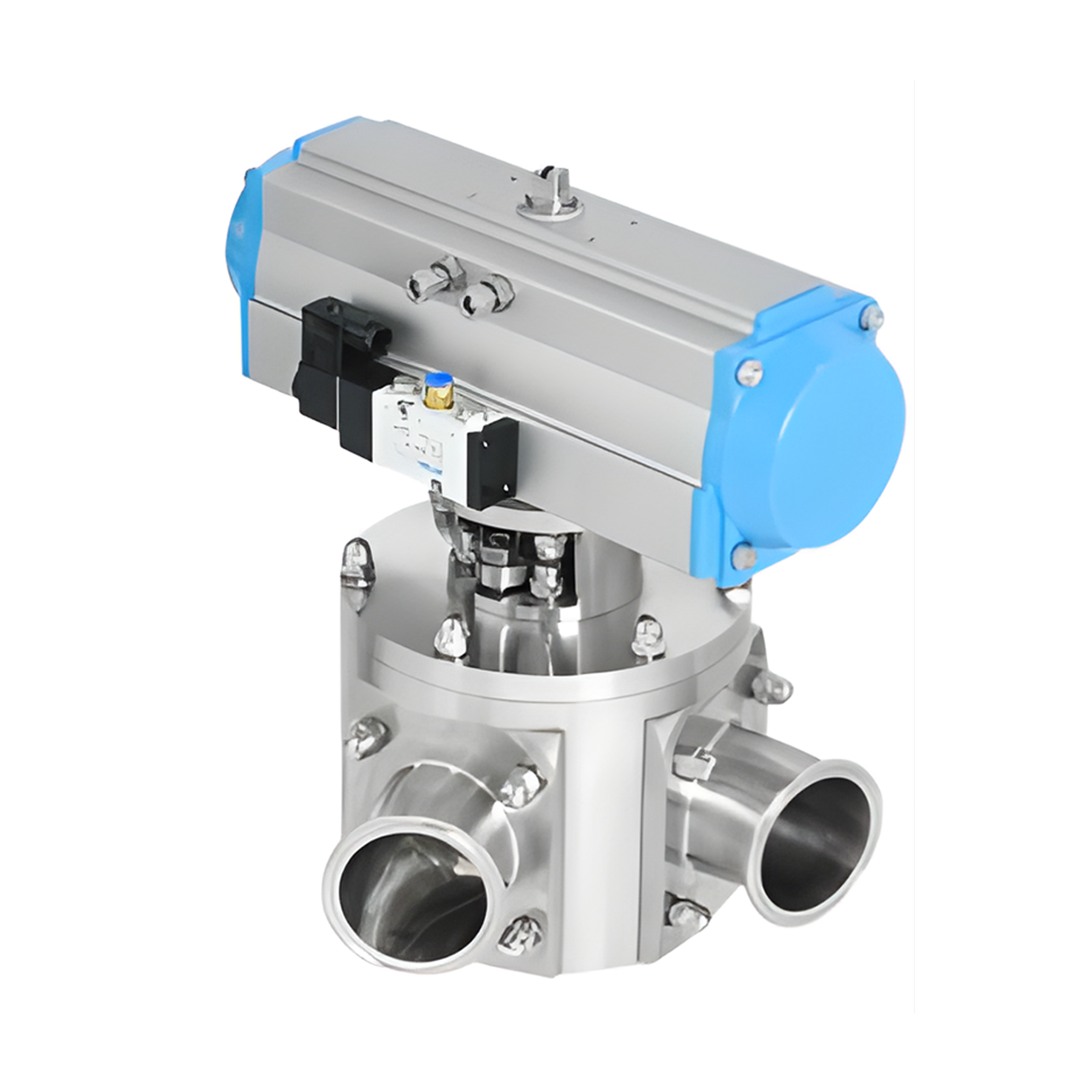

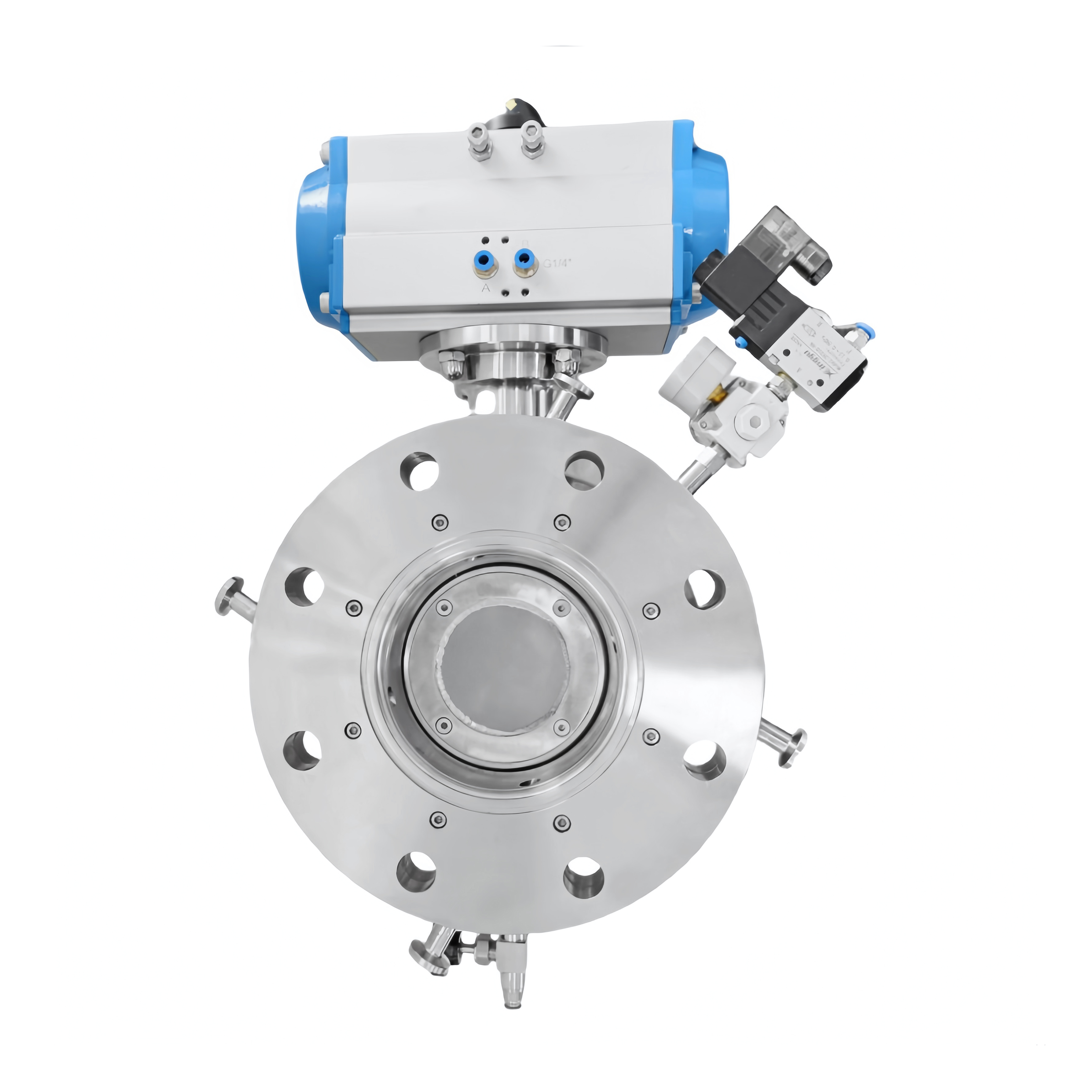

Mixproof Valves: Dual-Seat Isolation for Contamination-Free Operations

Designed with double seats and intermediate seal chambers, AVM's Mixproof Valves prevent media cross-contamination in food, pharma, and chemical processes. Ideal for CIP systems, they create a sterile barrier between cleaning fluids and production streams. Compliant with GMP, FDA, and 3A standards, their robust construction withstands frequent sanitization, while the dual-closure design ensures safety in high-risk applications.