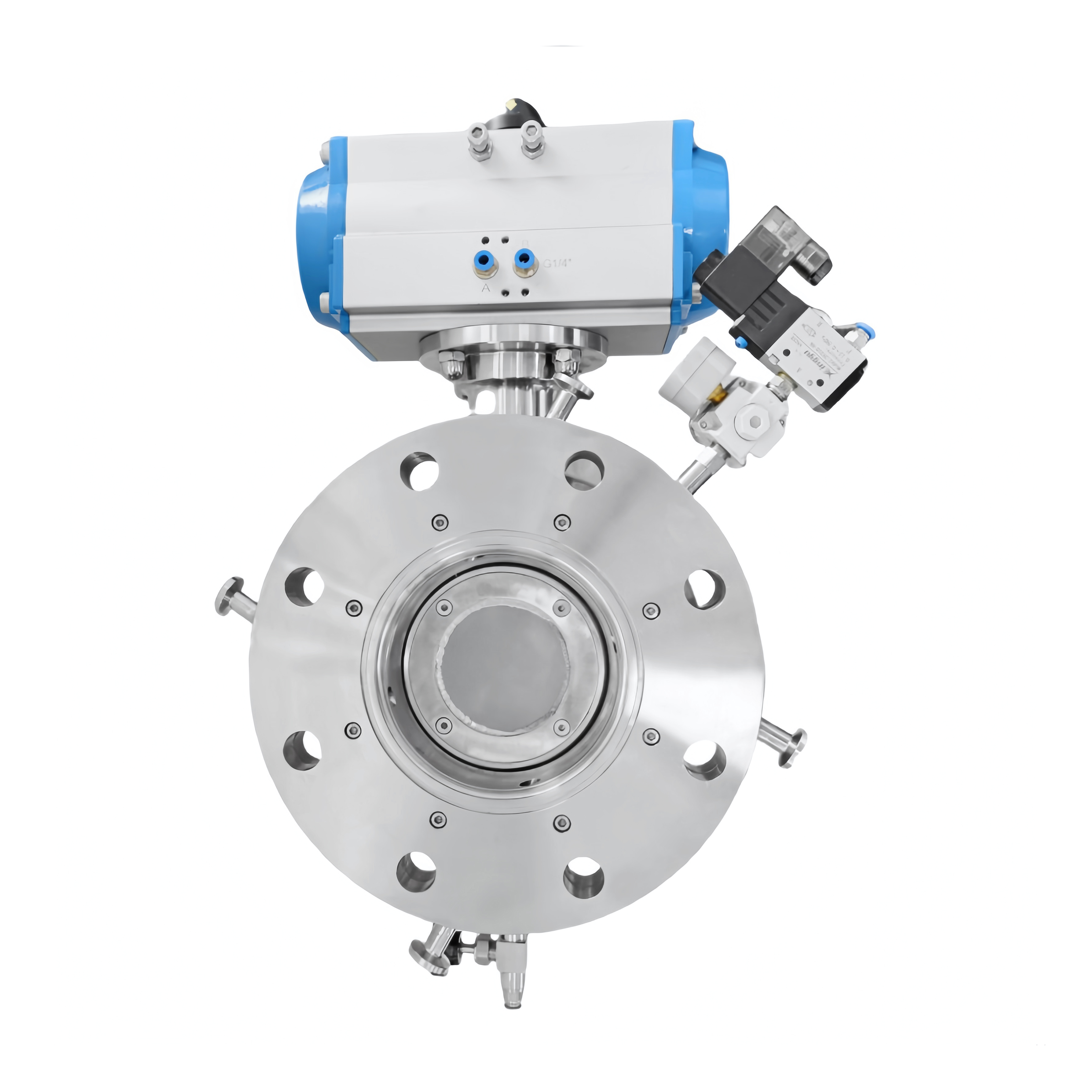

Rotary Valve for Efficient Powder Handling and Flow Regulation

The Rotary Valve is crucial for applications requiring precise powder flow control, such as in food, pharmaceutical, and chemical processing. This valve ensures consistent and accurate material transfer, even under high-volume and high-pressure conditions. Available in various designs, it can be tailored to meet specific processing needs, including the metering, gas-locking, and ingredient mixing. Its robust design ensures efficient operation with minimal downtime, contributing to improved productivity and flow management.

Get A Quote