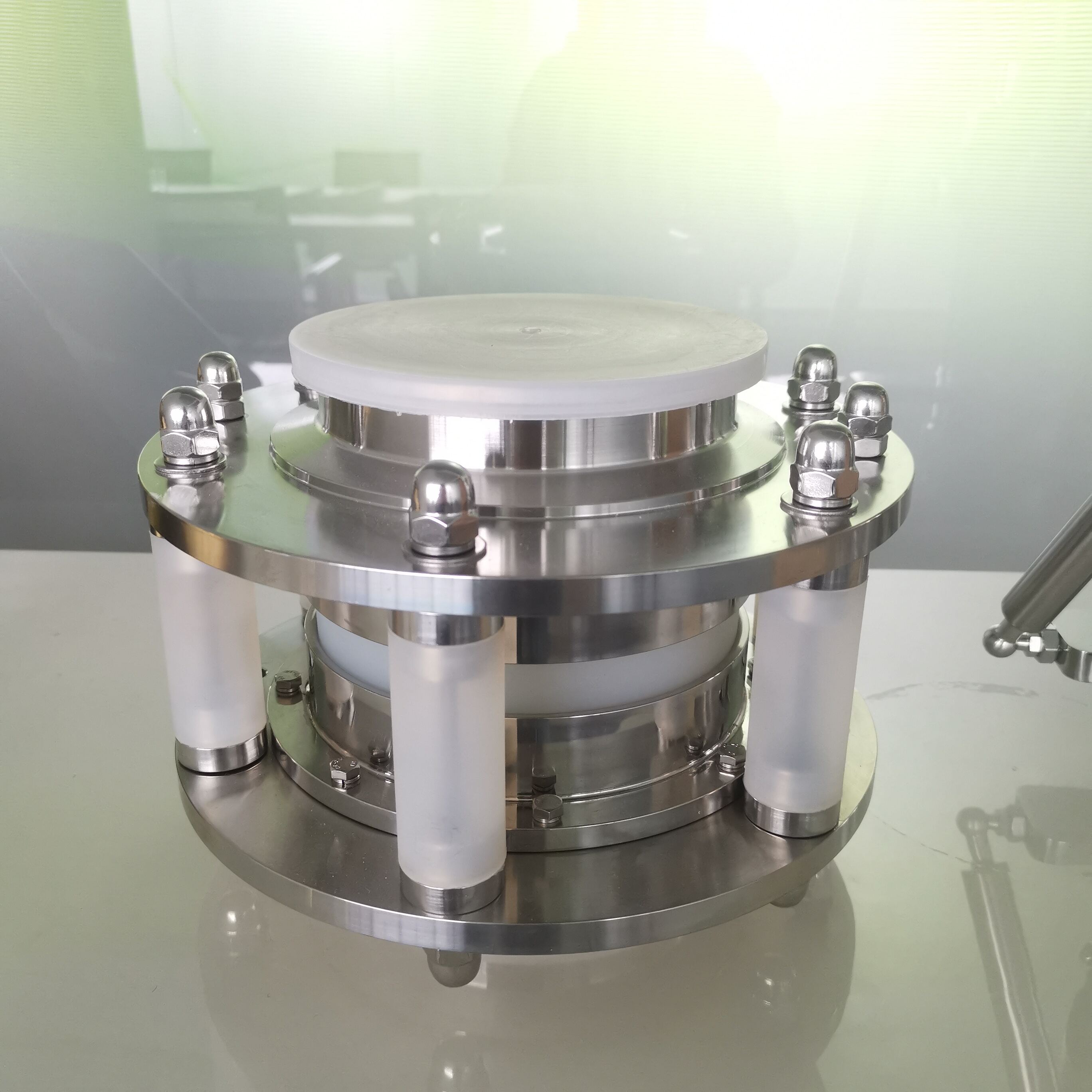

Space-Efficient Split Butterfly Valves for Fluid Control

The Split Butterfly Valve is designed for easy installation and maintenance in confined spaces. Typically used in water treatment, HVAC, and industrial piping systems, this valve is lightweight and compact, making it ideal for systems with space constraints. It provides reliable control over fluid flow with simple installation and offers a cost-effective solution for industrial applications, especially where space and weight are limited.

Get A Quote