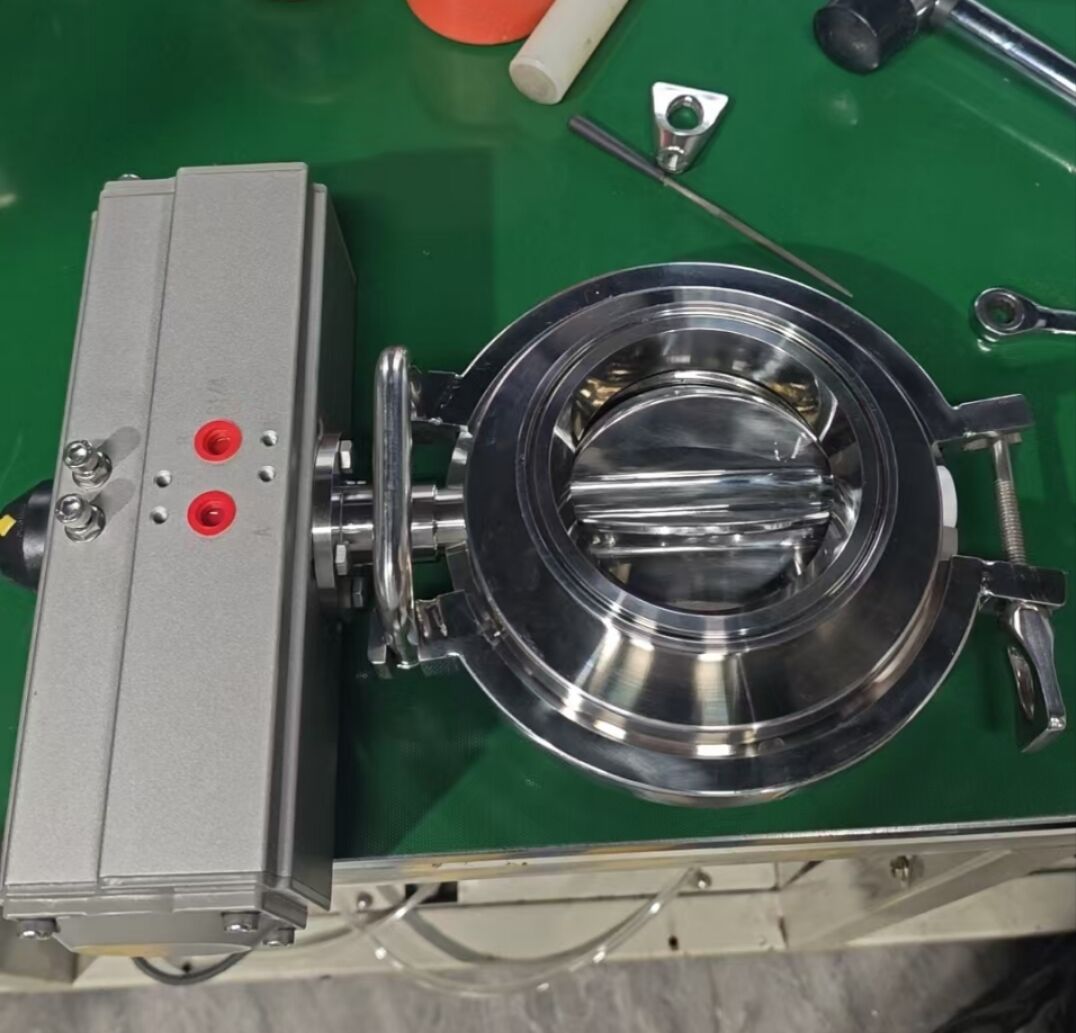

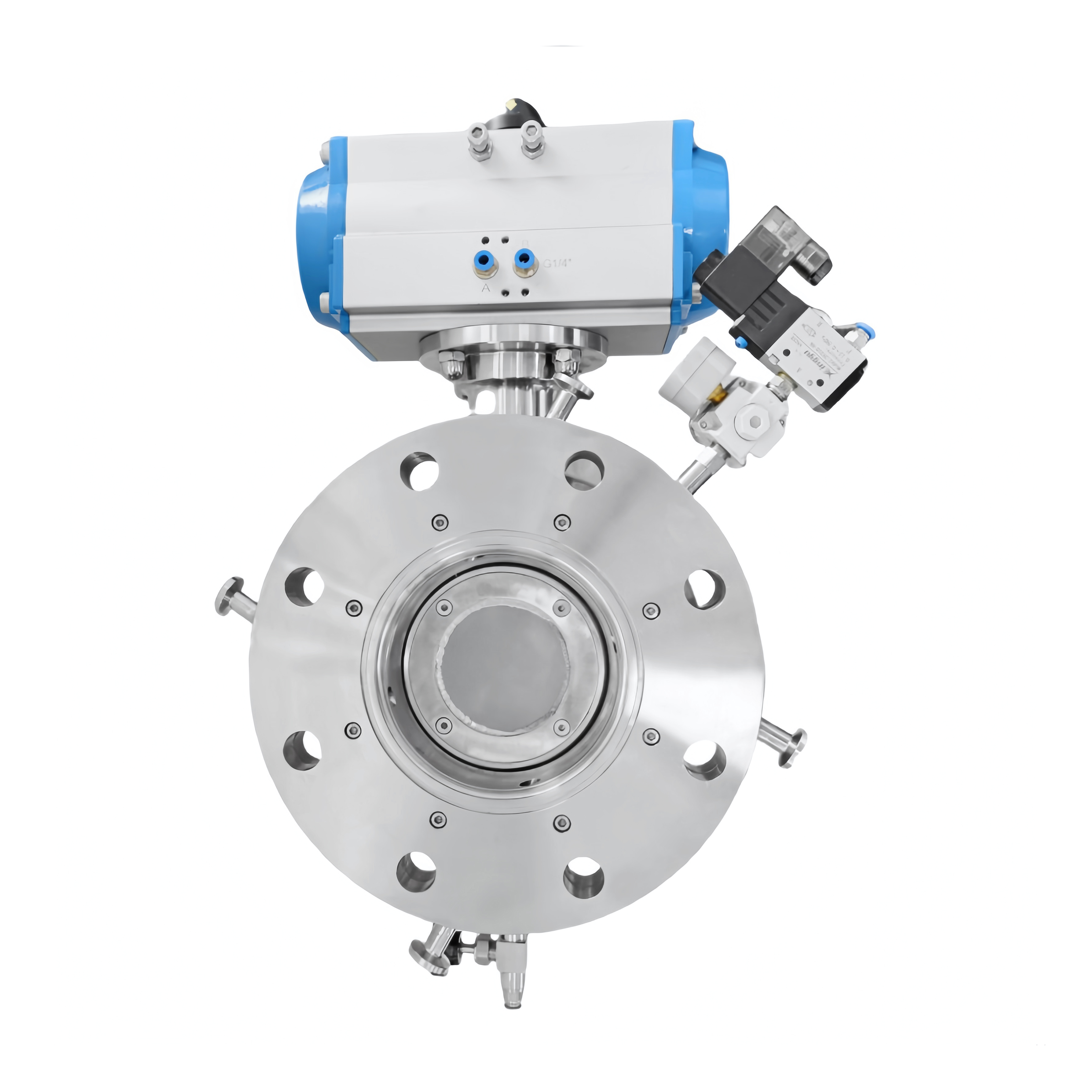

High-Precision Rotary Valves for Powder Handling and Material Flow Control

Rotary Valves are essential for managing the flow of powders, granular materials, and bulk solids in industries like food processing, pharmaceuticals, and chemicals. These valves operate by rotating a rotor inside the valve body, which allows for accurate and controlled material distribution. Available in a range of sizes and rotor designs, Rotary Valves are adaptable to many applications, from small-scale filling systems to large-scale production lines. Their ability to handle high throughput while ensuring consistent, stable material flow makes them a preferred choice for material handling systems. Furthermore, their robust construction and precise design reduce the risk of clogging and ensure long-term, reliable operation in demanding industrial environments.

Get A Quote