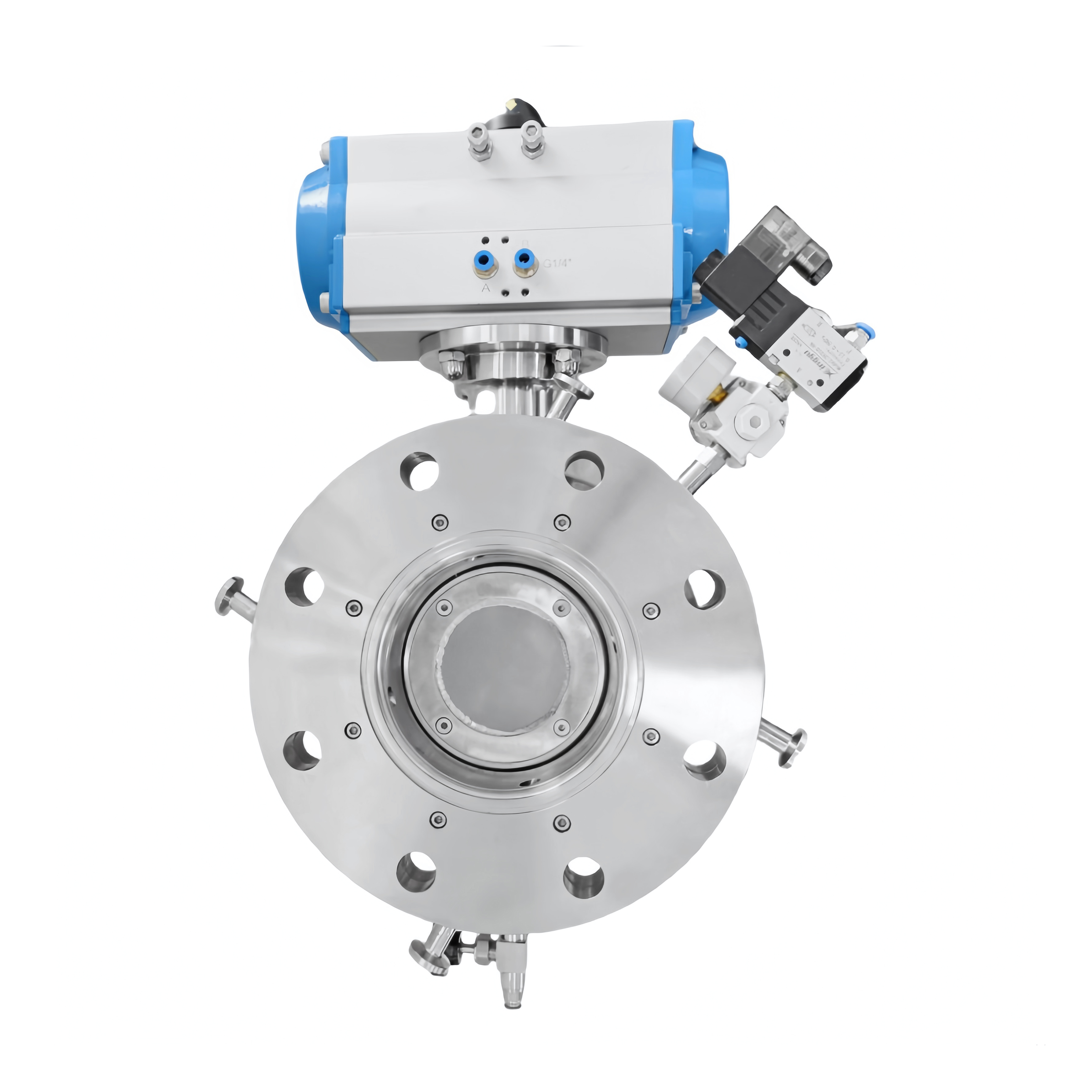

Segment Ball Valve for Precise Control in Harsh Media Applications

The Segment Ball Valve is designed for precise flow control in industries handling abrasive or corrosive media. The unique segment design provides excellent flow regulation, making it perfect for industries like chemicals, oil, and gas. With a robust structure and high flow capacity, it handles high-pressure and high-temperature conditions with ease. This valve excels in applications where high durability and precise regulation of flow are required, ensuring efficiency in harsh environments.

Get A Quote