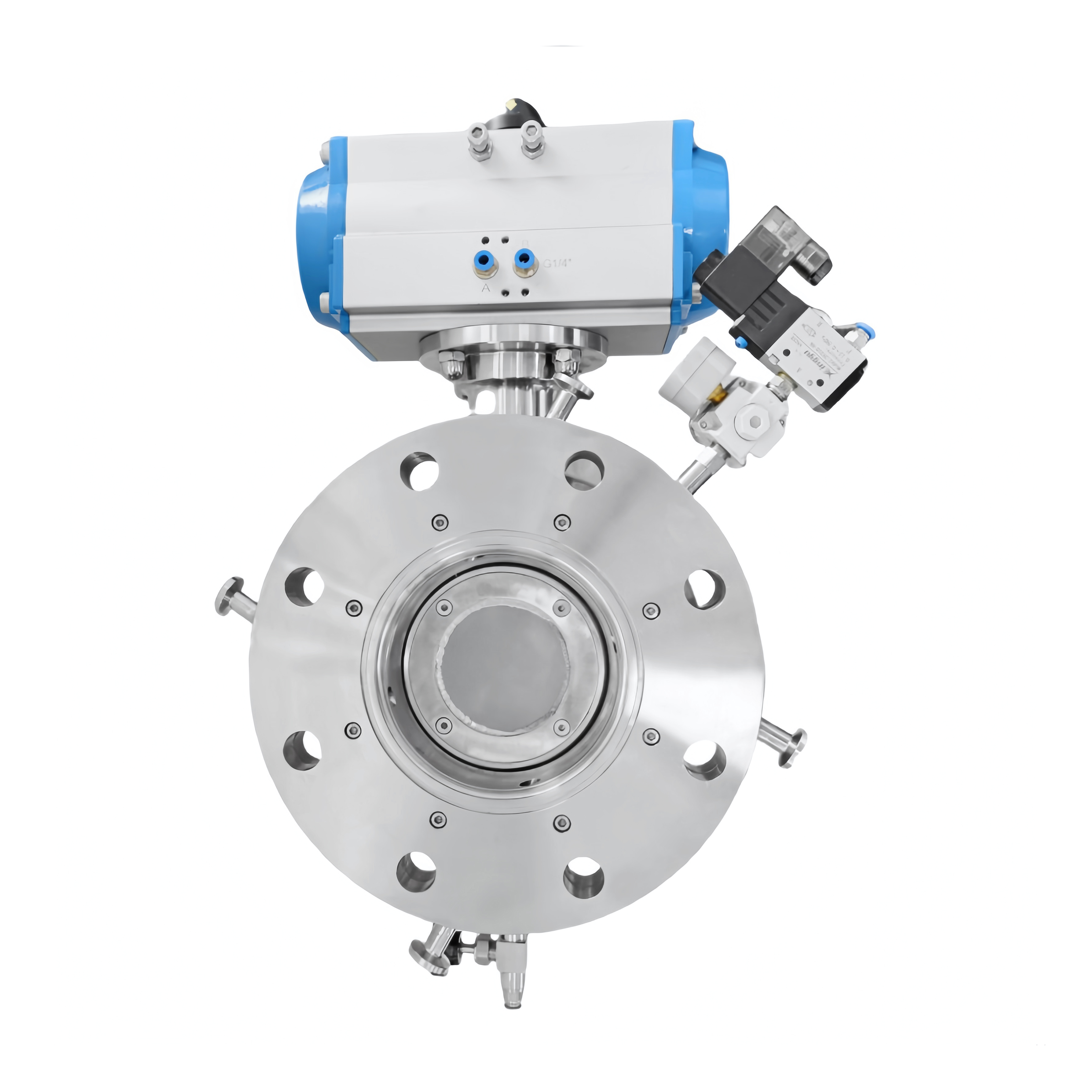

Flexible AB Valves for Fluid Flow Switching in Automated Systems

AB Valves are ideal for fluid switching applications, enabling precise control over the flow direction between two distinct fluid channels. These valves provide flexibility in automated systems where the flow needs to be switched efficiently and without disruption. Widely used in chemical processing, automated production lines, and fluid control systems, AB Valves offer accurate, fast, and reliable performance. They are particularly useful in systems where multiple steps or stages are involved in the production process, allowing for seamless fluid switching to maintain operational efficiency. Their robust design and adaptability ensure that they perform well in a wide range of applications, reducing system downtime and enhancing overall productivity.

Get A Quote