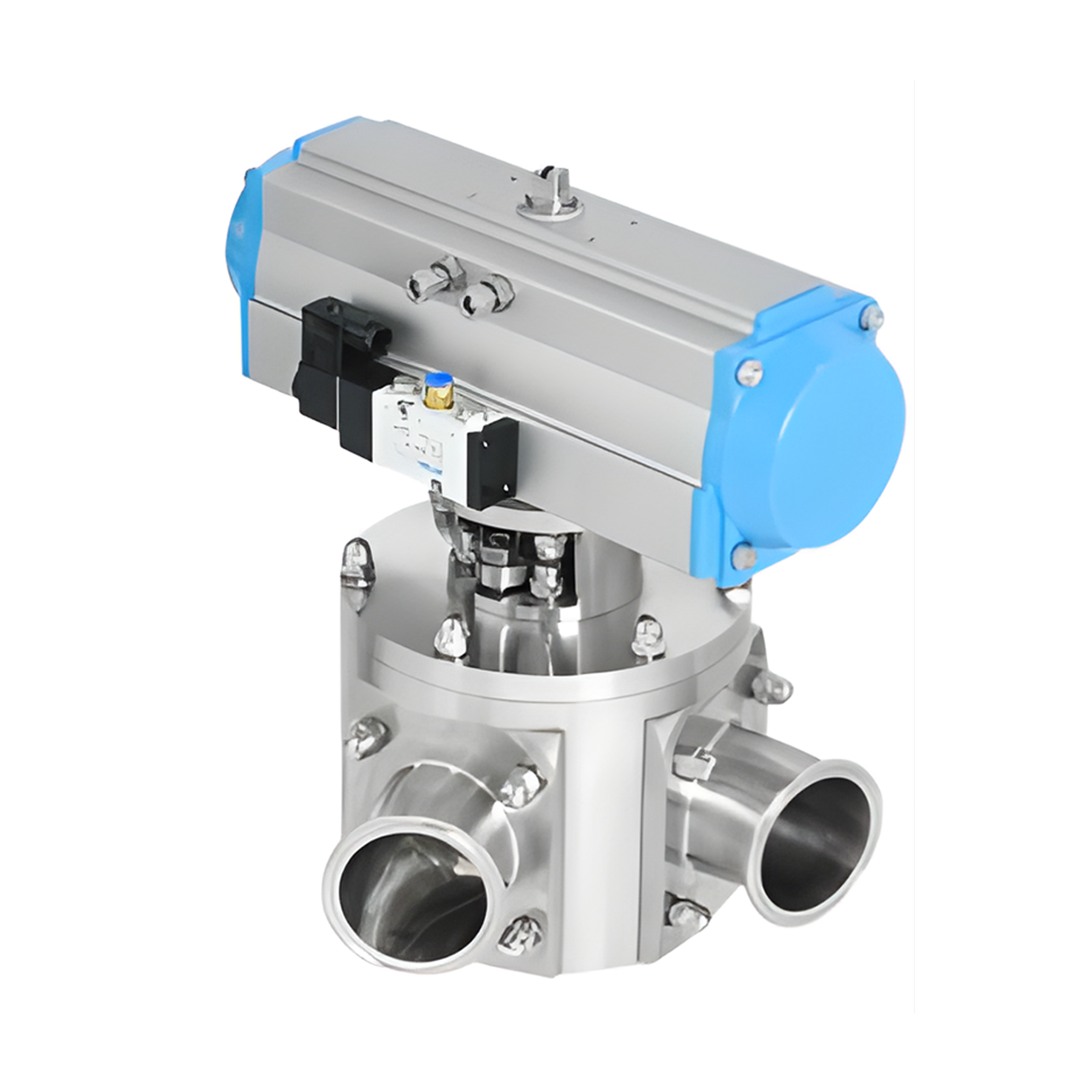

Precision Flow Control with Segment Ball Valves for Heavy-Duty Applications

Segment Ball Valves are ideal for applications that require precise and controlled flow of fluids or gases in industries such as chemicals, oil and gas, and water treatment. The unique fan-shaped ball design provides superior sealing and resistance to abrasive media, making them well-suited for handling highly erosive substances. These valves offer bidirectional flow capabilities, ensuring versatile installation and operation, and they can withstand high pressures, making them perfect for demanding applications. Whether controlling the flow of slurries, gases, or chemicals, Segment Ball Valves offer robust, reliable performance and extended valve life, minimizing the need for frequent maintenance and improving overall system efficiency.

Get A Quote